Plasma coating systems for non-planar substrates

A plasma, non-planar technology, applied in the direction of ion implantation plating, metal material coating process, device for coating liquid on the surface, etc., can solve problems such as poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

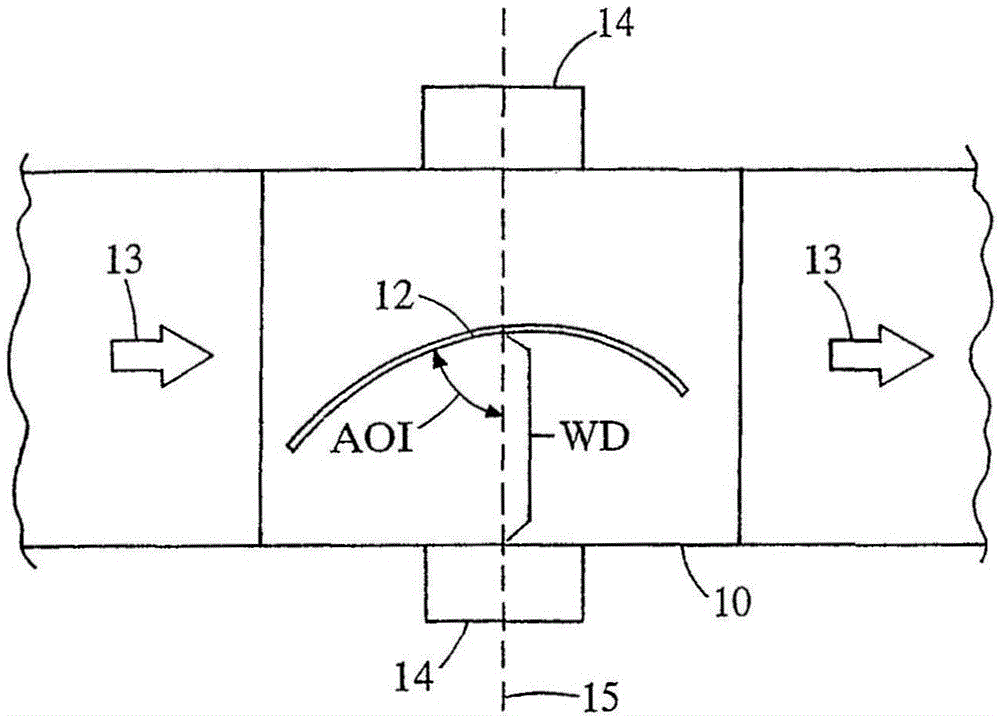

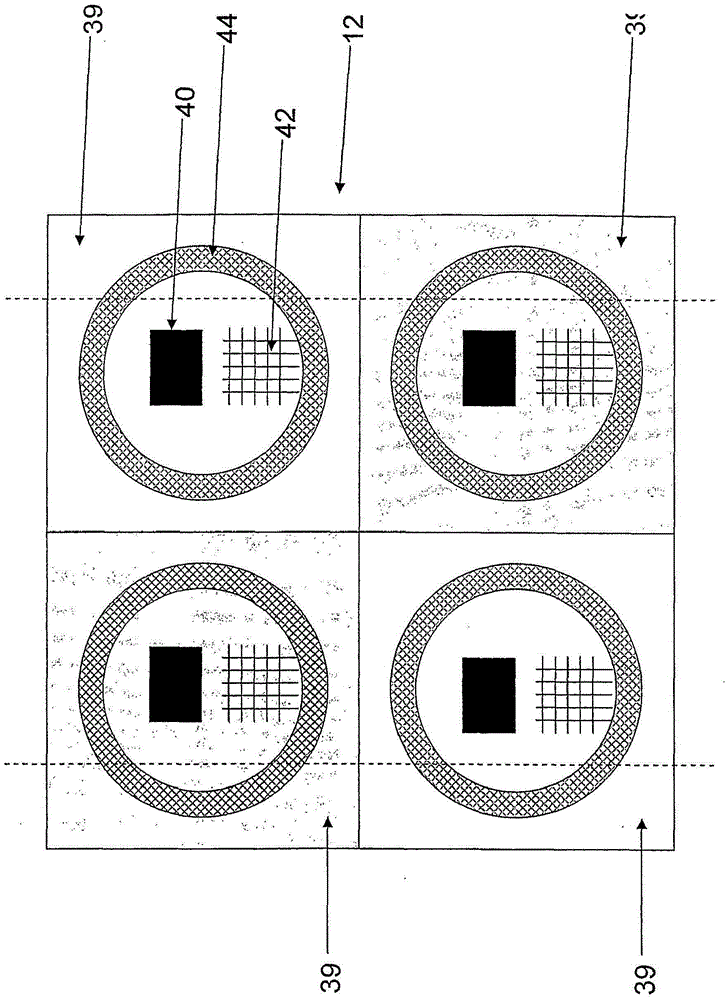

[0051] In this example, the MR10 sheets were coated with plasma polymerized and oxidized D4. During the coating process, the central lines of the two fixed ETP sources 14 are arranged parallel and separated by about 16 cm. This configuration is used to coat approximately 64in 2 Substrate. Mount four 4" x 4" sample 39 on aluminum fixtures such as figure 2 shown. Samples are indicated as 1T (top right), 1B (bottom right), 2T (top left) and 2B (bottom left). The substrate passed vertically past ETP source 14 at a scan speed of about 2.3 cm / sec. Rectangle 40 represents a typical location for a silicon chip. The coating thickness on these chips was determined by ellipsometry. During experiments in which coating thickness profiles were formed, silicon chips were placed every 1-inch along the substrate in vertical and horizontal lines. The cross-hatching 42 is at the position where the adhesion of the coating was measured before and after immersion in water at 65°C for 3 da...

