Three dimensional biology printing device and method

A printing device, three-dimensional biological technology, applied in medical science, prosthesis, etc., can solve the problems of unreliable connection, affecting the biological activity of cells, and the existence of harmful components, and achieve the effect of improving printing accuracy, wide application range and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

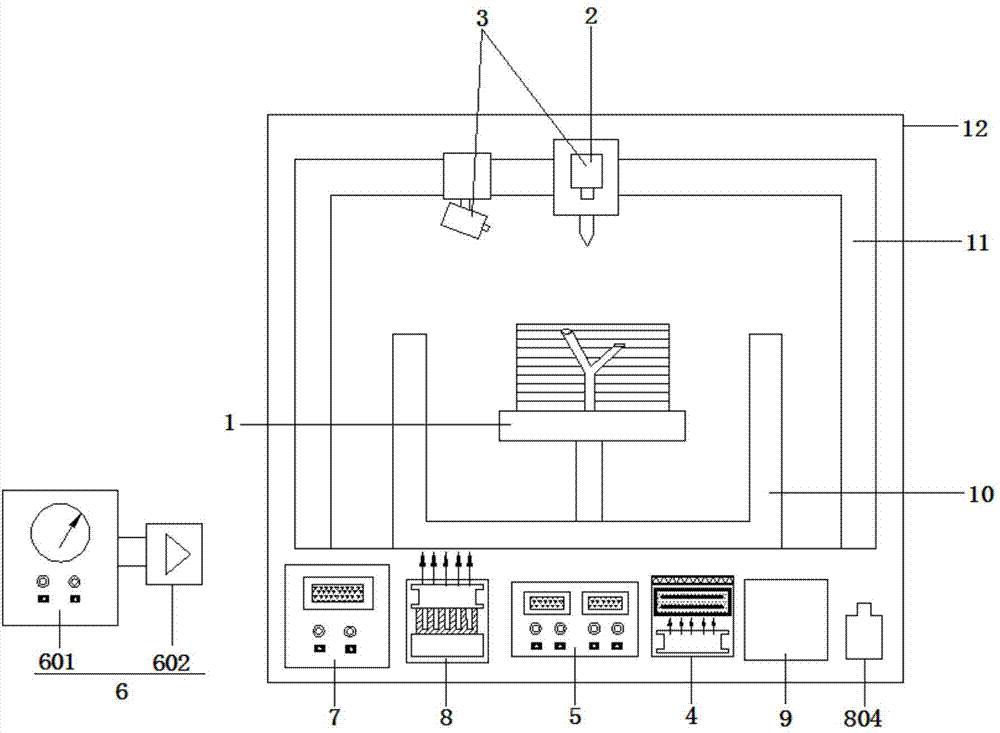

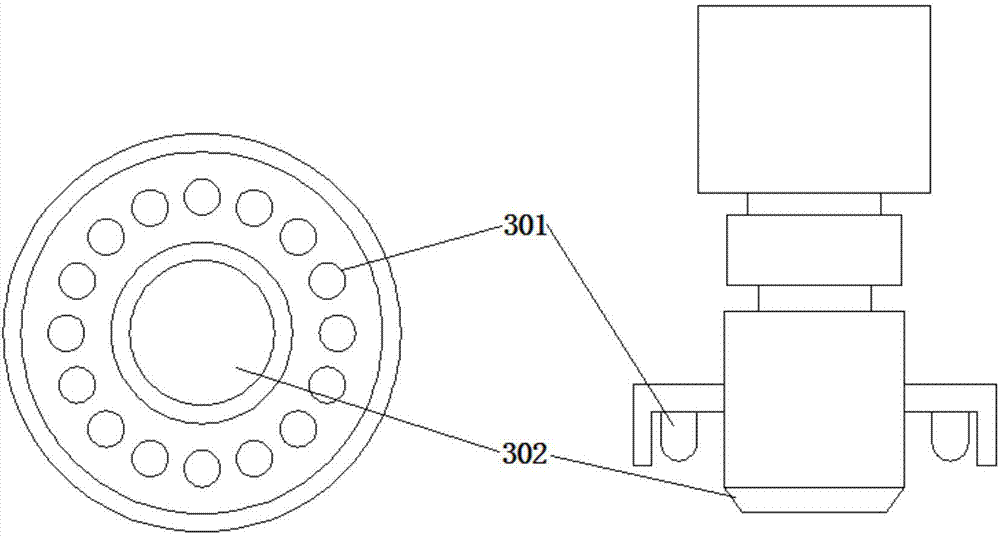

[0037] Such as figure 1As shown, the three-dimensional bioprinting device of this specific embodiment includes a printing platform 1, a nozzle 2, two CCD optical systems 3 with light sources, a plasma sterilization mechanism 4, a motion control system 5, an air pressure control mechanism 6, and a humidity regulator 7 , a temperature control unit 8, a liquid storage tank 9, an open container 10 that can hold a culture solution, a mounting frame 11, and a housing 12.

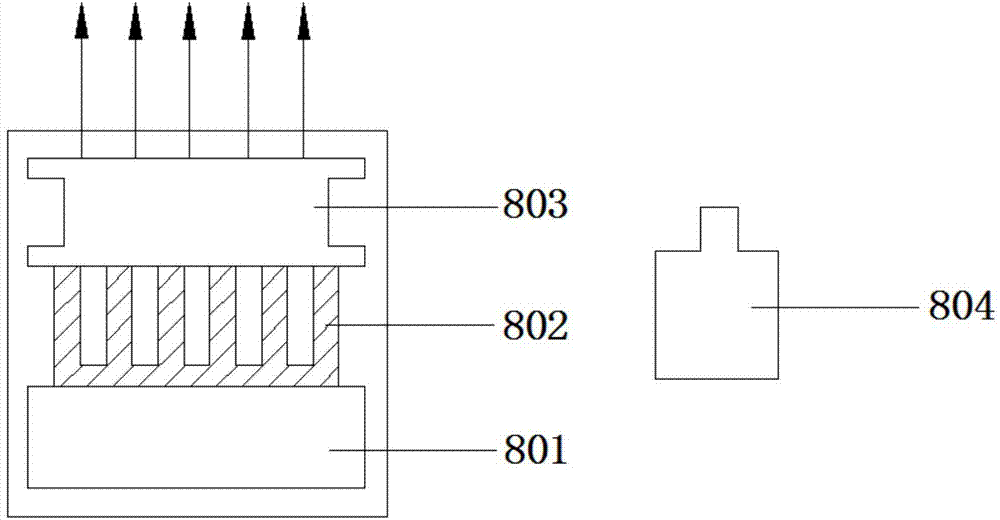

[0038] Such as figure 2 As shown, the temperature control unit 8 is composed of a heating element 801, a heat conduction element 802, an air guide module 803, and a thermal sensor 804, and the heating element 801 adopts a semiconductor heating chip. When the temperature control unit 8 is working, the heating element 801 is heated, the temperature in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com