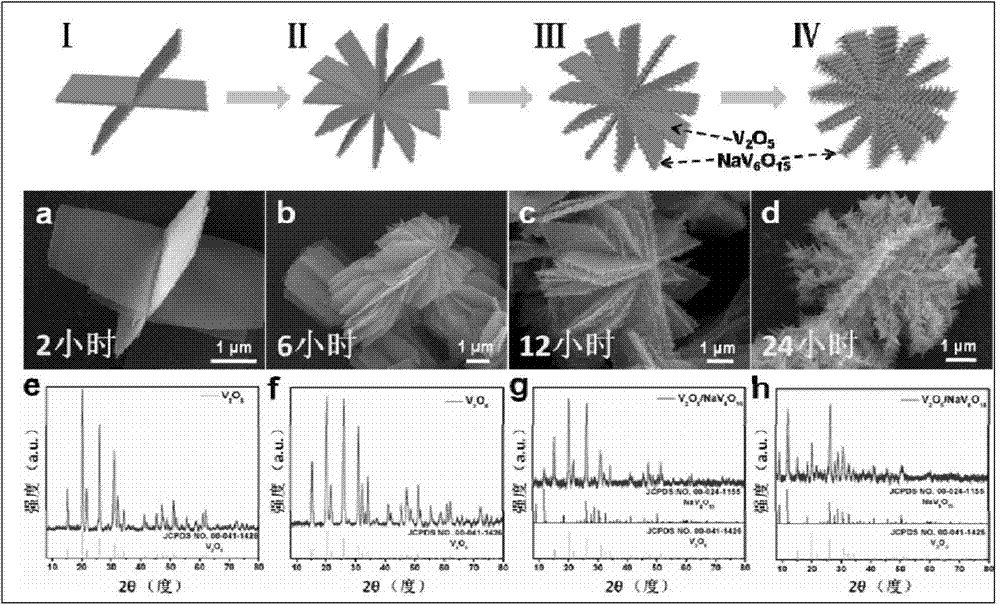

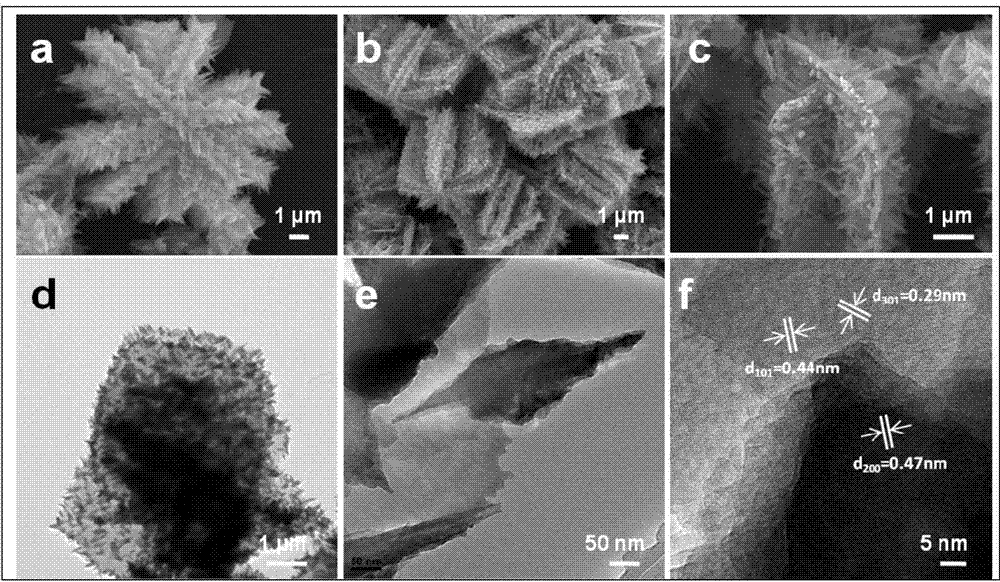

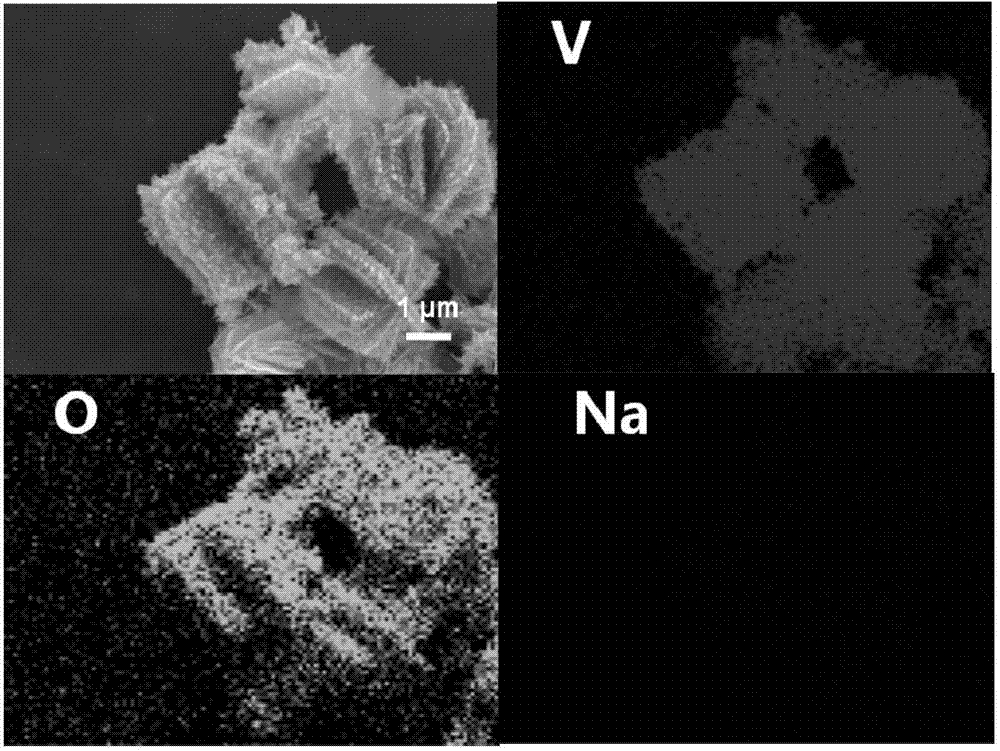

Three-dimensional hierarchical heterostructure nano-material, and gradient hydro-thermal preparation method and application thereof

A technology of heterostructures and nanomaterials, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problem of difficulty in obtaining three-dimensional heterostructured nanostructures, and achieve large specific surface area, reduced damage, and excellent electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Weigh 0.14g ammonium metavanadate and 0.25g citric acid monohydrate, add 35mL deionized water, stir for about one minute to form a uniform transparent yellow solution;

[0045] 2) Add 0.5 g of sodium lauryl sulfate to the solution in step 1), and magnetically stir it in a constant temperature water bath at 50° C. for 4 hours to dissolve it and form a transparent and uniform dark blue solution;

[0046] 3) Take out the precursor solution obtained in step 2) from the water bath and let it stand for 1 min, transfer it to a 50mL reaction kettle, and conduct a hydrothermal reaction in a constant temperature oven at 180°C for 24 hours;

[0047] 4) After the reaction kettle in step 3) is naturally cooled to room temperature, pour off the upper layer solution, obtain the black precipitate at the bottom, wash and centrifuge;

[0048] 5) drying the sample obtained in step 4) in a vacuum oven at 70°C for 6 hours;

[0049] 6) Calcining the dried sample in step 5) at a heating r...

Embodiment 2

[0058] 1) Weigh 0.14g ammonium metavanadate and 0.25g citric acid monohydrate, add 35mL deionized water, stir for about one minute to form a uniform transparent yellow solution;

