Magnesium alloy corrosion-resistant coating and application thereof

A technology for magnesium alloys and coatings, applied in anti-corrosion coatings, metal material coating processes, coatings, etc., can solve the problems that cannot well solve the anti-corrosion and service performance requirements of magnesium alloys, affect the application range of magnesium alloys, etc., and achieve The preparation process is simple and feasible, the repeatability is strong, the effect of high hardness and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

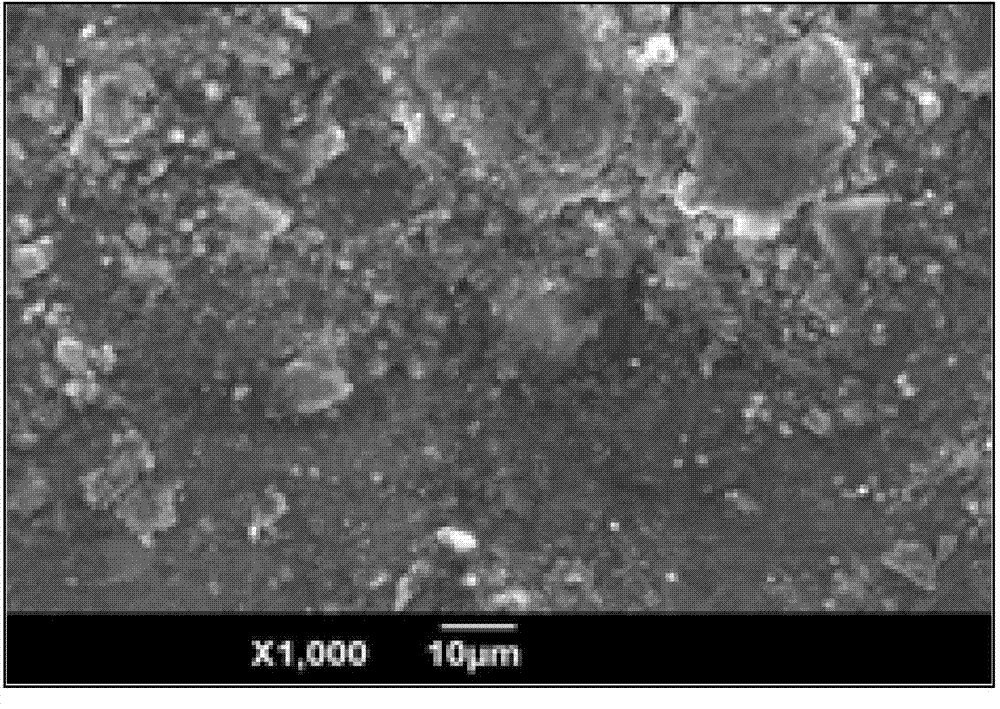

[0039] The present embodiment magnesium alloy corrosion-resistant coating is made of zinc powder, aluminum powder, zirconia, yttrium oxide, yttrium nitrate, polyethylene glycol, sodium molybdate, hydroxymethyl cellulose, silane coupling agent KH-560, diphenyl Dimethoxysilane and deionized water are uniformly mixed, wherein the mass percentage of zinc powder is 18%, the mass percentage of aluminum powder is 5%, the mass percentage of zirconia is 8%, and the mass percentage of yttrium oxide is 0.7%. , the mass percentage of yttrium nitrate is 3%, the mass percentage of polyethylene glycol is 16%, the mass percentage of sodium molybdate is 5%, the mass percentage of hydroxymethyl cellulose is 0.8%, the silane coupling agent KH-560 The mass percent of diphenyldimethoxysilane is 3%, the mass percent of diphenyldimethoxysilane is 4%, and the balance is deionized water; the zinc powder and aluminum powder are circular flake powders, and the sheet diameter of the zinc powder is 10-20 ...

Embodiment 2

[0054] The present embodiment magnesium alloy anticorrosion coating is made of zinc powder, aluminum powder, zirconia, yttrium oxide, yttrium nitrate, polyethylene glycol, sodium molybdate, hydroxymethyl cellulose, silane coupling agent KH-560, diphenyl Dimethoxysilane and deionized water are uniformly mixed, wherein the mass percentage of zinc powder is 16%, the mass percentage of aluminum powder is 4%, the mass percentage of zirconia is 5%, and the mass percentage of yttrium oxide is 0.8%. , the mass percentage of yttrium nitrate is 4%, the mass percentage of polyethylene glycol is 15%, the mass percentage of sodium molybdate is 3%, the mass percentage of hydroxymethyl cellulose is 0.6%, the silane coupling agent KH-560 The mass percent of diphenyldimethoxysilane is 5%, the mass percent of diphenyldimethoxysilane is 3%, and the balance is deionized water; the zinc powder and aluminum powder are circular flake powders, and the sheet diameter of the zinc powder is 10-20 μm and...

Embodiment 3

[0066] The present embodiment magnesium alloy anticorrosion coating is made of zinc powder, aluminum powder, zirconia, yttrium oxide, yttrium nitrate, polyethylene glycol, sodium molybdate, hydroxymethyl cellulose, silane coupling agent KH-560, diphenyl Dimethoxysilane and deionized water are uniformly mixed, wherein the mass percentage of zinc powder is 20%, the mass percentage of aluminum powder is 6%, the mass percentage of zirconia is 10%, and the mass percentage of yttrium oxide is 0.5%. , the mass percentage of yttrium nitrate is 1%, the mass percentage of polyethylene glycol is 20%, the mass percentage of sodium molybdate is 6%, the mass percentage of hydroxymethyl cellulose is 0.9%, the silane coupling agent KH-560 The mass percent of diphenyldimethoxysilane is 2%, the mass percent of diphenyldimethoxysilane is 6%, and the balance is deionized water; the zinc powder and aluminum powder are circular flake powders, and the sheet diameter of the zinc powder is 10-20 μm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com