A high-sensitivity micro-vibration detection method

A detection method and high-sensitivity technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of difficult detection of small electrical signals and low sensitivity of micro-detection, avoid detection difficulties, and facilitate system integration. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

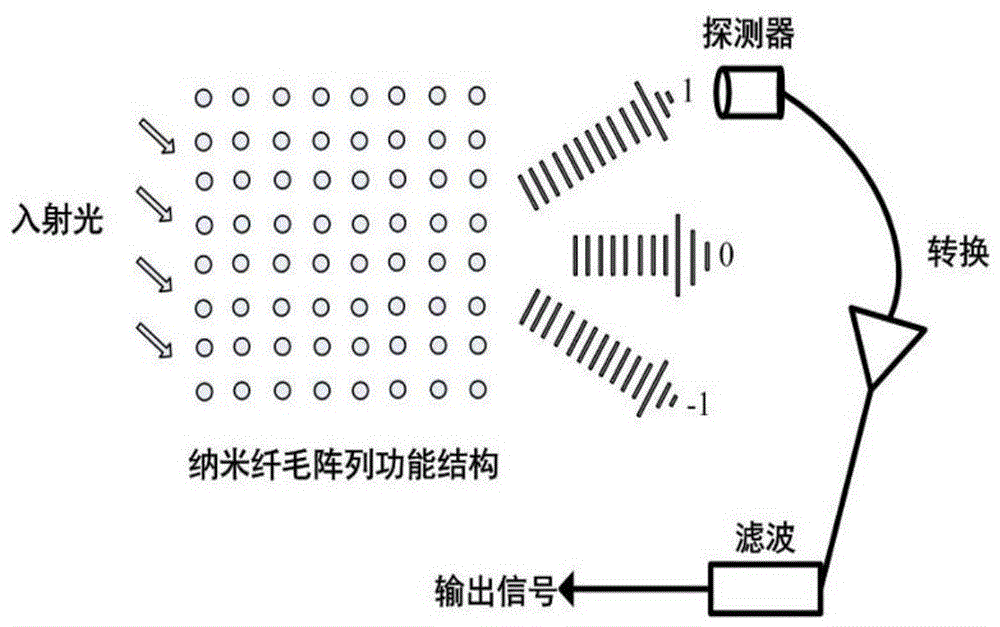

[0021] In this embodiment, a high aspect ratio nano-column array composed of 5 rows and 5 columns is provided to realize the light diffraction detection method for low-frequency sound detection, which specifically includes the following steps:

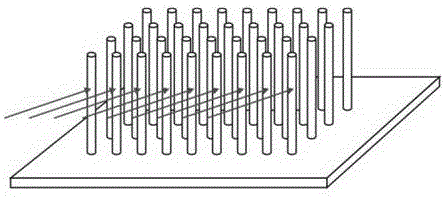

[0022] Step 1: On the silicon substrate, use photoresist as a mask to etch silicon with high-density plasma etching technology to form high-aspect-ratio nanopillars with a period of 2 microns, a diameter d of 500 nanometers, and a height h of 200 microns array.

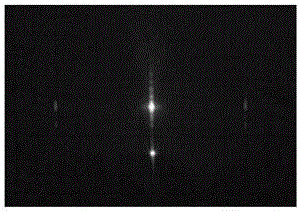

[0023] Step 2: Select a red laser with a wavelength of 520 nm, and control the beam diameter to about 50 μm through various components such as an aperture. The laser beam is incident on one side of the high-aspect-ratio nanoarray at an angle of 45°, forming light and dark diffraction fringes on the other side.

[0024] Step 3: When no external sound pressure change is felt, the diffraction fringes of the high aspect ratio nano-column array vibrate regularly. When the externa...

Embodiment 2

[0028] In this embodiment, a light diffraction detection method for realizing acceleration by a high-aspect-ratio nano-column array composed of 3 rows and 3 columns is given, which specifically includes the following steps:

[0029] Step 1: On the silicon substrate, use photoresist as a mask to etch silicon with high-density plasma etching technology to form high aspect ratio nanopillars with a period of 1 micron, a diameter d of 300 nanometers, and a height h of 200 microns array.

[0030] Step 2: Select a red laser with a wavelength of 520 nm, and control the beam diameter to about 50 μm through various components such as an aperture. The laser beam is incident on one side of the high-aspect-ratio nanoarray at an angle of 45°, forming light and dark diffraction fringes on the other side.

[0031] Step 3: The device is moved with an acceleration of a, and the high aspect ratio nano-array is shifted under the action of the acceleration, causing the diffraction fringes to chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com