[0059] 2) Add 0.1 g of sodium lauryl sulfate to the solution in step 1), and magnetically stir it in a constant temperature water bath at 50°C for 4 hours to dissolve it and form a transparent and uniform dark blue solution;

[0060] 3) Take out the precursor solution obtained in step 2) from the water bath and let it stand for 1 minute, transfer it to a 50mL reaction kettle, and conduct a hydrothermal reaction in a constant temperature oven at 180°C for 24 hours;

[0061] 4) After the reaction kettle in step 3) is naturally cooled to room temperature, pour off the upper layer solution, obtain the black precipitate at the bottom, wash and centrifuge;

[0062] 5) drying the sample obtained in step 4) in a vacuum oven at 70°C for 6 hours;

[0063] 6) Calcining the dried sample in step 5) at a heating ...

Embodiment 3

[0066] 1) Weigh 0.14g ammonium metavanadate and 0.25g citric acid monohydrate, add 35mL deionized water, stir for about one minute to form a uniform transparent yellow solution;

[0067] 2) Add 0.3 g of sodium lauryl sulfate to the solution in step 1), and magnetically stir it in a constant temperature water bath at 50° C. for 4 hours to dissolve it and form a transparent and uniform dark blue solution;

[0068] 3) Take out the precursor solution obtained in step 2) from the water bath and let it stand for 1 minute, transfer it to a 50mL reaction kettle, and conduct a hydrothermal reaction in a constant temperature oven at 180°C for 24 hours;

[0069] 4) After the reaction kettle in step 3) is naturally cooled to room temperature, pour off the upper layer solution, obtain the black precipitate at the bottom, wash and centrifuge;

[0070] 5) drying the sample obtained in step 4) in a vacuum oven at 70°C for 6 hours;

[0071] 6) Calcining the dried sample in step 5) at a heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com