Method for measuring lanthanum content in lanthanum-iron alloy

A technology of lanthanum-iron alloy and determination method, which is applied in the field of rare earth iron alloy, can solve the problems of lack of determination method of lanthanum-iron alloy and the like, and achieves the effects of low cost, stable method and easy mastery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

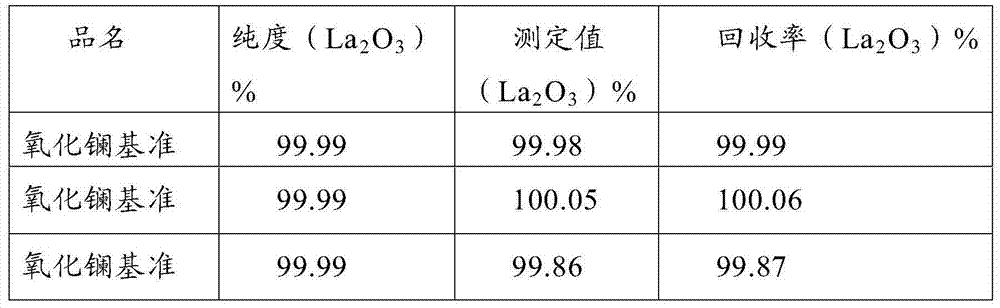

Examples

Embodiment Construction

[0026] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0027] 1. Method summary:

[0028] Decompose the sample with nitric acid, at pH=1.8-2.0 (after adding oxalic acid (10%), add cresol red indicator (0.2%) ethanol solution, adjust the solution from red to yellow with ammonia water (50%) pH=1.8-2.0), use oxalic acid to measure the precipitated rare earth, filter, wash, burn and weigh.

[0029] 2: Reagents:

[0030] 2.1: Ethanol solution of cresyl red indicator (0.2%).

[0031] 2.2: Oxalic acid-ammonium oxalate mixture (1% each)

[0032] 2.3: Oxalic acid (10%)

[0033] 2.4: Ammonia (50%)

[0034] 2.5: Nitric Acid (50%)

[0035] 3: Sampling and sample preparation shall be carried out in accordance with the standards for sampling and preparation of ferroalloys.

[0036] 4: Sample size:

[0037] Weigh the sample 0.2000g

[0038] 5: Analysis steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com