Sound absorbing and noise reducing material and transformer vibration isolating and noise reducing device

A transformer and noise reduction technology, which is applied in the field of sound-absorbing and noise-reducing materials and transformer vibration-isolation and noise-reducing devices, can solve the problems of short service life of the base, lack of moisture-proof, anti-corrosion, pollution, etc., and achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

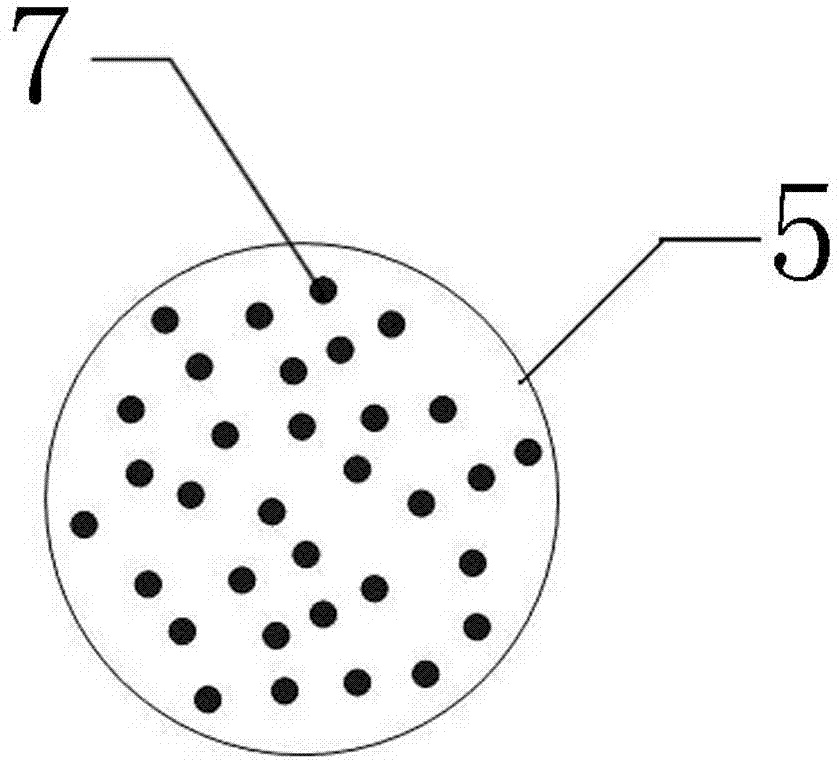

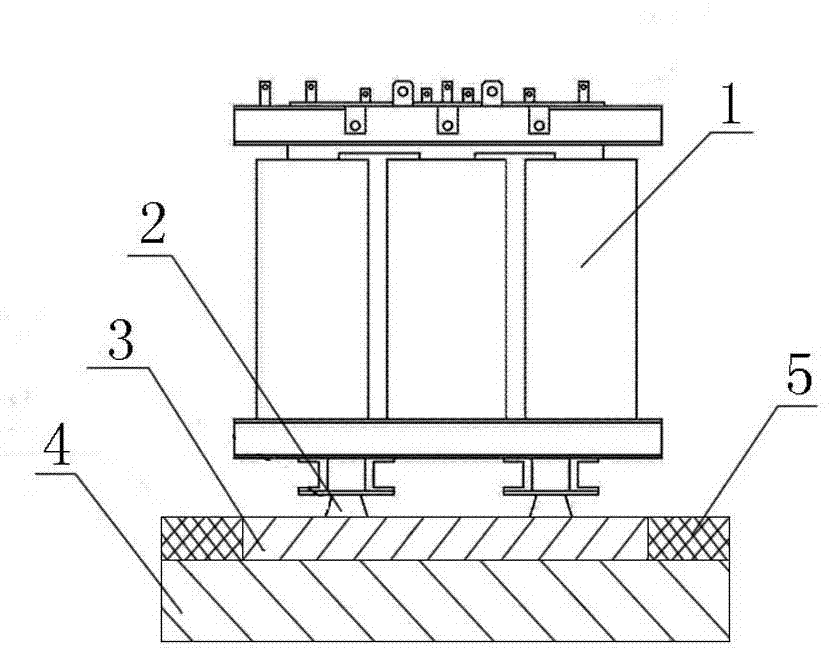

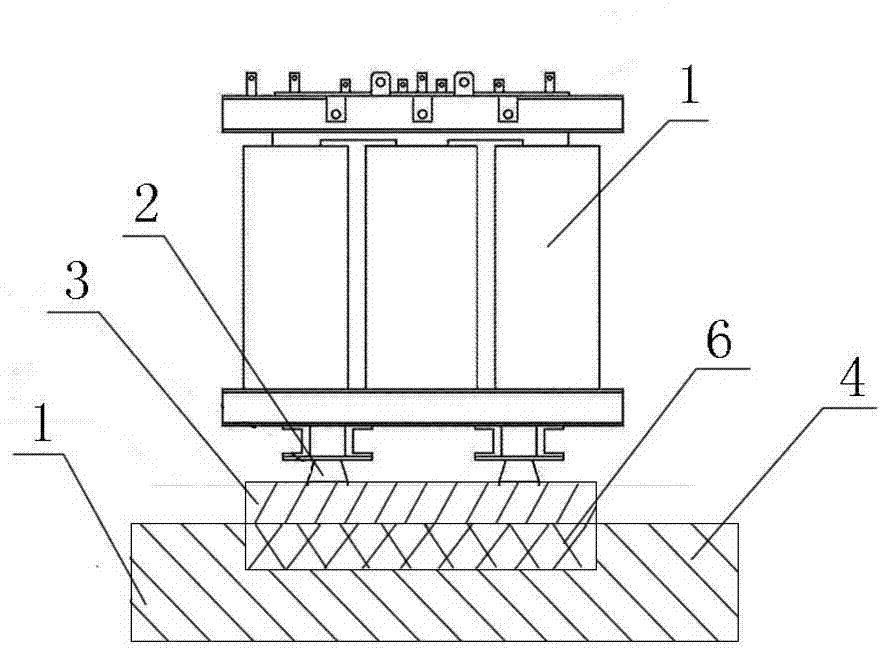

[0019] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 As shown, a sound-absorbing and noise-reducing material according to the present invention is mainly composed of asphalt, organosilicon, microporous ceramics and microporous glass beads. The asphalt and organosilicon are mixed fillers, which are used as sound-absorbing materials The mixture of microporous ceramics and microporous glass beads is mixed according to the following weight percentage: that is, 20-90% of asphalt and organosilicon mixed with microporous ceramic fillers and 10-80% of microporous ceramics and microporous glass beads Mix and make a sound-absorbing and noise-reducing material 5 with certain strength and adhesiveness.

[0020] The microporous ceramics and microporous glass beads are all round or ring-shaped granular 7, and a large number of communicating or closed air holes that can absorb high-frequency sound waves are formed inside.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com