Embodiment 2

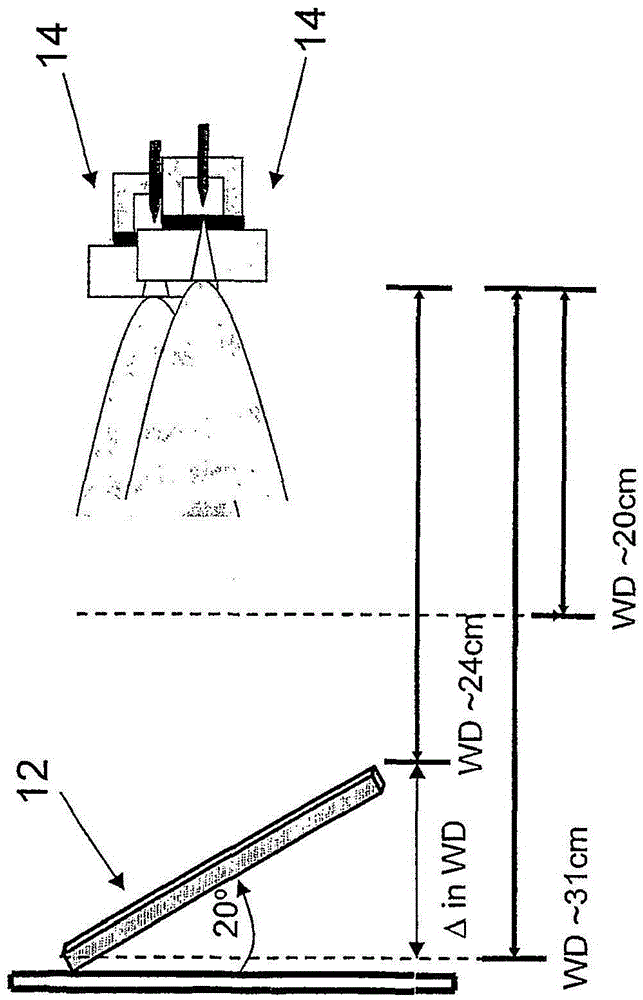

[0055] The process conditions were similar to Example 1, except that the WD was increased to 31 cm. The final coating thickness was 2.1 microns, the same as Example 1, but the average Taber delta haze was increased to about 3% and about 4% (for both runs). Therefore, obtaining the desired coating thickness does not necessarily ensure good wear resistance of the coating, especially for coatings formed at larger WD. Therefore, non-planar parts with a WD exceeding the threshold WD do not have uniform wear resistance, even though the coating thickness may be uniform.

Embodiment 3

[0057] Process condition is similar to embodiment 1, but the angle of substrate holder is about 20 degrees (such as image 3 shown) such that the WD at the top of the substrate is 31 cm and the bottom is 24 cm. A uniform coating thickness of about 2.1 microns was obtained, but the Taber delta haze increased from about 4% at the bottom (ie, shorter working distance) to 10% at the top. Thus, Comparative Examples 1-3 show that flat or angled parts coated using these process conditions have poor Taber at relatively long working distances.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com