Thin film transistor

A thin film transistor and protective film technology, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as characteristic degradation, and achieve the effect of excellent TFT characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Hereinafter, the present invention will be described in more detail by citing the examples, but the present invention is not limited to the following examples, and can be appropriately modified and implemented within the scope of being able to adapt to the gist of the foregoing and the following. included in the technical scope of the present invention.

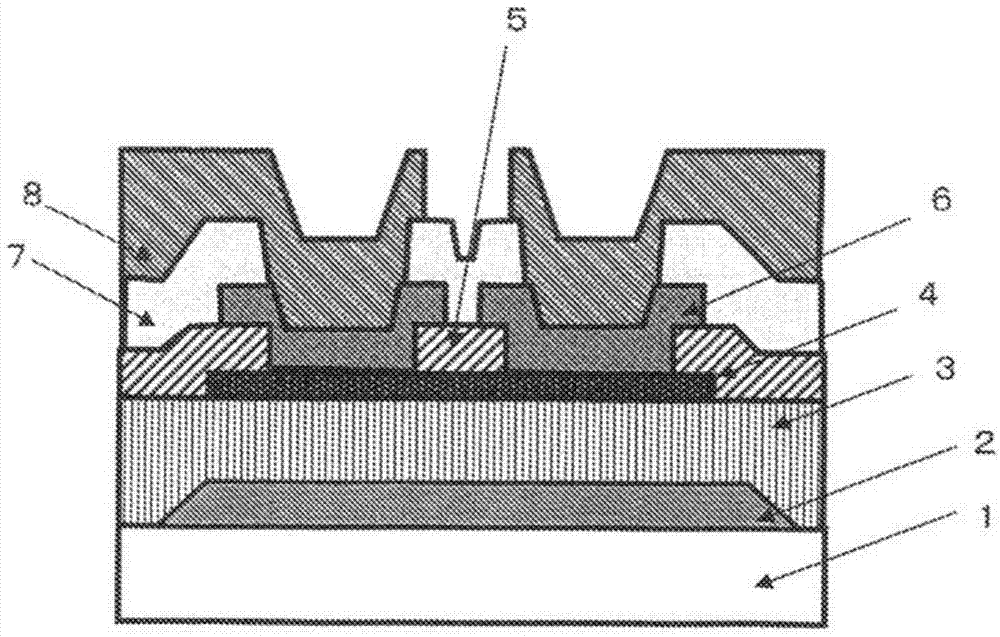

[0069] First, a Mo thin film (film thickness 100 nm) was formed on a glass substrate (EAGLE XG manufactured by Corning, diameter 100 mm×thickness 0.7 mm) as a gate electrode thin film, and patterned by a known method to obtain a gate electrode. The Mo thin film uses a pure Mo sputtering target, and is carried out by DC sputtering method under the conditions of film forming temperature: room temperature, film forming power: 300W, carrier gas: Ar, pressure: 2mTorr.

[0070] Next, as a gate insulating film, SiO 2 Film (200nm) was formed. The gate insulating film is formed by plasma CVD method in a carrier gas: SiH 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com