Novel clean energy produced via deep processing of sawdust and preparation method of novel clean energy

A clean energy and sawdust technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc., can solve the problems of unfavorable environmental protection, low thermal efficiency, air pollution, etc., achieve low cost of use, high energy consumption, and increase additional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

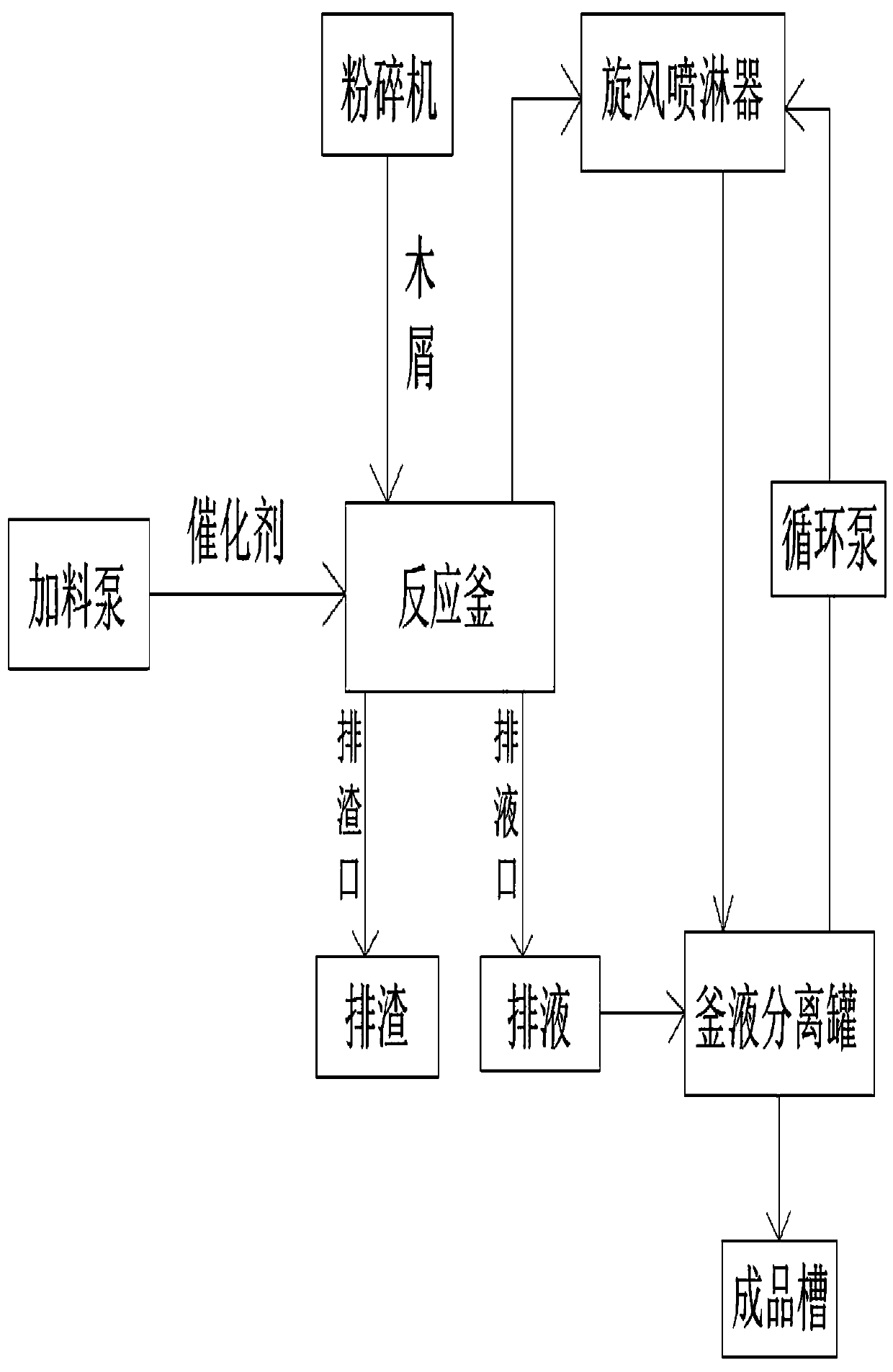

Embodiment 1

[0022] The sawdust produced by the plate processing enterprise is crushed by a pulverizer to make it uniform in particle size, free of impurities, and with a moisture content of 10-14%; the treated sawdust is sent into the reaction kettle, and steam is added for heating and wetting. Control at 75°C, keep the temperature constant for 1 hour, and empty the non-condensable gas; put the catalyst into the container, and then add deionized water, so that the catalyst concentration ratio is 1 / 1000; the prepared catalyst and wood chips are in the ratio of 1:10 Use the pump to uniformly atomize and send it into the reactor, raise the temperature to 90°C, and keep the temperature constant for 8 hours, so that the sawdust can be fermented and decomposed in the reactor, and then fermented and decomposed to produce multi-component fractionated oil. The bottom controls the liquid level, extracts it evenly, and then flows into the kettle liquid separation tank through the liquid discharge por...

Embodiment 2

[0024] The sawdust produced by the plate processing enterprise is crushed by a pulverizer to make it uniform in particle size, free of impurities, and the moisture content is controlled at 10-14%; the treated sawdust is sent into the reaction kettle, and steam is added for heating and wetting. The temperature was controlled at 80°C, kept at constant temperature for 1 hour, and the non-condensable gas was evacuated; the catalyst was put into the container, and then deionized water was added to make the catalyst concentration ratio 1 / 1000; the prepared catalyst and wood chips were mixed according to the ratio of 1:10 The ratio is uniformly atomized and sent into the reaction kettle by pump, the temperature is raised to 95°C, and the temperature is kept constant for 8 hours, so that the wood chips are fermented and decomposed in the reaction kettle, and then fermented and decomposed to produce multi-component fractionated oil. After the reaction kettle is cooled to 35°C, the The l...

Embodiment 3

[0026] The sawdust produced by the plate processing enterprise is crushed by a pulverizer to make it uniform in particle size, free of impurities, and the moisture content is controlled at 10-14%; the treated sawdust is sent into the reaction kettle, and steam is added for heating and wetting. The temperature was controlled at 82°C, kept at constant temperature for 1 hour, and the non-condensable gas was evacuated; the catalyst was put into the container, and then deionized water was added to make the catalyst concentration ratio 1 / 1000; the prepared catalyst and wood chips were mixed according to the ratio of 1:10 The ratio is uniformly atomized by a pump and sent to the reactor, the temperature is raised to 98°C, and the temperature is maintained for 8 hours, so that the wood chips are fermented, decomposed and matured in the reactor, and then fermented and decomposed to produce multi-component fractionated oil. After the reactor is cooled to 35°C, the The liquid level is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com