Preparation method of titanium dioxide/iron oxide composite negative electrode material

A technology of titanium dioxide and negative electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of no lithium-ion battery patent reports, unfavorable large-scale production, cumbersome steps, etc., and achieve low price, short cycle, and process route simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

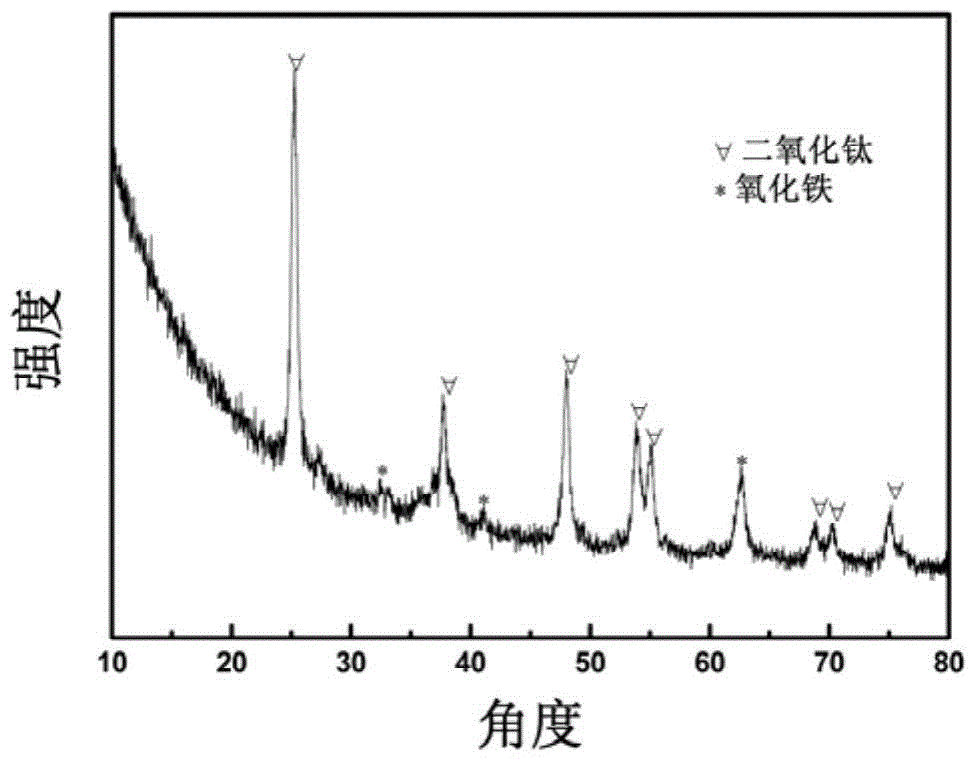

[0036] Embodiment 1, a kind of preparation method of titanium dioxide / iron oxide composite negative electrode material, carries out following steps successively:

[0037] 1), weigh 0.36 grams (1.39×10 -3 mol) titanyl sulfate, dissolved in 2 milliliters of deionized water (0.11mol), then added 0.37 grams (1.37 × 10 -3 mol) ferric chloride, stir to form an orange-yellow solution;

[0038] 2), add 0.25 grams of polyvinylpyrrolidone to the solution obtained in step 1) and stir until it is completely dissolved;

[0039] 3) Under the condition of vigorous stirring, slowly add 0.5 ml of formamide dropwise to the solution obtained in step 2) (that is, drop it in about half a minute), and after stirring for 5 minutes, age the gel at 60°C for 3 hours;

[0040] 4), drying the gel obtained in step 3) at 60°C under normal pressure for 24 hours to obtain a precursor product;

[0041] 5) The temperature of the obtained precursor product was raised to 600° C. for 5 hours in an air atmosphe...

