High reliability small outline package (SOP) lead frame and production method of packaging piece

A technology for encapsulating leads and lead frames, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of high cost, low number of frame rows, low material utilization rate, etc., and meet the requirements of low cost, mass use, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

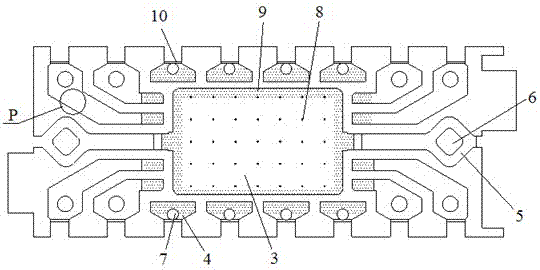

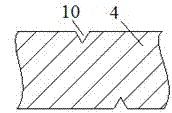

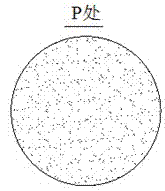

[0024]A lead frame body with a length L of 269.6±0.10 mm and a width H of 83.0±0.05 mm is manufactured. There are 240 packaging units on the lead frame body, and all the packaging units are arranged in a matrix of 12 rows and 20 columns. The packaging unit includes a carrier, the back of the carrier and along the periphery of the carrier are provided with a frame-shaped structure composed of multiple silver-plated rings, and in the frame-shaped structure, the back of the carrier is provided with a plurality of pits arranged in a square matrix; the carrier There are a plurality of inner pins on both sides, and each inner pin is respectively provided with a locking hole and a V-shaped waterproof groove, and a carrier connecting rod is respectively arranged on the other two sides of the carrier, and one end of the carrier connecting rod is connected to the The carrier is connected, and the size of the other end of the carrier connecting rod is larger than the size of the end conne...

Embodiment 2

[0026] A lead frame body with a length L of 269.6±0.10 mm and a width H of 83.0±0.05 mm is manufactured. There are 240 packaging units on the lead frame body, and all the packaging units are arranged in a matrix of 12 rows and 20 columns. The packaging unit includes a carrier, the back of the carrier and along the periphery of the carrier are provided with a frame-shaped structure composed of multiple silver-plated rings, and in the frame-shaped structure, the back of the carrier is provided with a plurality of pits arranged in a square matrix; the carrier There are a plurality of inner pins on both sides, and each inner pin is respectively provided with a locking hole and a V-shaped waterproof groove, and a carrier connecting rod is respectively arranged on the other two sides of the carrier, and one end of the carrier connecting rod is connected to the The carrier is connected, and the size of the other end of the carrier connecting rod is larger than the size of the end conn...

Embodiment 3

[0028] A lead frame body with a length L of 269.6±0.10 mm and a width H of 83.0±0.05 mm is manufactured. There are 240 packaging units on the lead frame body, and all the packaging units are arranged in a matrix of 12 rows and 20 columns. The packaging unit includes a carrier, the back of the carrier and along the periphery of the carrier are provided with a frame-shaped structure composed of multiple silver-plated rings, and in the frame-shaped structure, the back of the carrier is provided with a plurality of pits arranged in a square matrix; the carrier There are a plurality of inner pins on both sides, and each inner pin is respectively provided with a locking hole and a V-shaped waterproof groove, and a carrier connecting rod is respectively arranged on the other two sides of the carrier, and one end of the carrier connecting rod is connected to the The carrier is connected, and the size of the other end of the carrier connecting rod is larger than the size of the end conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com