Novel fertilizer and preparation method thereof

A fertilizer and a new technology, applied in the field of new fertilizer and its preparation, can solve the problems of single function, complicated use, high price, etc., and achieve the effects of remarkable effect, lower commodity cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of novel fertilizer:

[0028] (1) Desalination: the concentration of bittern is above 30°Bé, heated to 90°C for 2 hours to remove the crystals, and during the constant temperature process of 90°C, the sodium chloride in bittern will crystallize and precipitate rapidly. The precipitation process will cause the crystallization of sodium chloride in the bittern that cannot be crystallized due to salt production to precipitate and further remove the salt. The constant temperature at 90°C is controlled for 2 hours so that a very small amount of sodium chloride remains in the bittern;

[0029] (2) Chlorine removal: Make the liquid concentration of removing crystals reach Baume degree more than 28 DEG B é, leave standstill for 96 hours after natural cooling, remove crystals, in the standing process liquid, magnesium chloride produces crystal precipitation and removes;

[0030] (3) bromine removal: take out the supernatant liquid from the liquid tha...

Embodiment 2

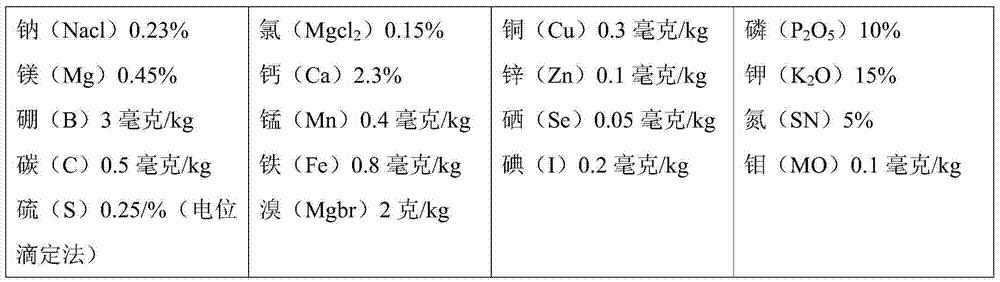

[0034] The key element content of the novel fertilizer prepared in Example 1 is as described in Table 1: (measurement condition: 26° C.)

[0035] Table 1: Key element content table of the novel fertilizer of embodiment 1

[0036]

Embodiment 3

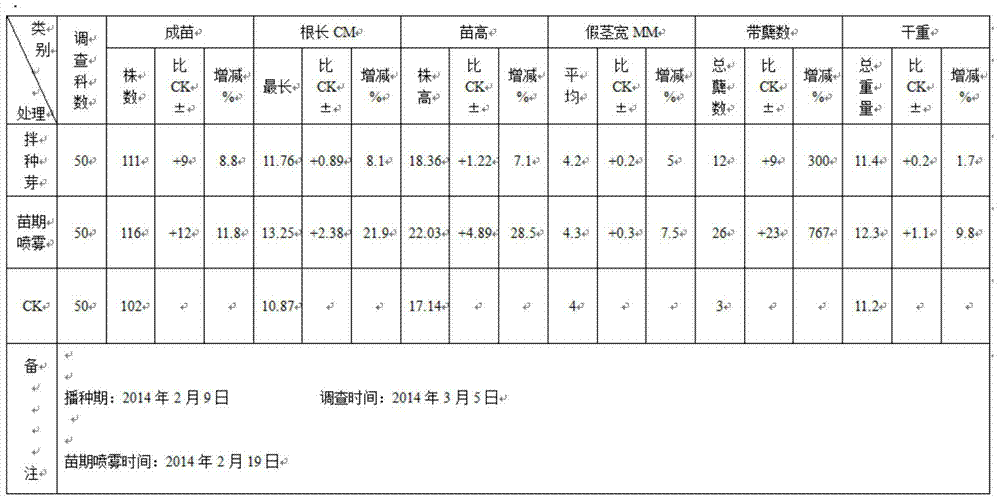

[0038] The novel fertilizer that embodiment 1 prepares is applied to the effect embodiment of seedling:

[0039] The late rice Xieyou 3550 and the early rice Teyou 524 were selected as test crops, and plastic floppy disks were used to raise seedlings, and multi-point plots were compared in Licuo Village, Qiandong Town, Raoping County, with an area of 6M 2 , repeated three times, with protective rows around. From February 9th, 2014, implement the following treatments respectively: seed dressing buds or spraying, no seed dressing buds or no spraying as contrast (wherein, no seed dressing or no spraying is used as CK), the seedling raising soil is pond mud, and the top is covered Sieve sandy soil, its specific treatment method:

[0040] A. For one mu of field, use 100g of new fertilizer and 50kg of water to mix with the seed buds, and then sow after drying in the shade;

[0041] B. Spray 100g of new fertilizer and 50kg of water for one mu of field in the three-leaf stage (car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com