Novel preparation method of organosilane crosslinked polyethylene cable material

A technology of silane cross-linking and polyethylene, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of large material performance loss, high equipment requirements, and high equipment cost, and achieve excellent insulation performance and cross-linking Shorter time and better mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

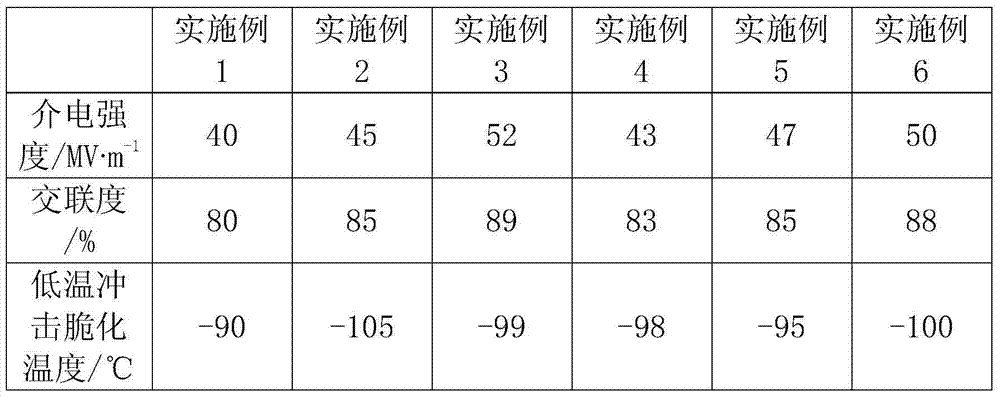

Examples

Embodiment 1

[0025] A preparation method of a novel silane crosslinked polyethylene cable material, comprising the following steps:

[0026] (1) Add polyethylene, initiator, and grafting agent into the kneader, and knead for 5 minutes at 110° C. to obtain a graft masterbatch;

[0027] (2) Add low-density polyethylene, catalyst, and antioxidant into a kneader, and knead for 3 minutes at 120° C. to obtain a catalyst masterbatch;

[0028] (3) Mix the graft masterbatch and the catalyst masterbatch, and extrude from the extruder at a die temperature of 110°C, a head temperature of 80°C, a fuselage temperature of 70°C, and a screw temperature of 30°C. Granulating to obtain the silane cross-linked polyethylene cable masterbatch;

[0029] (4) Put the silane cross-linked polyethylene cable masterbatch into a water-tight airtight space, put it under sunlight during the day, and after 2 days of treatment, dry it to obtain the silane cross-linked polyethylene cable material.

Embodiment 2

[0031] A preparation method of a novel silane crosslinked polyethylene cable material, comprising the following steps:

[0032] (1) Add polyethylene, initiator, and grafting agent into the kneader, and knead for 10 minutes at 120° C. to obtain a graft masterbatch;

[0033] (2) Add low-density polyethylene, catalyst, and antioxidant into a kneader, and knead for 8 minutes at 150° C. to obtain a catalyst masterbatch;

[0034] (3) Mix the graft masterbatch and the catalyst masterbatch, and extrude from the extruder under the conditions that the die temperature is 120°C, the die temperature is 100°C, the body temperature is 90°C, and the screw temperature is 50°C Granulating to obtain the silane cross-linked polyethylene cable masterbatch;

[0035] (4) Put the silane cross-linked polyethylene cable masterbatch into a water-tight airtight space, put it under sunlight during the day, and after 7 days of treatment, dry it to obtain the silane cross-linked polyethylene cable material...

Embodiment 3

[0037] A preparation method of a novel silane crosslinked polyethylene cable material, comprising the following steps:

[0038] (1) Add polyethylene, initiator, and grafting agent into the kneader, and knead for 6 minutes at 112°C to obtain a graft masterbatch;

[0039] (2) Add low-density polyethylene, catalyst, and antioxidant into a kneader, and knead for 4 minutes at 125° C. to obtain a catalyst masterbatch;

[0040] (3) Mix the graft masterbatch and the catalyst masterbatch, and extrude from the extruder at a die temperature of 112°C, a head temperature of 90°C, a fuselage temperature of 75°C, and a screw temperature of 35°C. Granulating to obtain the silane cross-linked polyethylene cable masterbatch;

[0041] (4) Put the silane cross-linked polyethylene cable masterbatch into a water-tight airtight space, put it under sunlight during the day, and after 3 days of treatment, dry it to obtain the silane cross-linked polyethylene cable material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com