Method for preparing orthopaedic implants

An orthopaedic implant and mixture technology, applied in the field of orthopaedic implant preparation, can solve the problems that traditional processing technology cannot meet the rapidly growing demand, difficult to automate mass production, low utilization rate of raw materials, etc., and achieve excellent biocompatibility and mechanical properties, high utilization rate of raw materials, and the effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

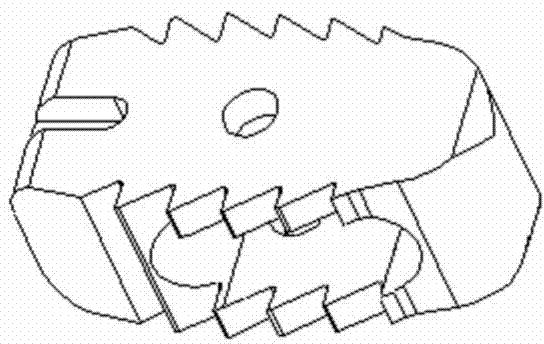

[0024] A preparation method of the orthopedic implant of the present invention, the orthopedic implant can be used for the spine, the method comprises the following steps:

[0025] (1) Feed preparation: the raw material powder is 316L stainless steel powder with an average particle size of 22 μm, the binder is composed of 37% polypropylene, 25% vegetable oil and 38% paraffin (by mass percentage), and the 316L stainless steel The powder and the binder are mixed at a mass ratio of 92:8, and the resulting mixture is put into a kneader, kneaded at 180° C. for 1 hour, crushed and granulated after cooling to obtain granular feed.

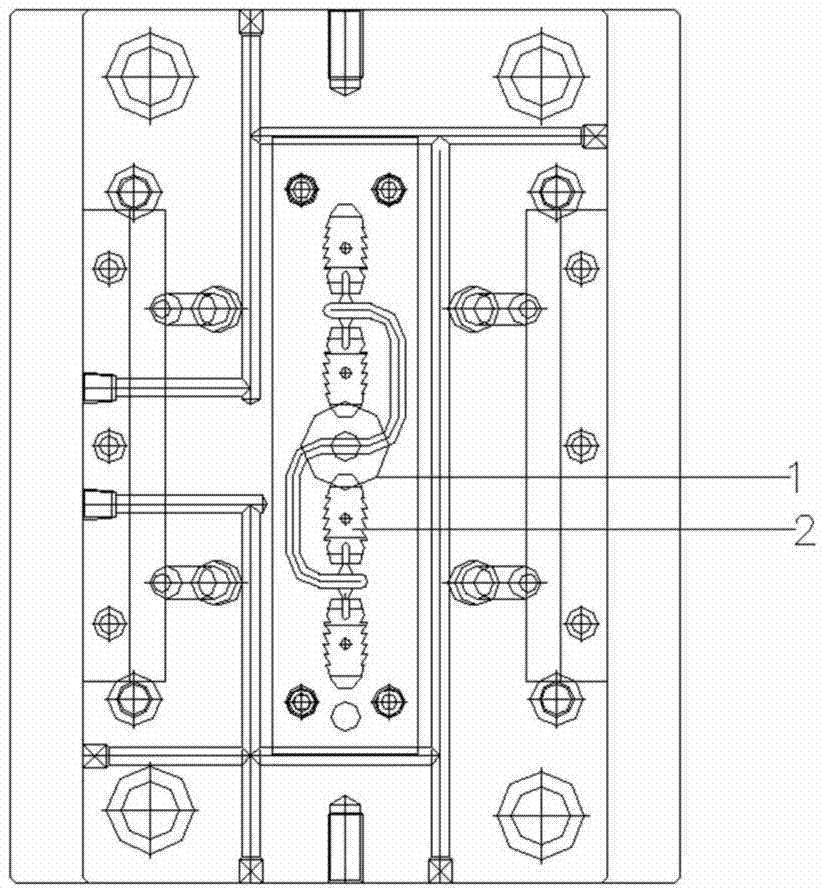

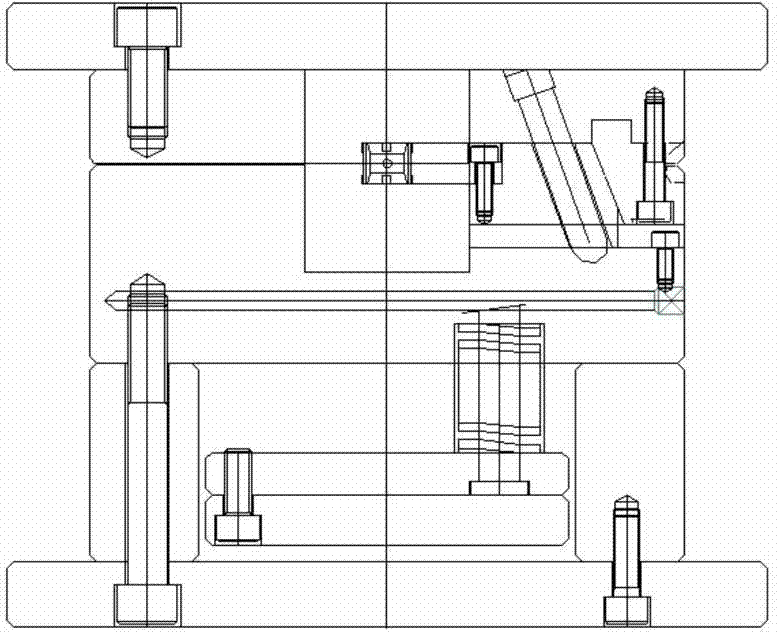

[0026] (2) Injection molding: feed the granular feed into the injection machine and feed it to the mold (see figure 1 and figure 2 ) for injection, the injection temperature is 160°C, the injection pressure is 10MPa, and the injection rate is 90% of the system injection rate. 8MPa, hold the pressure for 2s, and cool for 20s to obtain a green body.

[...

Embodiment 2

[0031] A preparation method of the orthopedic implant of the present invention, the orthopedic implant can be used for the spine, the method comprises the following steps:

[0032] (1) Feed preparation: The raw material powder is 17-4PH stainless steel powder with an average particle size of 22 μm, and the binder is composed of 40% polypropylene, 20% vegetable oil and 40% paraffin (by mass percentage). 17-4PH stainless steel powder and binder are mixed at a mass ratio of 90:10, and the resulting mixture is put into a kneader, kneaded at 180°C for 1 hour, crushed and granulated after cooling to obtain granular feed.

[0033] (2) Injection molding: feed the granular feed into the injection machine and feed it to the mold (see figure 1 and figure 2 ) for injection, the injection temperature is 155°C, the injection pressure is 9MPa, and the injection rate is 80% of the system injection rate. 7MPa, hold the pressure for 2s, and cool for 25s to obtain a green body.

[0034] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com