a tio 2 Preparation method of /zns double-layer composite nanotube array

A nanotube array, double-layer composite technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as easy agglomeration, band gap, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

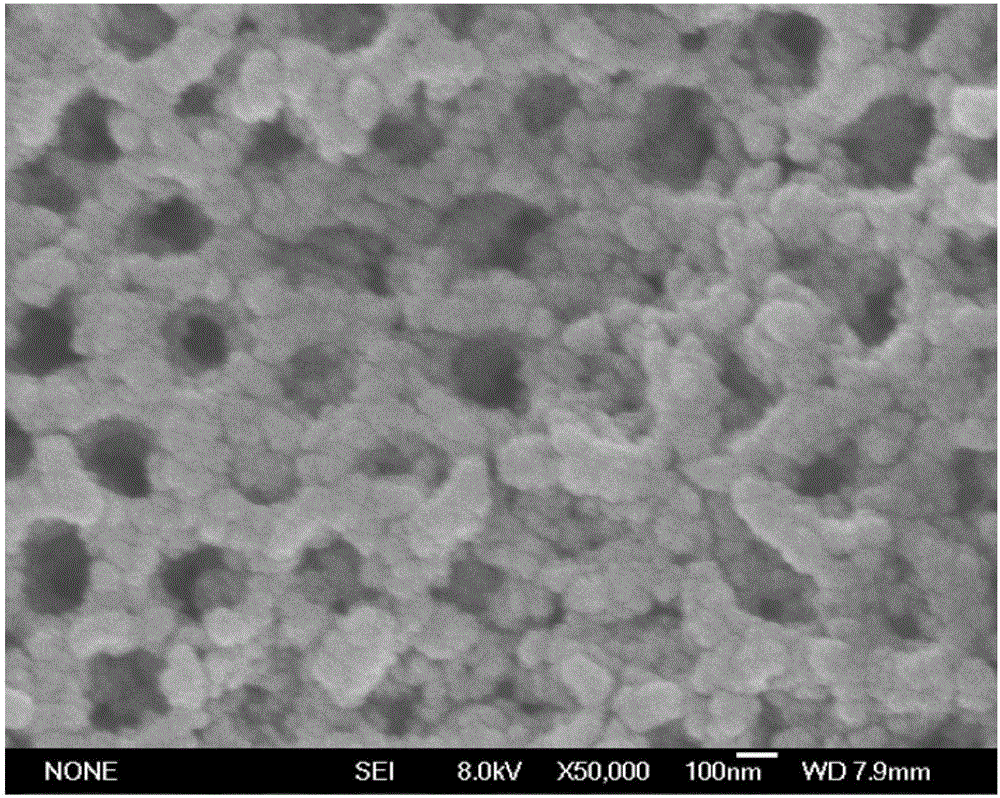

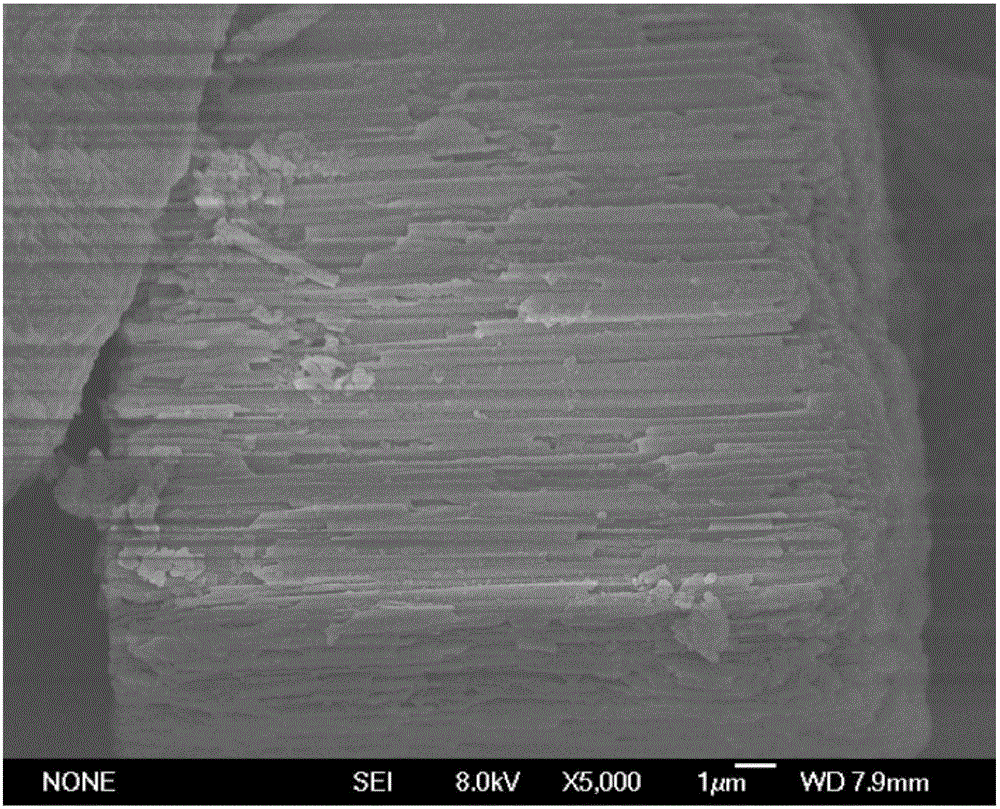

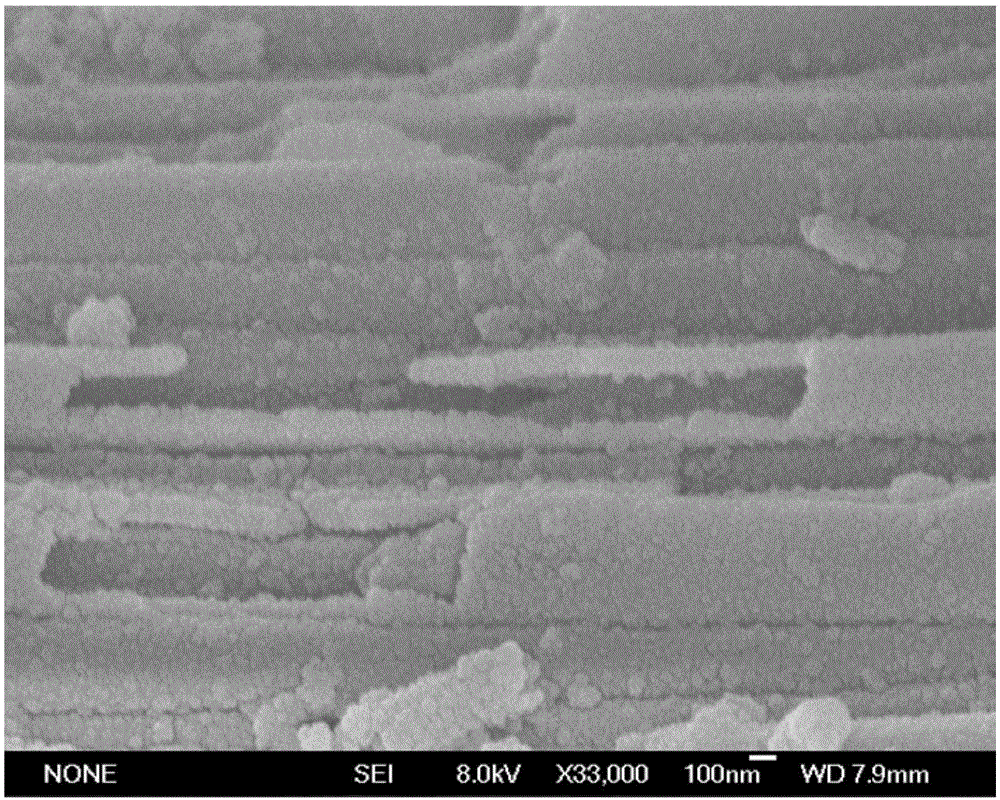

[0026] Prepare 0.04M TiF in a beaker 4 solution, heated TiF 4 The solution was brought to 60°C, and the anodized aluminum template was completely immersed to keep the immersion time for 9 minutes. Then the samples were taken out and placed in an oven at 80°C for 1 h to dry. will subsequently be loaded with TiO 2 The precursor anodized alumina template was immersed in 0.04M Zn(CH 3 COO) 2 and 0.04M Na 2 S 2 o 3 In the mixed solution, hydrothermal reaction was carried out in a polytetrafluoroethylene-lined hydrothermal kettle, the hydrothermal temperature was 180°C, and the reaction time was 6h. After taking out the sample, wash it with deionized water and dry it to get the ZnS nested in TiO 2 TiO in nanotubes 2 / ZnS bilayer composite nanotube arrays. Depend on figure 1 It can be clearly seen that TiO 2 The inner and outer walls of the / ZnS double-layer composite nanotube have a wall thickness of about 60nm and a pore diameter of about 200nm. Depend on figure 2 It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com