Ultraviolet LED lamp encapsulating glue and preparation method thereof

A LED lamp packaging and glue technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of large light attenuation, bluish luminous hue of purple LED, aging and attenuation of chips, etc., to achieve high color rendering, Good effect, less heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of a purple light LED lamp packaging glue involved in this embodiment comprises the following steps:

[0030] (1) Weigh one or both of bisphenol A type epoxy resin and cycloaliphatic epoxy resin, add polyethylene glycol epoxy resin, optical brightening agent, defoamer to it and mix uniformly, prepare into A agent;

[0031] (2) dissolving the accelerator in the agent B additive to make an intermediate, weighing one or both of methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride, and mixing them with the prepared intermediate evenly to make agent B;

[0032] (3) Mix the agent A obtained in the step (1) and the agent B obtained in the step (2) uniformly to obtain the product.

Embodiment 1

[0034] This embodiment provides a purple light LED packaging glue (marked as glue 1)

[0035] First take by weighing 98.5g of bisphenol A type epoxy resin, add 0.4g optical brightening agent, 1g polyethylene glycol epoxy resin, 0.1g defoamer (high-boiling point aromatic hydroxy, ketone, ester and polydimethylsiloxane) Among them, the composition of high-boiling aromatic hydroxyl, ketone, and ester comes from the BYK special product of BYK Company (this mixture) is mixed uniformly to make A agent. Dissolve 1 g of benzyltriphenylphosphine chloride in 2 g of ethylene glycol to prepare an intermediate, then weigh 97 g of methylhexahydrophthalic anhydride, mix them uniformly with the prepared intermediate, and prepare B agent. Mix the obtained agent A and the obtained agent B evenly to obtain the purple LED encapsulating glue 1.

Embodiment 2

[0037] This embodiment provides a purple light LED packaging glue (marked as glue 2)

[0038] First take by weighing bisphenol A type epoxy resin 95g, add 4g polyethylene glycol epoxy resin wherein, 0.8g optical brightening agent, 0.2g defoamer (Jiaqian Elifom6800 is modified siloxane) and mix uniformly, Make A agent. Dissolve 1 g of benzyl triphenylphosphine chloride in 2 g of ethylene glycol to make an intermediate, then weigh 60 g of hexahydrophthalic anhydride and 37 g of methyl hexahydrophthalic anhydride, mix them with the prepared intermediate evenly, and prepare Agent B. Mix the obtained agent A and the obtained agent B evenly to obtain the glue 2 for encapsulating purple light LEDs.

