Novel magneto-optic single crystal material growing method

A single crystal material and growth method technology, applied in crystal growth, liquid phase epitaxy layer growth, chemical instruments and methods, etc., can solve the problems of insufficient thickness and long growth cycle of magneto-optic thin films, etc., to facilitate processing and realize Effects of device integration and shortened growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

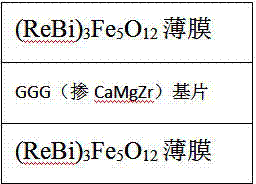

[0018] A Novel Magneto-optical Single Crystal Material (ReBi) 3 Fe 5 o 12 Growth technology, including the following steps: (A) PbO with a purity of more than 99.99%, B 2 o 3 、 Bi 2 o 3 , Fe 2 o 3 、Re 2 o 3 The powder is mixed evenly according to the determined ratio, put into the platinum crucible treated with nitric acid, and put into the liquid phase epitaxy furnace; Melt and the composition is uniform; (C) Clean the GGG substrate with ultrasonic waves in deionized water, bake the substrate under an infrared lamp with bamboo tweezers, put it on a cleaned platinum jig, and put the jig into an epitaxy furnace After preheating in the preheating zone, put it into the solution for liquid phase epitaxy; during the epitaxy process, control the cooling rate and substrate rotation speed according to the required film thickness; (D) After the epitaxy is completed, lift t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com