Current collection layer structure of solid oxide fuel cell

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell components and other directions, can solve the problems of current collector layer pulverization, battery performance degradation, battery performance degradation, etc. The thermal expansion coefficient does not match, the solution is expensive, and the preparation cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

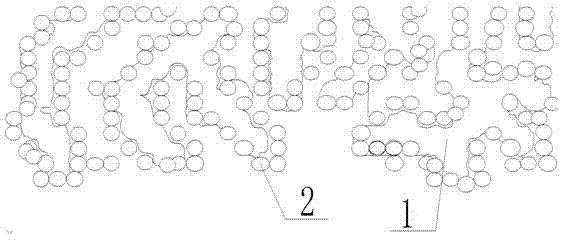

[0017] in such as figure 1 In the first embodiment shown, a solid oxide fuel cell current collecting layer structure includes a current collecting layer skeleton structure 1 and a current collecting layer active structure 2, and the current collecting layer active structure 2 is impregnated in the current collecting layer skeleton structure 1 The interior, instead of being directly attached to the battery, can effectively avoid the problem of thermal expansion coefficient mismatch between the current collector material and the battery. The active structure 2 of the current collector layer is composed of nanoparticles with high conductivity, and effective communication between the particles is formed without affecting Gas diffusion, the thickness of the current collector skeleton structure 1 is 10-100 microns, the porosity is 20-80%, and the pore size is 2-20 microns, which has good thermal expansion matching and chemical compatibility with the battery, and can be used High-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com