Preparation method and application of a high energy density lithium-sulfur battery electrode

A high-energy density, lithium-sulfur battery technology, applied in battery electrodes, electrode manufacturing, lithium batteries, etc., can solve the problem of poor conductivity of electrode materials, and achieve the effect of improving conductivity, energy density, and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The three-dimensional flexible high-conductivity carbon fiber network is a three-dimensional carbon current collector with high flexibility and excellent conductivity after high-temperature carbonization. The three-dimensional conductive carbon fiber network is prepared by heat treatment of absorbent cotton at a high temperature of 800 to 1200 ℃ (see patent: application number 201510069412.5 , A method for preparing flexible and highly conductive three-dimensional interconnected hollow carbon fiber), which exhibits excellent flexibility and good conductivity. The method uses long-fiber cellulose filaments (absorbent cotton) as raw materials to carbonize and crystallize the material through high-temperature treatment to obtain a volume-controllable, hollow, highly conductive, and flexible carbon fiber network structure. The diameter of the hollow carbon fiber is 1-100. Micron, the inner diameter is 0.5-90 microns, the specific steps are as follows:

[0035] (1) Take the lon...

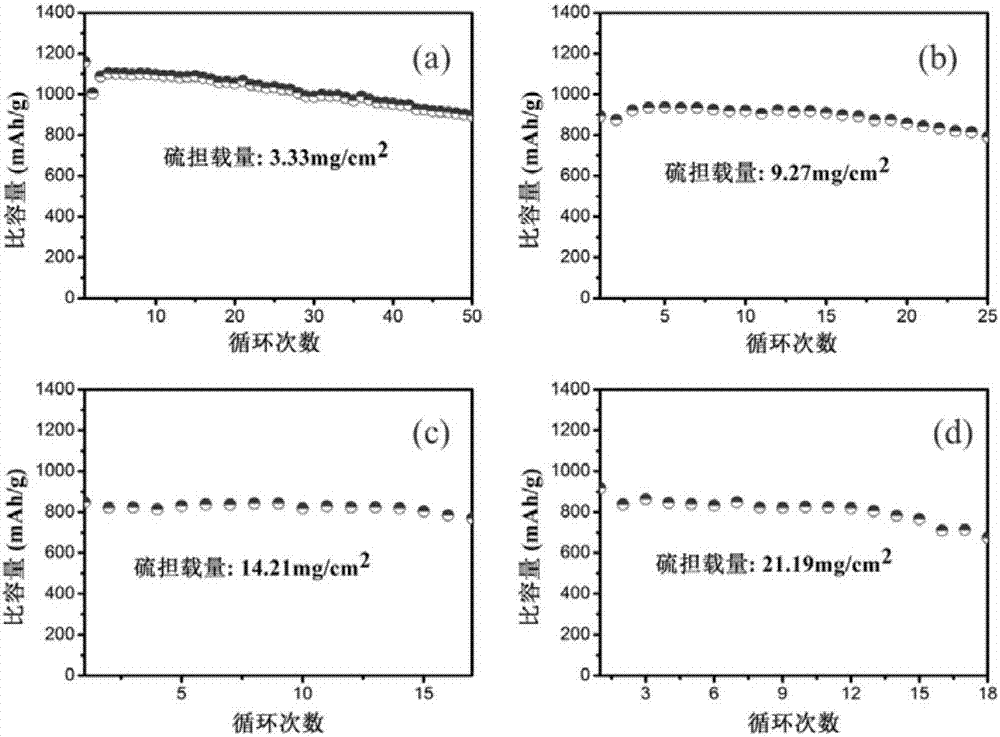

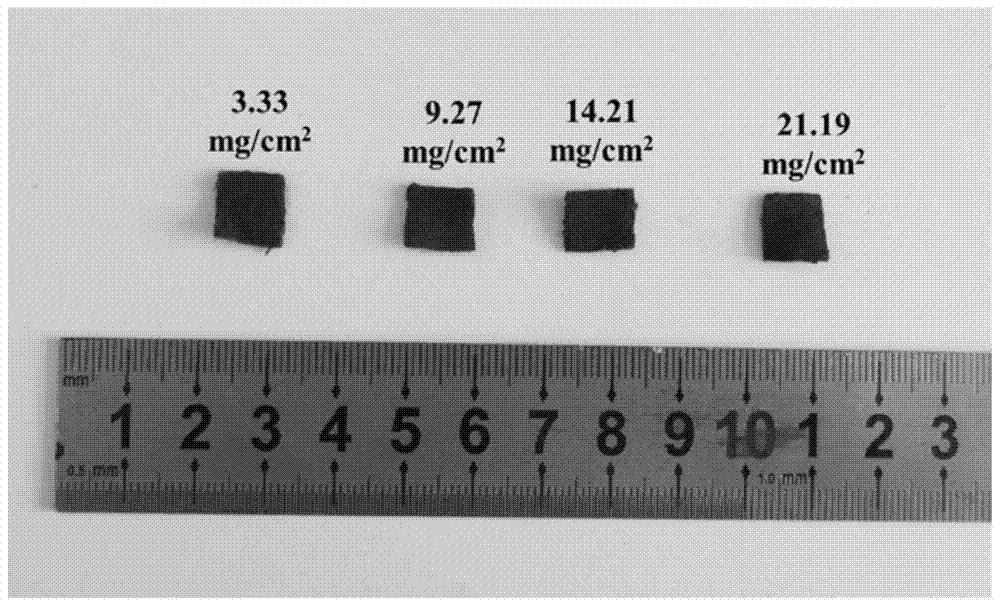

Embodiment 1

[0046] Preparation of conductive carbon black sulfur slurry

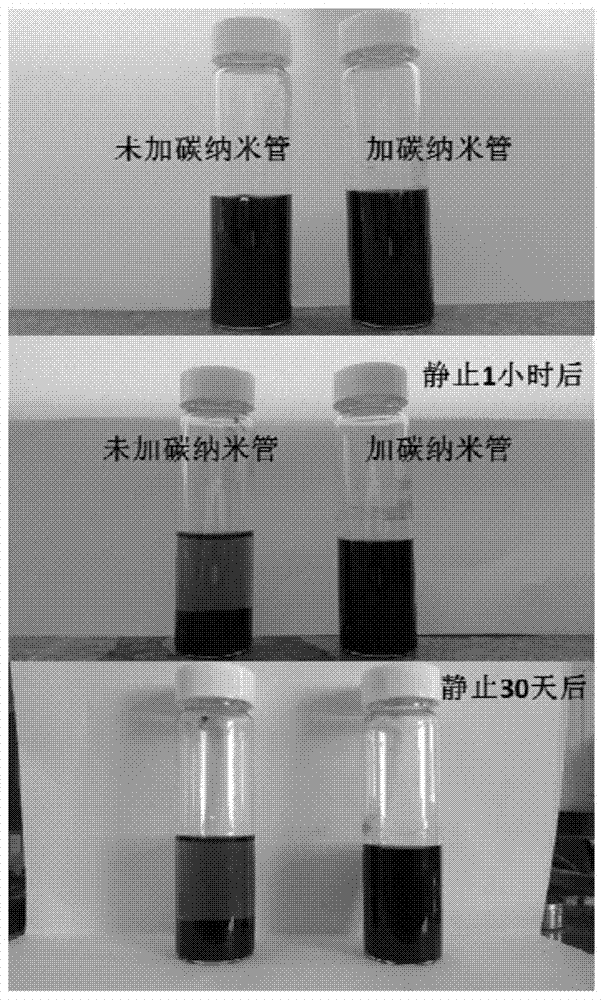

[0047] Take sublimed sulfur powder and conductive carbon black (mass ratio 9:1), a total of 2g, and add 45ml of N-methylpyrrolidone (NMP). Disperse in the cell ultrasonic pulverizer, the power is 90w, after 30 minutes of ultrasonic, a uniform black dispersion (such as figure 1 , The left sample).

Embodiment 2

[0049] Take sublimed sulfur powder, acidified multi-walled carbon nanotubes and conductive carbon black (mass ratio 9:0.5:0.5), a total of 2g, add 45ml of N-methylpyrrolidone (NMP), and disperse in a cell ultrasonic pulverizer. Under the power of 90w, after 30 minutes of ultrasound, a uniform black dispersion (such as figure 1 , The right sample).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com