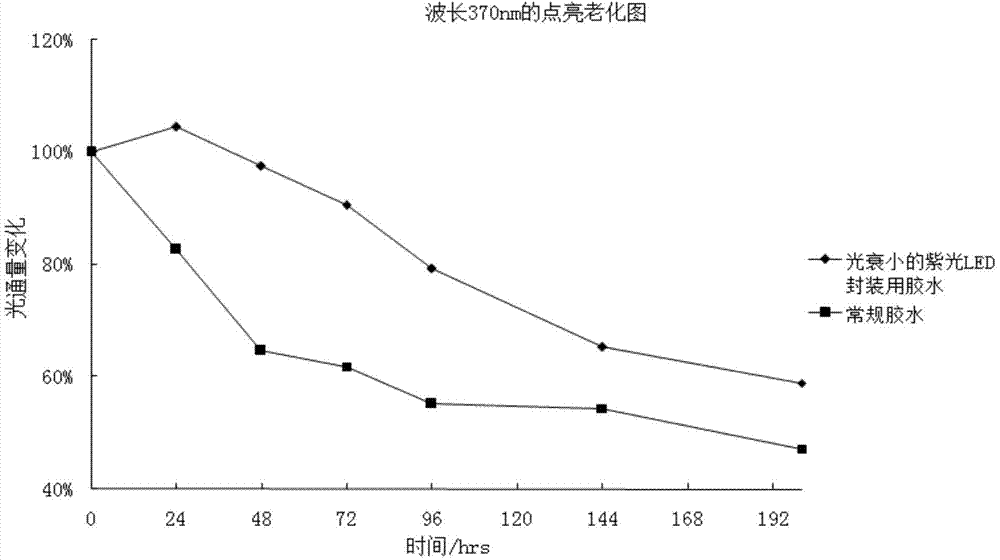

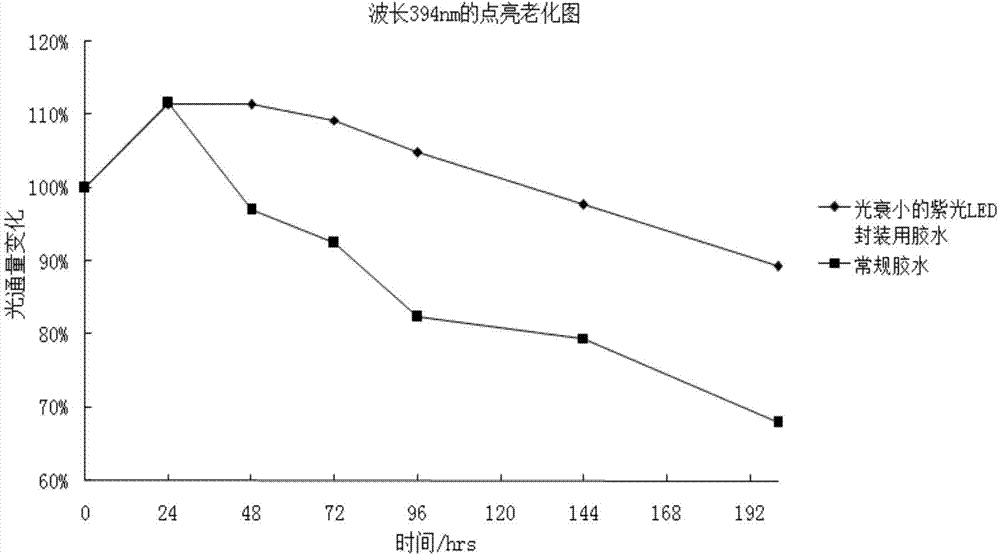

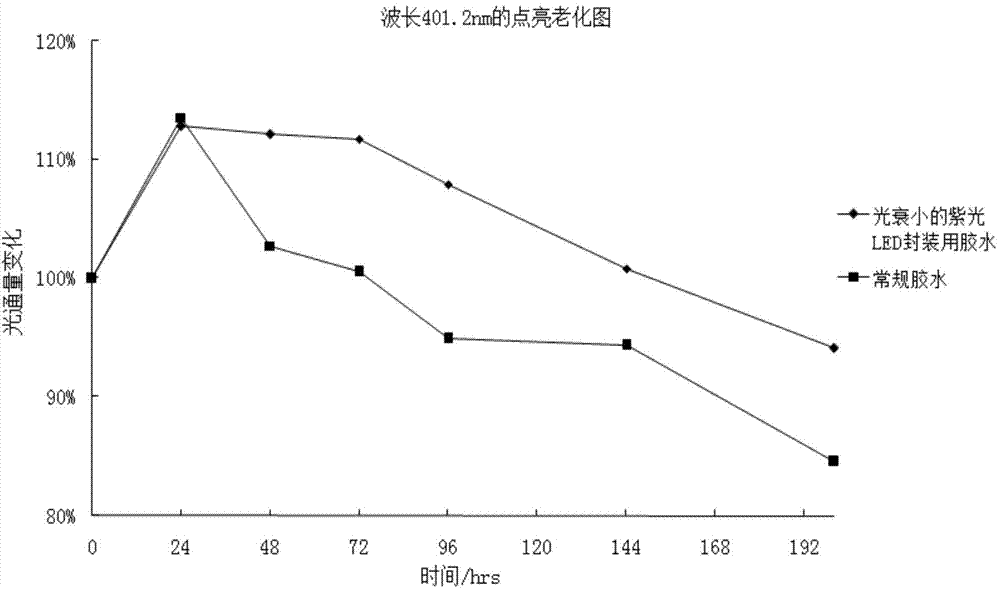

[0039] The LED lighting aging values of the purple light LED packaging glue in the embodiment of the present invention and the conventional glue at wavelengths of 370nm, 394nm and 401.2nm are shown in the following table, and see Figure 1-Figure 3 shown.

[0040]

[0041]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com