Linear variable-area wave zone plate with feature of long focal length

A zone plate and variable area technology, applied in the field of long focal depth optical components, can solve problems such as inapplicability, and achieve the effect of easy processing and high lateral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

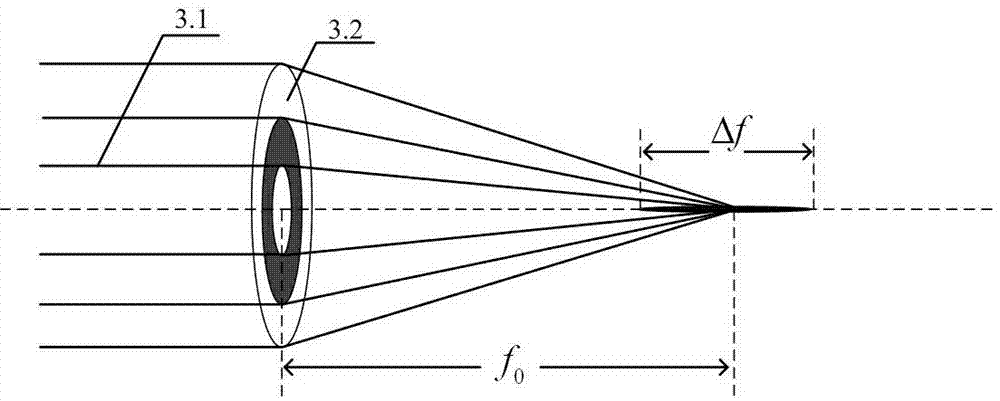

[0038] This embodiment discloses a linear variable area zone plate with long focal depth suitable for the visible light band, and gives the design method of the zone plate layout, the working mode and diffraction characteristics of the zone plate, and the preparation method of the zone plate .

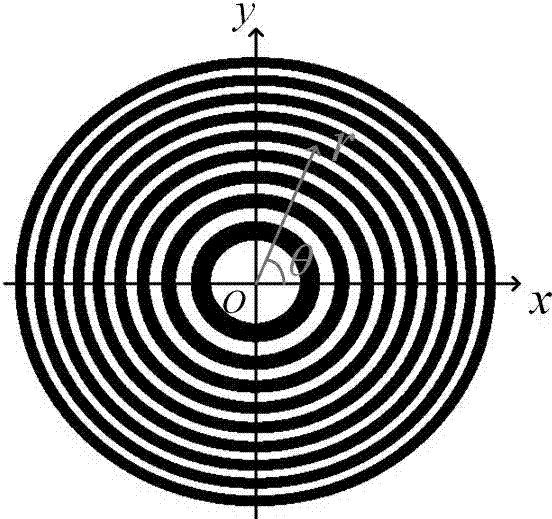

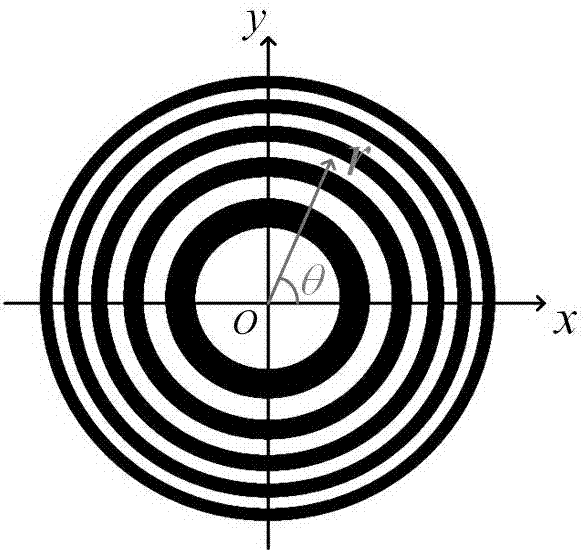

[0039] 1. Design method of zone plate layout

[0040] Zone plate in ( )with The structure under the coordinate system is as follows Figure 1a with Figure 1b As shown, the variables in the two coordinate systems satisfy the conversion relationship: . in Under the coordinate system, the structure of the linear variable area zone plate of the present invention is as Figure 1b As shown, it is a quasi-period structure, and each period corresponds to a ring zone of the zone plate, the period And zone area Satisfaction relationship: . There is a linear change between adjacent cycles And satisfied , That is, the area between the corresponding adjacent loops changes linearl...

Embodiment 2

[0056] Preparation of X-ray lithography replication zone plate

[0057] a: Same as step c in the preparation method of Example 1;

[0058] b: Use the mask produced in embodiment 1 as the original exposure image, and perform X-ray exposure on the film produced in step a of this embodiment;

[0059] c: Same as step e of the preparation method in Example 1;

[0060] d: The photoresist is removed to obtain a replication zone plate of a linear variable area zone plate with long focal depth characteristics.

Embodiment 3

[0062] Preparation of anti-wave zone plates

[0063] a: By means of transfer, using the same silicon wafer, gold film and photoresist materials as in Example 1 or Example 2, a light-transmitting substrate is added under the gold film as a support. The reverse pattern structure of the second embodiment can be used to make the anti-wave zone plate of the linear variable area zone plate with long focal depth. The diffraction pattern of the anti-wave zone plate is the same as that of the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com