Preparation method and shaping device of sulfur removal nozzle

A desulfurization nozzle and molding die technology, applied in ceramic molding cores, ceramic molding machines, ceramic molding mandrels, etc., can solve the problems of many curved surfaces, difficult molding, complex shapes, etc., and achieve good quality consistency, low cost, and device with simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0067] A method for preparing a low-cost desulfurization nozzle, comprising the following steps:

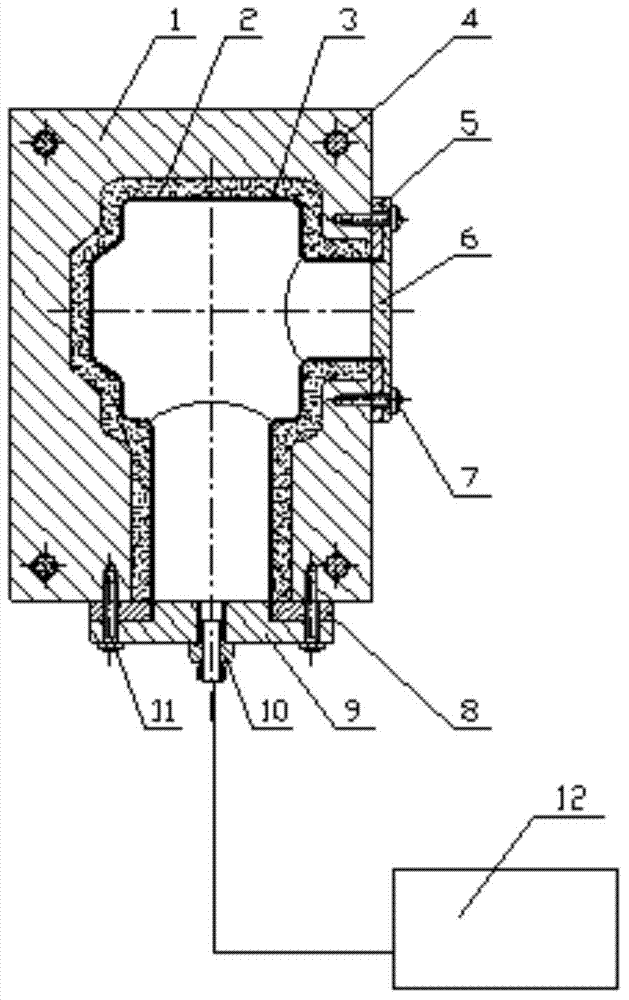

[0068] (1), first smear release agent to the inner surface of outer mold and the outer surface of inner mould, then outer mold and outer mold are affixed by clamping pin 4 to form forming mould,

[0069] (2), 50 parts of silicon carbide sand, 25 parts of modified silicon powder, 3 parts of silicon nitride powder, 1 part of aluminum oxide, 0.5 part of vanadium oxide, 0.1 part of copper powder, 0.1 part of sodium tannate, 0.1 part of humic acid Sodium is added to the ball mill, mixed according to the ratio of material: ball = 1:1.5 and ball milled for 3 hours, then passed through a 5-mesh sieve, and the ground balls are sieved to obtain the mixed powder;

[0070] (3) Install the outer mold first, then put the inner mold into the outer mold, fill the gap between the outer mold and the inner mold with the powder obtained in step (2), and install the blocking material circular plate a...

specific Embodiment 2

[0111] A method for preparing a low-cost desulfurization nozzle, comprising the following steps:

[0112] (1), first smear release agent to the inner surface of outer mold and the outer surface of inner mould, then outer mold and outer mold are affixed by clamping pin 4 to form forming mould,

[0113] (2), 75 parts of silicon carbide sand, 40 parts of modified silicon powder, 8 parts of silicon nitride powder, 5 parts of alumina, 2 parts of vanadium oxide, 1 part of copper powder, 0.3 parts of sodium tannate, 0.3 parts of humic acid Sodium is added to the ball mill, mixed according to the ratio of material: ball = 1:2, ball milled for 3 hours, passed through a 5-mesh sieve, and sieved to remove the grinding balls to obtain the mixed powder;

[0114] (3) Install the outer mold first, then put the inner mold into the outer mold, fill the gap between the outer mold and the inner mold with the powder obtained in step (2), and install the blocking material circular plate and cover ...

specific Embodiment 3

[0153] A method for preparing a low-cost desulfurization nozzle, comprising the following steps:

[0154] (1), first smear release agent to the inner surface of outer mold and the outer surface of inner mould, then outer mold and outer mold are affixed by clamping pin 4 to form forming mould,

[0155] (2), 60 parts of silicon carbide sand, 30 parts of modified silicon powder, 5 parts of silicon nitride powder, 3 parts of aluminum oxide, 1 part of vanadium oxide, 0.5 part of copper powder, 0.2 part of sodium tannate, 0.2 part of humic acid Sodium is added to the ball mill, mixed according to the ratio of material: ball = 1:1.8 and ball milled for 3 hours, then passed through a 5-mesh sieve, and the ground balls are sieved to obtain the mixed powder;

[0156] (3) Install the outer mold first, then put the inner mold into the outer mold, fill the gap between the outer mold and the inner mold with the powder obtained in step (2), and install the blocking material circular plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com