Optically-excited fiber grating cantilever beam harmonic oscillator vacuum degree sensor

A vacuum sensor, fiber grating technology, applied in vacuum gauges, instruments, measuring devices, etc., can solve the problems of low excitation efficiency, poor anti-electromagnetic interference ability, and difficult packaging of silicon micromechanical sensors, and achieve enhanced reliability, device simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

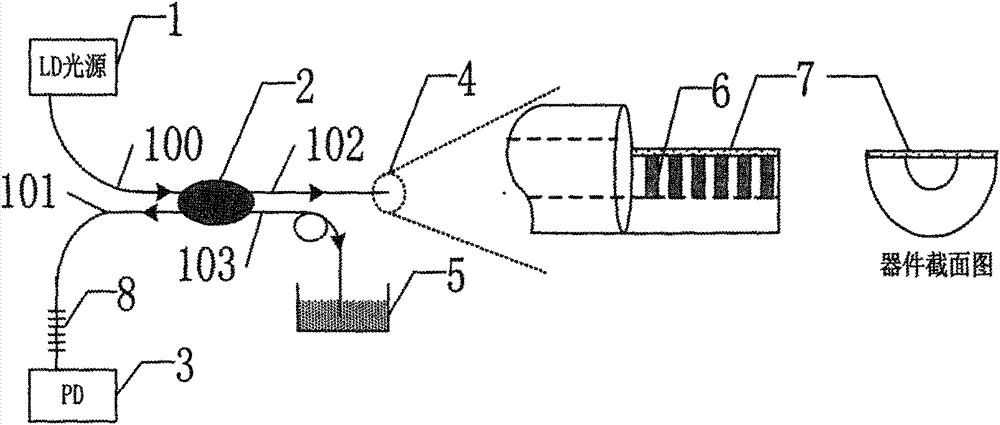

[0019] figure 1 As shown, a light-excited fiber grating cantilever beam resonator vacuum sensor includes an LD light source (1), an optical fiber directional coupler (2), a photodetector (3), a sensing probe (4), and a matching liquid (5 ), microfabricated fiber grating (6), metal coating (7), matched filter FBG (8); described LD light source (1) is connected with a port (100) of the fiber directional coupler, and two ports of the directional coupler The port (101) is connected to the matched filter FBG (8), the photodetector (3) is connected to the other end of the matched filter FBG (8), the three ports (102) of the fiber directional coupler are connected to the sensor probe (4), and the fiber directional The four ports (103) of the coupler are immersed in the matching liquid (5) to form a complete vacuum detection system.

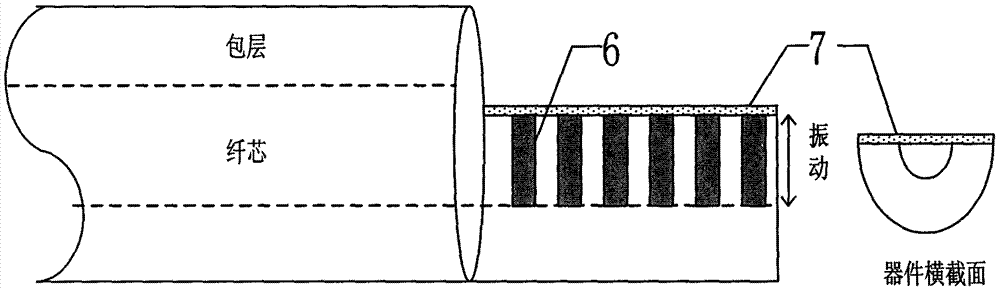

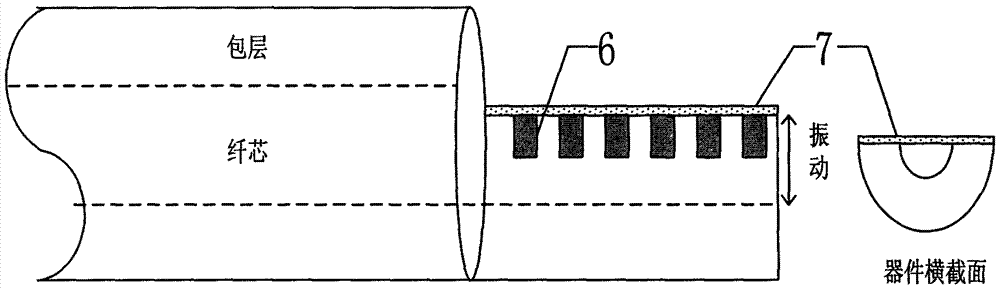

[0020] figure 2 As shown, the fiber grating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com