Low-corrosion and low-formaldehyde-release polyformaldehyde composition and preparation method and application thereof

A technology of composition and formaldehyde, applied in the field of low-corrosion and low-formaldehyde-releasing polyoxymethylene composition and its preparation, can solve the problems of POM resin discoloration, inability to significantly suppress, poor long-term acid removal effect, etc., to avoid discoloration, Good absorption of formic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

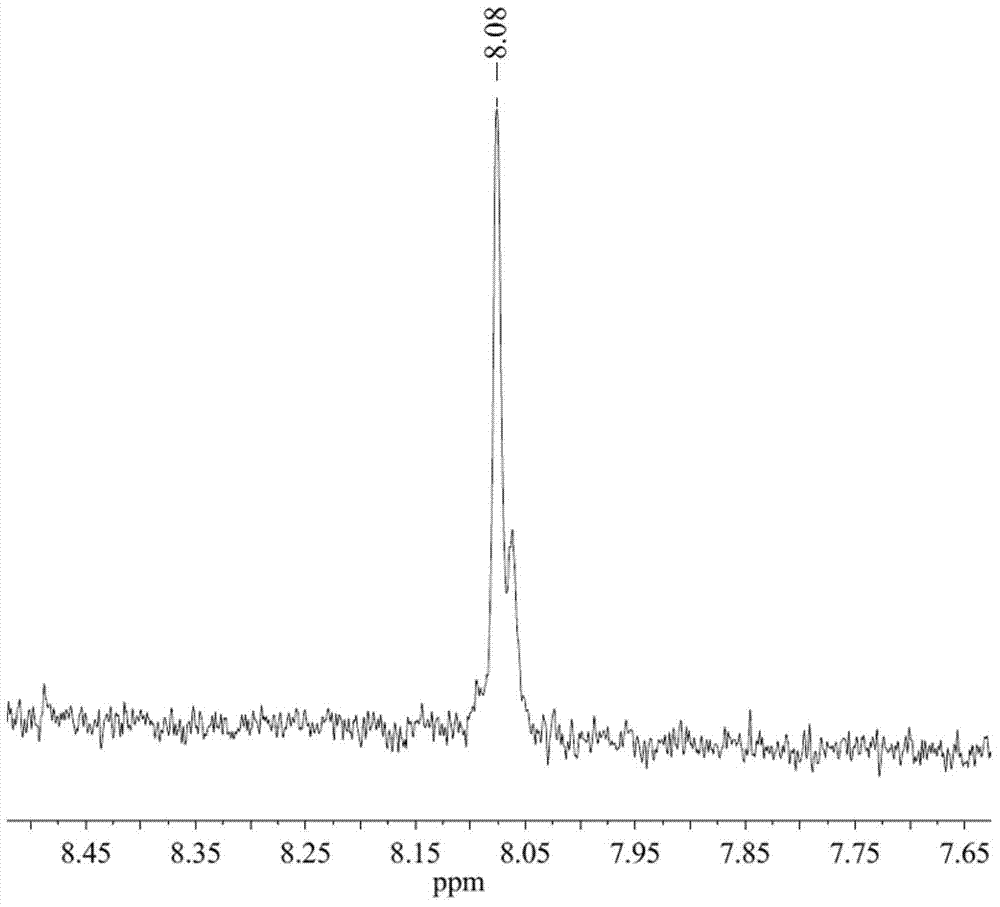

Image

Examples

Embodiment 1

[0065] Add 100 parts by weight of polyoxymethylene copolymer resin, 0.2 parts by weight of organic formaldehyde absorbent, 0.2 parts by weight of inorganic formaldehyde / formic acid absorbent, 0.6 parts by weight of antioxidant, 0.15 parts by weight of lubricant and 0.2 parts by weight of crystallization nucleating agent into a high-speed mixer Pre-mixing in the middle, and then use a twin-screw extruder for melt mixing and extrusion granulation, the processing temperature is 170 ° C, 200 ° C, 220 ° C and 230 ° C, the residence time of each temperature is not more than 5s, the screw speed It is 120r / min. The used twin-screw extruder belongs to the large-capacity evaporation (multi-stage exhaust) devolatilization twin-screw unit, the aspect ratio is 44, and the vacuum degree of each exhaust section of the twin-screw extruder is -0.07MPa during operation.

[0066] The melt index of polyoxymethylene resin used in this embodiment is 9.0g / 10min, and the weight percent content of dio...

Embodiment 2

[0073] Add 100 parts by weight of polyoxymethylene copolymer resin, 0.7 parts by weight of organic formaldehyde absorbent, 0.9 parts by weight of new inorganic formaldehyde / formic acid absorbent, 0.8 parts by weight of antioxidant, 0.6 parts by weight of lubricant and 0.1 part by weight of crystallization nucleating agent into the high-speed Pre-mixing in the mixer, and then using a twin-screw extruder for melt mixing and extrusion granulation, the processing temperature is 160 ° C, 215 ° C, 230 ° C and 240 ° C, the residence time of each temperature is not more than 5s, the screw The rotating speed is 20r / min. The twin-screw extruder used is a large-capacity evaporation (multi-stage exhaust) devolatilization twin-screw unit with an aspect ratio of 15, and the vacuum degree of each exhaust section of the twin-screw extruder is -0.08MPa during operation.

[0074] The melt index of polyoxymethylene resin used in this embodiment is 2.5g / 10min, and the weight percent content of di...

Embodiment 3

[0081] Add 100 parts by weight of polyoxymethylene copolymer resin, 3 parts by weight of organic formaldehyde absorbent, 2.5 parts by weight of new inorganic formaldehyde / formic acid absorbent, 2 parts by weight of antioxidant, 1.5 parts by weight of lubricant and 1 part by weight of crystallization nucleating agent into the high-speed Pre-mixing in the mixer, and then using a twin-screw extruder for melt mixing and extrusion granulation, the processing temperature is 175 ° C, 210 ° C, 230 ° C and 245 ° C, the residence time of each temperature is not more than 5s, the screw The rotating speed is 400r / min. The used twin-screw extruder belongs to the large-capacity evaporation (multi-stage exhaust) devolatilization twin-screw unit, the aspect ratio is 65, and the vacuum degree of each exhaust section of the twin-screw extruder is -0.09MPa during operation.

[0082] The melt index of polyoxymethylene resin used in this embodiment is 27.0g / 10min, and the weight percent of dioxola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com