Functional dressing and preparation method thereof

A technology of functional and auxiliary materials, which is applied in the field of preparation of functional dressing products, can solve the problems of antibacterial, liquid absorption, anti-inflammatory and other unsatisfactory performances, and achieve the prevention of wound wound area fluid, good biocompatibility, and easy peeling The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

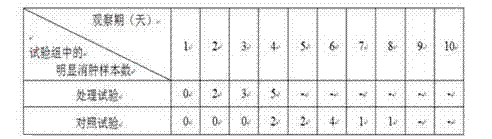

Examples

Embodiment 1

[0027] Weigh 10g of sodium alginate, 5g of glycerin, add 100mL of deionized water, stir to obtain a uniform viscous liquid, then squeeze and filter through a 100-mesh nylon mesh to obtain glue A; take another 3g of ethyl chitosan, add water 100 mL, 2 g of lactic acid was stirred and dissolved, and after adding 0.2 of Aina sesame oil, stirred, squeezed and filtered through a 100-mesh nylon mesh to obtain glue B. Stir and mix glue A and glue B evenly, vacuumize and defoam, then extrude with an extruder, coat on a stainless steel belt or on the surface of a fabric, dry with hot air at 60°C to obtain an antibacterial and healing-promoting gel film, or It is coated on the surface of the non-woven fabric first and then dried with hot air at 60°C to obtain a dressing film with better strength.

Embodiment 2

[0029] Weigh 10 g of gelatin, 6 g of glycerin, add 100 mL of deionized water, stir to obtain a uniform viscous liquid; squeeze and filter through a 100-mesh nylon mesh to obtain glue A. Take another 3g of chitosan, add 50 mL of water, 1g of lactic acid and stir to dissolve, add 0.5g of Aina sesame oil and stir, then filter as above to obtain glue B. Mix glue A and glue B evenly, adjust the pH value to 5-7 with triethanolamine, vacuumize and defoam, then extrude with an extruder, coat on a stainless steel belt or attach to the fabric surface, and dry with hot air at 60°C An antibacterial gel film for promoting healing can be obtained, or a dressing film can be obtained by first attaching it to a non-woven fabric surface and then drying it with hot air at 60°C.

[0030] The film obtained by the above method is sliced, and then laminated with a film backing with certain moisture permeability, air permeability and adhesive force to form a dressing for nursing and treatment of ...

Embodiment 3

[0032] Weigh 8 g of gelatin and 6 g of glycerin, add 100 mL of deionized water, stir to obtain a uniform viscous liquid; extrude and filter through a 100-mesh nylon mesh to obtain glue A. Take another 3 g of chitosan, add 50 mL of water, 1 g of lactic acid and stir to dissolve, add 0.7 g of Aina sesame oil and stir, then filter to obtain glue B as above; mix glue A and glue B evenly, and use triethanolamine Adjust the pH value to 5-7, vacuumize and defoam, fill it in an aluminum-plastic tube for later use, squeeze it out and apply it to the wound surface when in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com