Tacky-Adhesive Composition

A pressure-sensitive adhesive, pressure-sensitive adhesive layer technology, applied in the direction of adhesive type, ester copolymer adhesive, adhesive, etc., can solve the problem that the polarizing plate is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

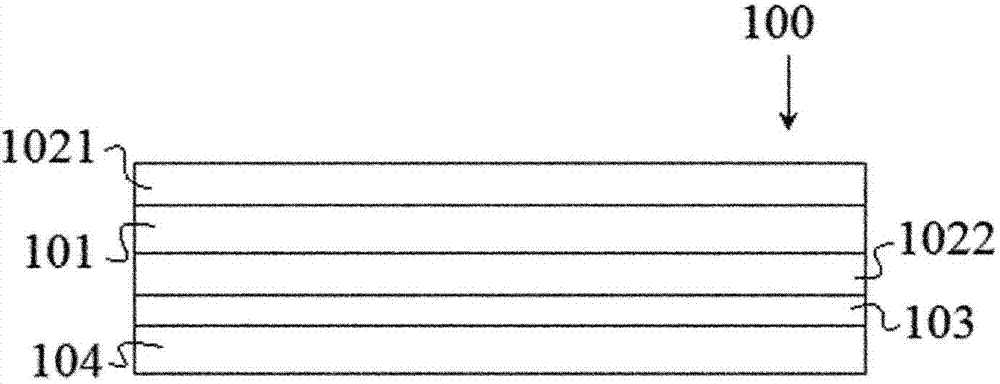

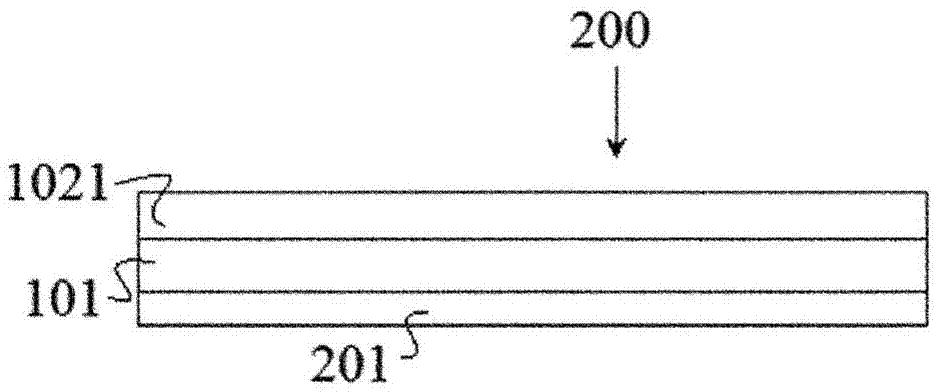

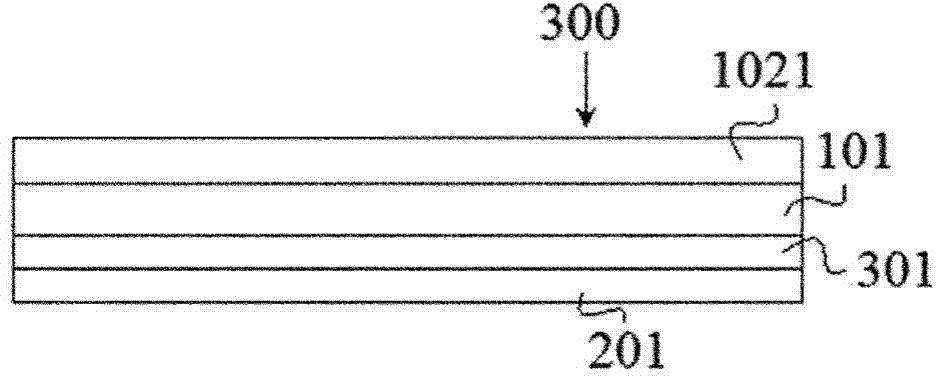

Image

Examples

preparation Embodiment 1

[0111] Preparation Example 1. Preparation of Block Copolymer (A1)

[0112] Mix an appropriate amount of ethyl 2-bromoisobutyrate (EBiB) and methyl methacrylate (MMA) with ethyl acetate (EAc), seal the flask containing the mixture with a rubber membrane, purged with nitrogen and store at 25 °C. Stir for about 30 minutes to remove dissolved oxygen. After that, an appropriate amount of CuBr 2 , tris(2-pyridylmethyl)amine (TPMA) and tin(II) 2-ethylhexanoate (Sn(EH) 2 ) was added to the oxygen-removed mixture and maintained at about 67° C. in the reaction vessel to initiate the reaction (polymerization of the first block). At a conversion of methyl methacrylate of about 70% to 95%, a mixture of butyl acrylate (BA) and hydroxyethyl acrylate (HEA), previously sparged with nitrogen, was added to have the Ratio of final block copolymer. After that, the CuBr 2 , TPMA and Sn(EH) 2 Added to reaction flask for chain extension reaction (polymerization of second block). When the con...

preparation Embodiment 2 and 3

[0113] Preparation Examples 2 and 3. Preparation of Block Copolymers (B1 and C1).

[0114] A block copolymer was prepared by the same method as described in Preparation Example 1 except controlling the monomer weight ratio of the first block to the second block as shown in Table 1.

[0115] [Table 1]

[0116]

preparation Embodiment 4

[0117] Preparation Example 4. Preparation of Random Copolymer (D1)

[0118] Random copolymers were prepared by adding a monomer mixture comprising butyl acrylate (BA) and 2-hydroxyethyl acrylate (HEA) in a ratio of 80:20 (BA:HEA) to a cooling unit equipped with In a 1-liter reactor with nitrogen reflux and temperature control, add an appropriate amount of n-dodecylmercaptan under molecular weight control, then add ethyl acetate as a solvent, purify with nitrogen for about 60 minutes to remove oxygen, add Azobisisobutyronitrile (AIBN) was used as an initiator while maintaining the temperature at 60° C., and the reaction was performed for about 8 hours. The prepared random copolymer (B4) had a number average molecular weight (Mn) of about 220,000 and a polydispersity index (PDI) of about 5.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com