Embodiment 2

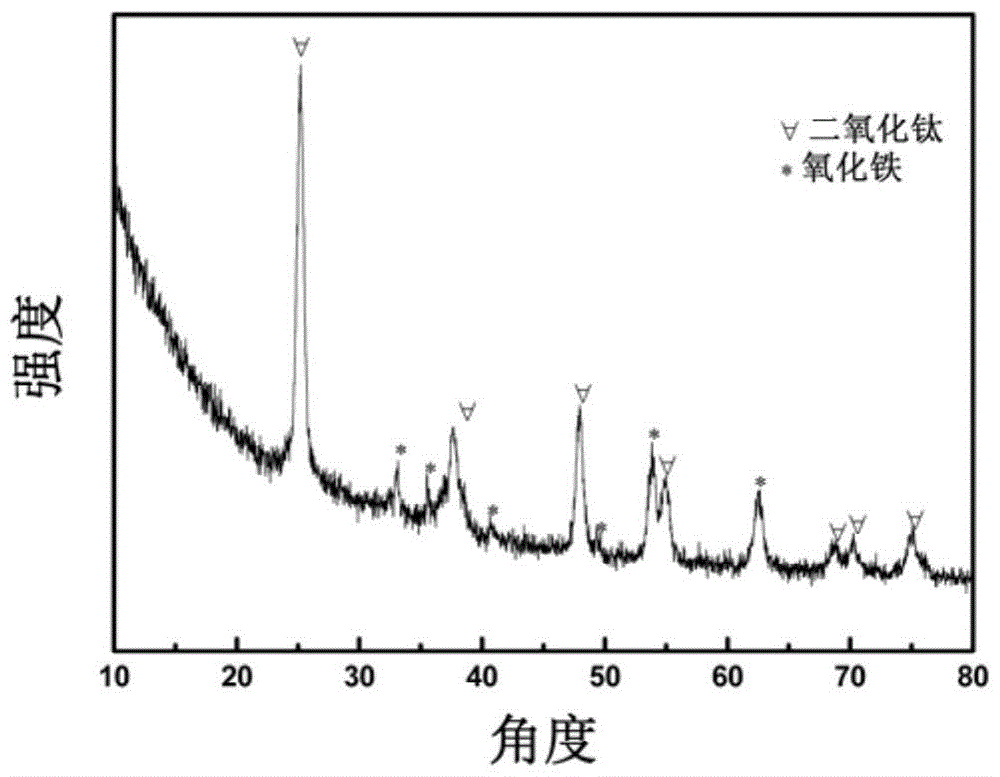

[0043] Embodiment 2, a kind of preparation method of titanium dioxide / iron oxide composite negative electrode material, carries out following steps successively:

[0044] 1), weigh 0.36 grams (1.39×10 -3 mol) titanyl sulfate, dissolved in 2 milliliters (0.11mol) of deionized water, and then added 0.5 grams (1.85×10 -3 mol) high ferric chloride, stir to form an orange-yellow solution;

[0045] 2), add 0.25 g of polyvinylpyrrolidone to the solution obtained in step 1) and stir until it is completely dissolved,

[0046] 3) Under the condition of vigorous stirring, slowly add 0.5 ml of formamide dropwise to the solution obtained in step 2) (dropping is completed in about half a minute), and after stirring for 5 minutes, age the gel at 60°C for 3 hours;

[0047] 4), drying the gel obtained in step 3) at 60°C under normal pressure for 24 hours to obtain a precursor product;

[0048] 5) The temperature of the obtained precursor product was raised to 600° C. for 5 hours in an air a...

Embodiment 3

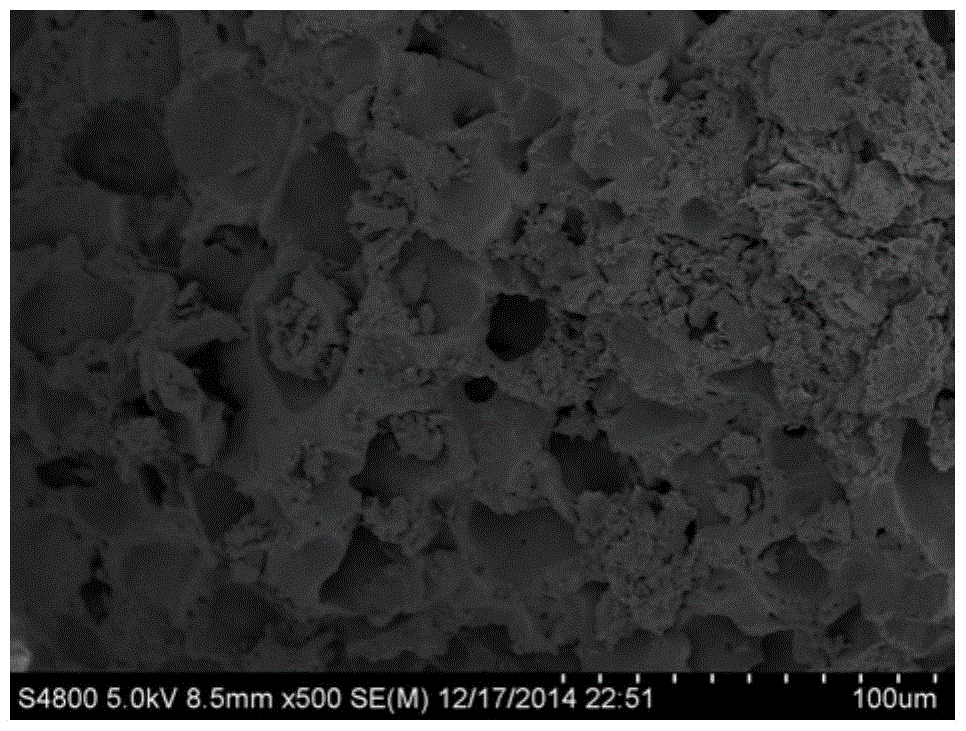

[0050] Embodiment 3, a kind of preparation method of titanium dioxide / iron oxide composite negative electrode material, carry out following steps successively:

[0051] 1), weigh 0.7 grams (2.71×10 -3 mol) titanyl sulfate, dissolved in 4 milliliters (0.22mol) of deionized water, and then added 0.37 grams (1.37×10 -3 mol) high ferric chloride, stir to form an orange-yellow solution;

[0052] 2), add 0.25 grams of polyvinylpyrrolidone to the solution obtained in step 1) and stir until it is completely dissolved;

[0053] 3) Slowly add 0.5 ml of formamide dropwise to the solution obtained in step 2) under vigorous stirring (about half a minute to finish), stir for 5 minutes and then age the gel at 60°C for 3 hours;

[0054] 4), drying the gel obtained in step 3) at 60°C under normal pressure for 24 hours to obtain a precursor product;

[0055] 5) The temperature of the obtained precursor product was raised to 600° C. for 5 hours in an air atmosphere, and then cooled to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com