A kind of anti-wet skid low rolling resistance thermoplastic polyurethane elastomer and preparation method

A thermoplastic polyurethane and elastomer technology, which is applied in the field of preparation of polyurethane elastomer materials, can solve the problems of non-repeatable processing and the problem of tire devil triangle, and achieves reduced processing energy consumption, simple and easy preparation method, and excellent moisture resistance. slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

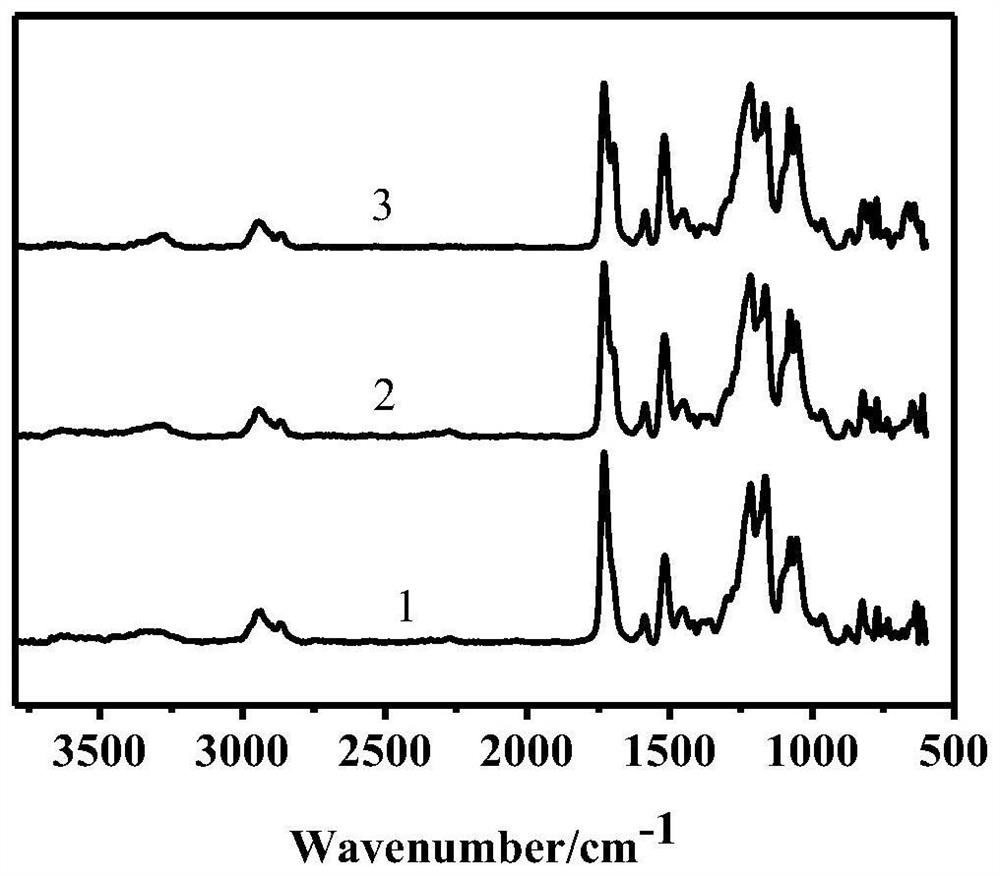

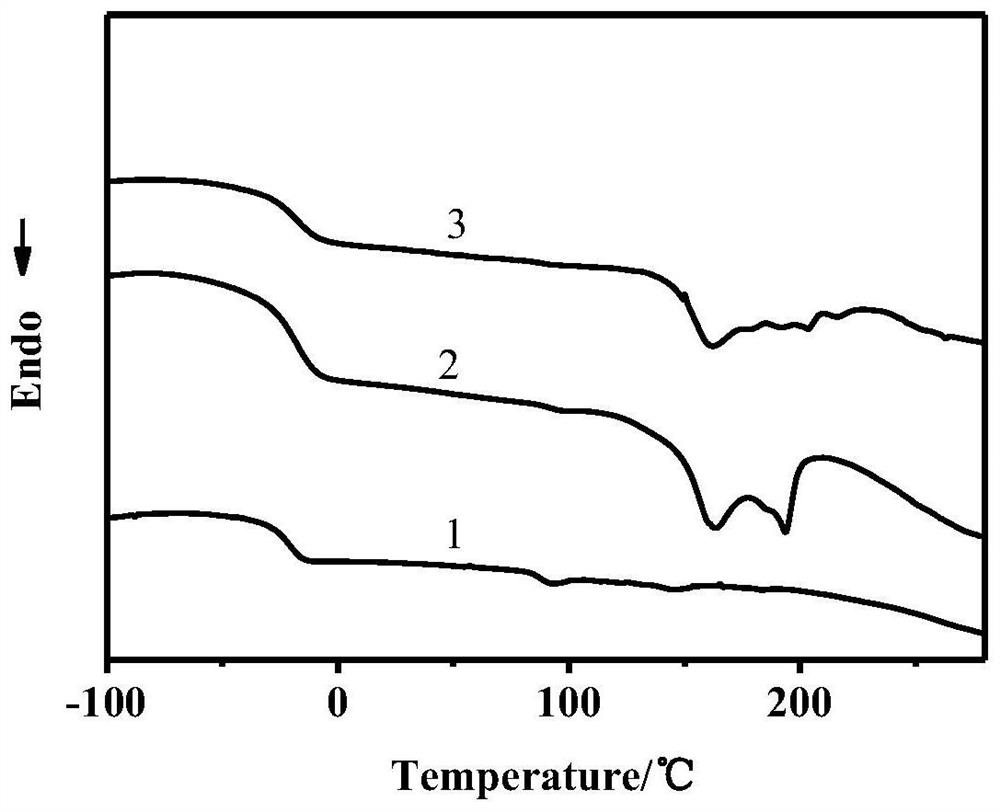

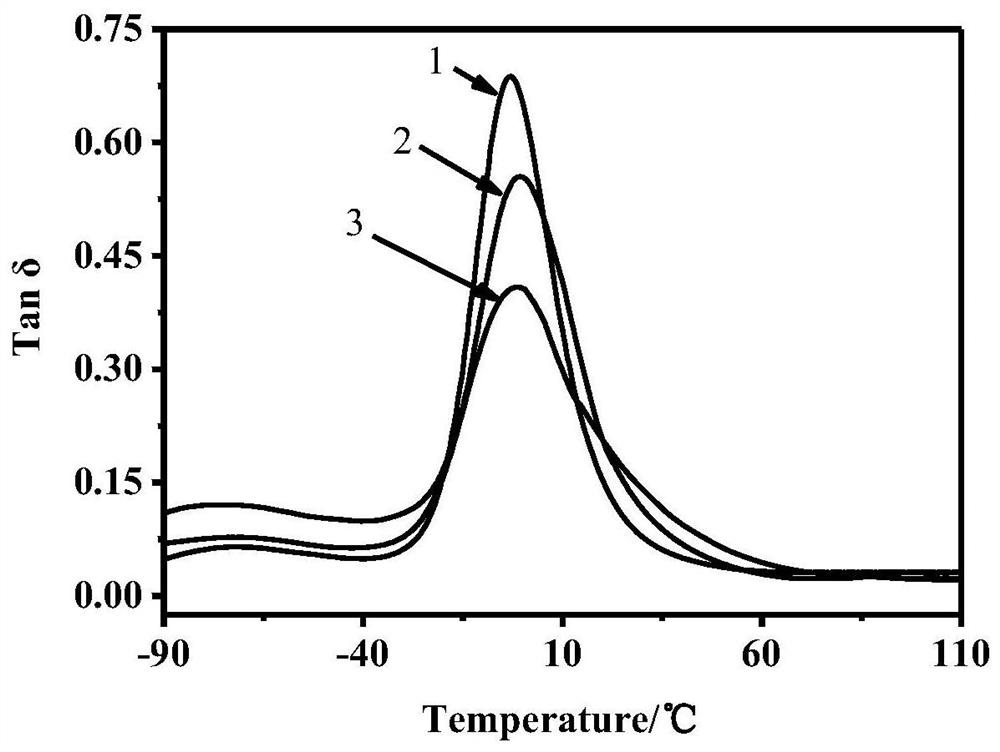

[0043] This example provides a method for preparing a low-hardness TODI-based thermoplastic polyurethane elastomer, using polycaprolactone diol with Mn=1000 as the soft segment, and using dimethyl diphenyl diisocyanate (TODI) and 1,4-butyl Diol (BDO) is the hard segment, and the molar ratio of polycaprolactone diol: TODI and 1,4 butanediol is designed to be 1:1.7:0.7 (molar ratio), and TODI-based thermoplastic polyurethane is prepared by prepolymer method Elastomer:

