Wolfberry and Chinese yam powder and preparation method thereof

A preparation process and technology of yam powder, applied in the field of wolfberry yam powder and its preparation, can solve the problems of single variety, low quality, damage, etc., and achieve the effects of high biological activity, improving immunity, and enhancing memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

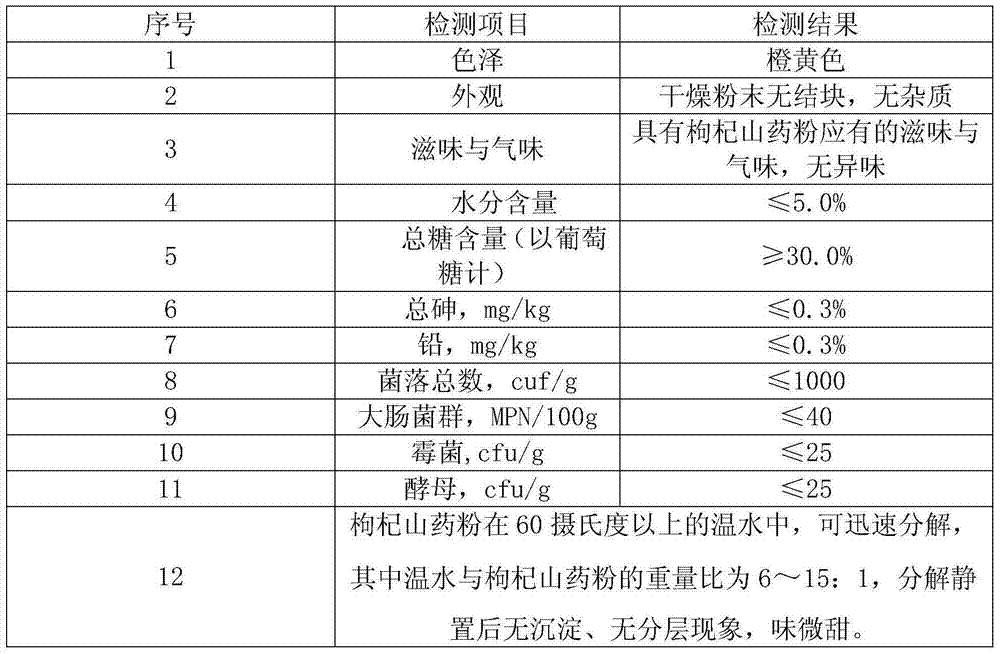

Image

Examples

Embodiment approach 1

[0033] In the first embodiment, wolfberry yam powder is obtained through the following preparation process:

[0034] The picked fresh wolfberry fruits are cleaned and sterilized, the washed fresh wolfberry fruits are quantitatively loaded in the material truck, and the washed fresh wolfberry fruits are placed in the cold storage by the material truck for quick freezing, and the temperature of the cold storage is set to -25℃~- 18℃, the quick-freezing time is 6 hours. After the quick-freezing is completed, send the quick-frozen fresh wolfberry fruit into a vacuum container with a vacuum pressure of 0.07MPa and a temperature of -50°C~-40°C for sublimation dehydration and drying for 18-25 hours. After dehydration and drying, freeze-dried wolfberry is formed;

[0035] The freeze-dried wolfberry is ultra-finely pulverized in an environment with a temperature of 10℃~15°C and a humidity of less than or equal to 30% to form a freeze-dried wolfberry powder. The color of the freeze-dried wolf...

Embodiment approach 2

[0040] The second embodiment is to clean the collected dried wolfberry fruits, and load the cleaned dried wolfberry fruits in a material truck quantitatively, and put the dried wolfberry fruits in the cold storage by the material truck for quick freezing, and the temperature in the cold storage is controlled at -25℃~-18 ℃, the quick-freezing time is 6-12 hours. After the quick-freezing is completed, place the quick-frozen dried wolfberry fruit in a vacuum container for sublimation dehydration and drying. The pressure in the vacuum container is less than or equal to 0.07MPa, and the temperature is -50℃~-40℃ , The time for sublimation dehydration and drying is 18-25 hours, and the dried wolfberry fruit after sublimation dehydration and drying forms freeze-dried wolfberry;

[0041] The freeze-dried wolfberry is ultrafinely pulverized in an environment with a temperature of 15°C to 25°C and a humidity of 30% or less to form a freeze-dried wolfberry powder. The color of the freeze-drie...

Embodiment approach 3

[0046] The third embodiment is to clean and sterilize the picked fresh wolfberry fruits. The washed fresh wolfberry fruits are quantitatively loaded into the material truck, and the washed fresh wolfberry fruits are placed in the freezer for quick freezing through the material truck. The temperature of the freezer is set to- 25℃~-18℃, the quick-freezing time is 6-12 hours. After the quick-freezing is completed, send the quick-frozen fresh wolfberry fruit into a vacuum container with a vacuum pressure of 0.07MPa and a temperature of -50℃~-40℃ for sublimation dehydration and drying After 18-25 hours, the fresh wolfberry fruit will be dehydrated and dried to form freeze-dried wolfberry;

[0047] The freeze-dried wolfberry is ultrafinely pulverized in an environment with a temperature of 15°C to 25°C and a humidity of 30% or less to form a freeze-dried wolfberry powder. The color of the freeze-dried wolfberry powder is orange-yellow, and the moisture content of the freeze-dried wolfbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com