Dry-quenched mullite brick and preparation method thereof

A mullite brick and coke CDQ technology, which is applied in the field of CDQ mullite brick and its preparation, can solve the problem that the coke quenching process of CDQ coke oven is not satisfied, the strength and wear resistance are not too high, and the fire resistance is reduced. The service life of materials and other issues can be improved to improve high-temperature volume stability and high-temperature performance, improve thermal shock resistance, and increase strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The application also provides a preparation method for CDQ coke mullite bricks, comprising the following steps:

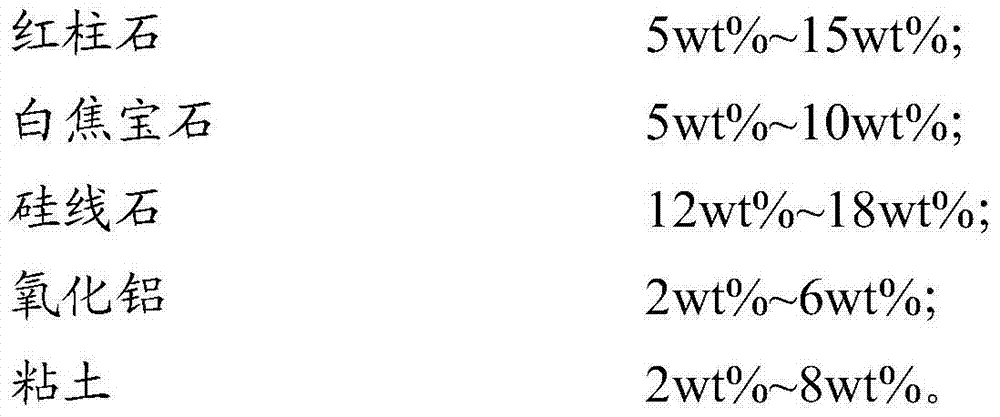

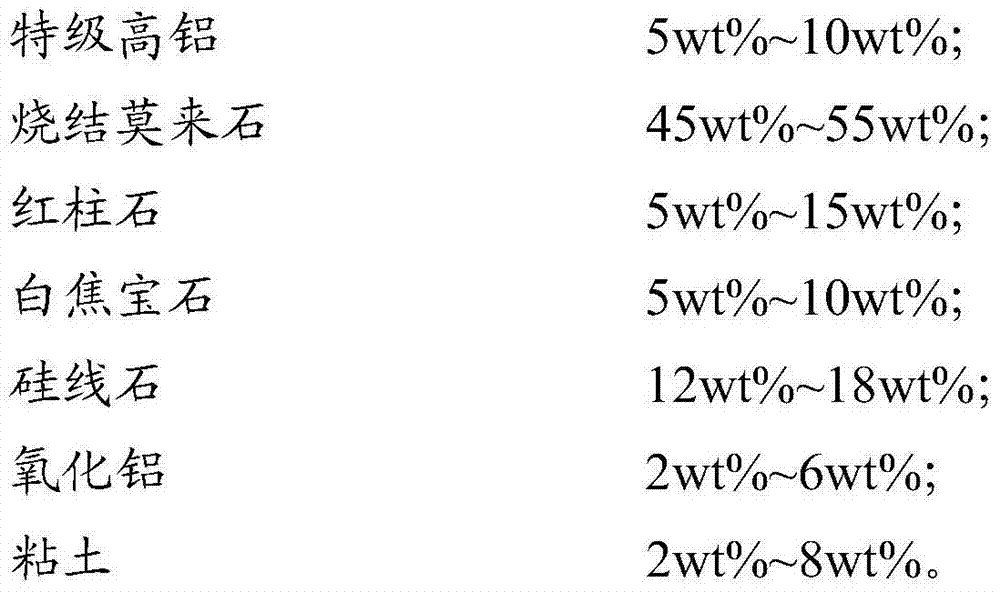

[0033] 5wt% to 10wt% super high alumina, 45wt% to 55wt% sintered mullite, 5wt% to 15wt% andalusite, 5wt% to 10wt% white coke gem, 12wt% to 18wt% sillimanite , 2wt% to 6wt% of alumina, 2wt% to 8wt% of clay are mixed with pulp water to obtain mud;

[0034] The mud is pressed into shape and then dried, and the dried brick adobe is fired to obtain CDQ coke mullite bricks.

[0035] In the process of preparing CDQ coke-mullite bricks, the present application firstly prepares mud material mixed with raw materials, and then compresses, dries and burns the mud material to obtain CDQ coke-mullite bricks.

[0036] In the process of preparing CDQ coke mullite bricks, based on sintered mullite, the sintered mullite preferably contains 11wt% to 21wt% of sintered mullite particles with a particle size of 3 to 5mm, and 28wt% ~38wt% of sintered mullite particles with a par...

Embodiment 1

[0049] The CDQ coke-mullite brick of the present invention is represented by weight percentage. The CDQ coke-mullite brick is composed of 7% super high alumina, 51% all-natural sintered mullite, 10% andalusite, white coke gem 8%, sillimanite 15%, alumina micropowder 4% and bonded clay 5%.

[0050] Among them, the super high alumina is 5~3mm pellets from Shanxi rotary kiln, 51% of all natural sintered mullite is made of 8% sintered mullite pellets with a particle size of 5~3mm, 17% sintered mullite pellets with a particle size of 3~1mm 10% sintered mullite granules with a particle size of 1-0 mm and 16% sintered mullite fine powder with a particle size of -200 mesh. The andalusite is composed of 5% andalusite granules with a particle size of 3-1mm and 5% andalusite granules with a particle size of 1-0mm, and is produced in South Africa. The white burnt gemstone is YNS44 grade, and the particle size is 3-1mm. The sillimanite is Lingshou sillimanite with a particle size of -200...

Embodiment 2

[0066] The same as Example 1, the difference is that: CDQ coke-mullite brick of the present invention, represented by weight percent, consists of 10% super-high alumina, 49% all-natural sintered mullite, 13% andalusite, and white coke gem 6%, sillimanite 13%, alumina micropowder 5% and bonded clay 4%.

[0067] Among them, the all-natural sintered mullite is composed of 6% sintered mullite particles with a particle size of 5-3mm, 14% sintered mullite particles with a particle size of 3-1mm, 12% sintered mullite particles with a particle size of 1-0mm and 17% % Granularity - Composition of 200 mesh sintered mullite fine powder. The andalusite is composed of 8% andalusite granules with a particle size of 3-1mm and 5% andalusite granules with a particle size of 1-0mm, and its origin is Xinjiang. Alumina micropowder is active type with a particle size of -5μm. The combined clay is Suzhou white clay with a particle size of -200 mesh. The properties of the CDQ pyromullite bricks p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com