Double-vacuum-layer composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

A sealing strip and double vacuum technology, applied in building components, thermal insulation, sound insulation, etc., can solve problems such as cold bridges and thermal insulation performance not reaching the best state, so as to avoid damage, reduce temperature, ensure thermal insulation performance and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

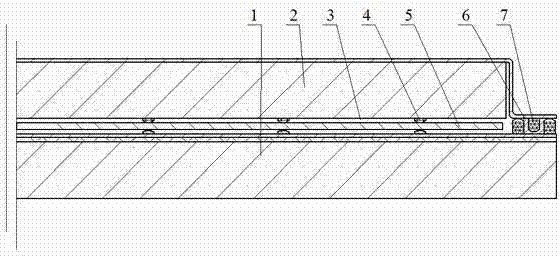

[0042] Example: see figure 1 , sealing strip edge sealing double vacuum layer composite vacuum board is composed of panel 1, core board 2, vacuum chamber 3, support 4 and partition 5, panel 1 is metal plate, ceramic plate, glass plate, plastic plate or composite plate, Preferably 3-5mm thick toughened glass plate, ceramic plate, stone plate, artificial stone plate or aluminum-plastic composite plate, etc., and paste it on the lower surface of the vacuum chamber 3 with a high-temperature adhesive. The high-temperature adhesive can be selected from room temperature or high temperature curing. Organic adhesives such as phenolic resin glue, epoxy resin glue, silicone resin glue, and polyimide, as well as commonly used inorganic adhesives or organic-inorganic composite adhesives, etc.; the core board 2 is a metal plate, ceramic plate, glass plate, plastic plate or Composite panels, preferably 3-4mm thick tempered glass panels, 1-2mm thick aluminum alloy panels or fiber composite pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com