Synthetic method of 2-Bromo-9-fluorenone

A synthesis method and technology of fluorenone are applied in the field of synthesis of 2-bromo-9-fluorenone, can solve problems such as unfavorable reaction operation, high toxicity, easy leakage, etc., achieve simple and safe operation, high reaction yield, improved selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

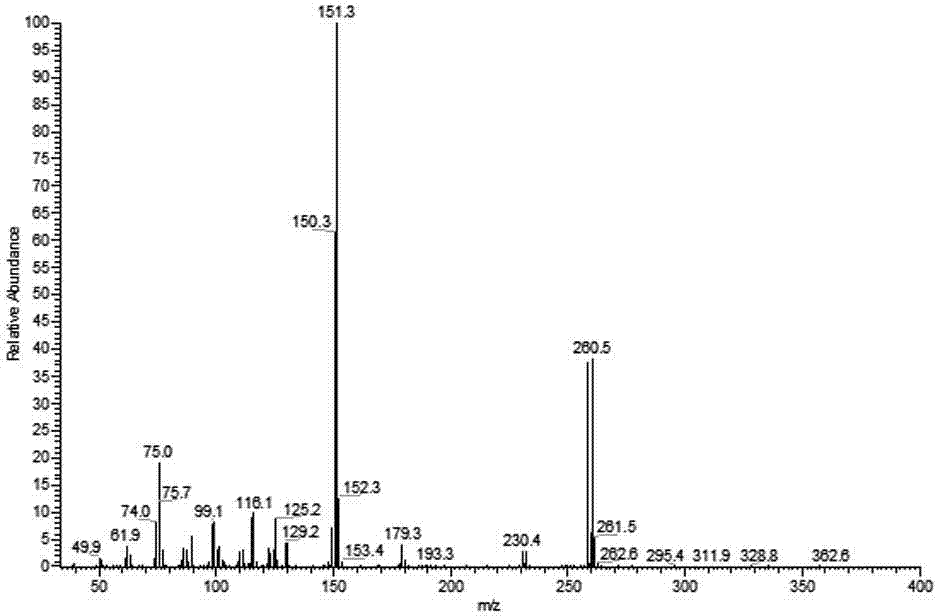

Image

Examples

Embodiment 1

[0024] The synthetic method of 2-bromo-9-fluorenone comprises the following steps:

[0025] 1) Mix 9-fluorenone (20 mmol), phase transfer catalyst (0.6 mmol tetrabutylammonium chloride) and ammonium bromide aqueous solution (40

[0026] wt%, 40 mmol ammonium bromide) and mix and heat the system temperature to 40°C, add 20 mmol potassium bromate three times within 1 hour, the weight ratio of the three additions is 1:2:1, maintain the system temperature and continue the reaction for 5 hours, the reaction temperature is 40°C, the molar ratio of 9-fluorenone, ammonium bromide, and potassium bromate is 1:2:1; the molar ratio of 9-fluorenone to tetrabutylammonium chloride (phase transfer catalyst) is 1:0.03;

[0027] 2) After the reaction, cool down to room temperature, add 10% sodium thiosulfate aqueous solution (bromine removal solution), filter, wash the filter cake with water and dry to obtain 2-bromo-9-fluorenone as a yellow solid with a yield of 96.2 %.

Embodiment 2

[0029] The synthetic method of 2-bromo-9-fluorenone comprises the following steps:

[0030] 1) Mix 9-fluorenone (10 mmol), phase transfer catalyst (2 mmol dodecyltrimethylammonium chloride) and ammonium bromide water

[0031] The solution (20 wt %, 40 mmol ammonium bromide) was mixed and the temperature of the system was heated to 95°C, and 11.5 mmol potassium bromate was added three times within 0.5 h, the weight ratio of the three additions was 1:4:1, and the system temperature was maintained to continue the reaction for 1.5 h, where the molar ratio of 9-fluorenone, ammonium bromide, and potassium bromate is 1:4:1.15; the molar ratio of 9-fluorenone to dodecyltrimethylammonium chloride (phase transfer catalyst) is 1:0.2 ;

[0032] 2) After the reaction, cool down to room temperature, add 15% sodium bisulfite aqueous solution (bromine removal solution), filter, wash the filter cake with water and dry to obtain 2-bromo-9-fluorenone as a yellow solid with a yield of 96.8 %. ...

Embodiment 3

[0034] The synthetic method of 2-bromo-9-fluorenone comprises the following steps:

[0035] 1) Mix 9-fluorenone (10 mmol), phase transfer catalyst (1.5 mmol tetradecyltrimethylammonium chloride) and ammonium bromide aqueous solution (30 wt %, 25 mmol ammonium bromide) and heat the system temperature To 75°C, add 11 mmol potassium bromate three times within 1 hour, the weight ratio of the three additions is 1:3:1, maintain the system temperature and continue the reaction for 3 hours, in which the molar ratio of 9-fluorenone, ammonium bromide, and potassium bromate is 1:2.5 : 1.1; the molar ratio of 9-fluorenone to tetradecyltrimethylammonium chloride (phase transfer catalyst) is 1:0.15;

[0036] 2) After the reaction, cool down to room temperature, add 20% sodium sulfite aqueous solution (bromine removal solution), filter and wash the filter cake with water

[0037] After drying, 2-bromo-9-fluorenone was obtained as a yellow solid with a yield of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com