[0044] (1) Remove water from 132g of polycaprolactone diol (Mn=1000) at -0.097MPa, 100°C with 90r / min mechanical stirring for 1.0h, this step removes the moisture in the raw material;

[0045] (2) After cooling the system to 60°C, add 59.57g of dimethyl biphenyl diisocyanate and 0.01g of dibutyltin dilaurate as a catalyst, and react for 2 hours after the system is heated up to 60°C to obtain isocyanate-terminated TODI-based polyurethane prepolymerization body;

[0046] (3) Under mechanical stirring at 400r / min,...

Embodiment 2

[0048] This example provides a preparation method of a high-hardness TODI-based thermoplastic polyurethane elastomer, using polycaprolactone diol with Mn=1000 as the soft segment, and dimethyl diphenyl diisocyanate (TODI) and BDO as the hard segment , design polycaprolactone diol: TODI:BDO=1:2.5:1.5 (molar ratio), prepared TODI base thermoplastic polyurethane elastomer by prepolymer method:

[0049] (1) Take 111.2g of polycaprolactone diol with Mn=1000 as the soft segment (Mn=1000) to remove water for 1.5h under the condition of -0.097MPa, 110°C and 110r / min mechanical stirring, and remove the raw materials in this step moisture in

[0050] (2) Add 73.68g of dimethyl biphenyl diisocyanate and 0.02g of dibutyltin diacetate as a catalyst after the system cools down to 80°C, and react for 3 hours after the system is heated up to 80°C to obtain isocyanate-terminated TODI-based polyurethane prepolymer ;

[0051] (3) Add BDO 15.11g, 2-(2'-hydroxy-5'-(2,4-tert-butyl)phenyl)benzotri...

Embodiment 3

[0053] With the polycaprolactone diol of Mn=1000 as soft segment, with dimethyl diphenyl diisocyanate (TODI) and BDO as hard segment, design polycaprolactone diol: TODI:BDO=1:3.5:2.5( mol ratio), prepared TODI-based thermoplastic polyurethane elastomer by prepolymer method:

[0054] (1) Use 93g of polycaprolactone diol as a soft segment (Mn=1000) to remove water for 2.5h under the conditions of -0.095MPa, 120°C and 120r / min mechanical stirring, this step removes the moisture in the raw material;

[0055] (2) After cooling the system to 90°C, add 86.03g of dimethyl biphenyl diisocyanate and 0.03g of zinc isooctanoate as a catalyst, and react for 3 hours after the system is heated up and stabilized to 90°C. In this step, an isocyanate-terminated TODI-based polyurethane prepolymer is obtained;

[0056] (3) Add BDO 20.96g, 2-(2'-hydroxy-5'-(2,4-tert-butyl)phenyl)benzotriazole (UV320) 1g, tetrakis[ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com