Corn seed treatment agent

A technology for seed treatment and corn, applied in the directions of pesticides, biocides, fungicides, etc., can solve the problems of neglecting sterilization and seedling strengthening, and only considering insecticides in seed soaking agents, and achieves a good control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

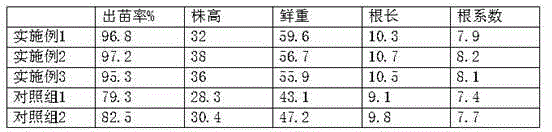

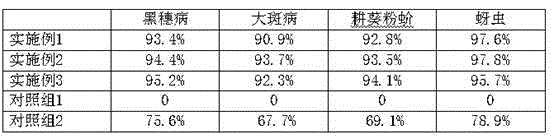

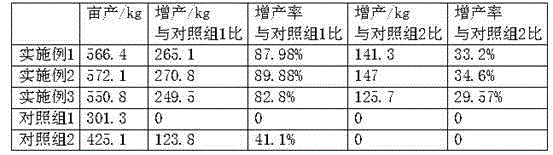

Embodiment 1

[0021] A corn seed treatment agent, which is prepared by mixing the following raw materials in weight percentage: paclobutrazol 3%, uniconazole 5%, amino oligosaccharin 1.2%, chitosan 0.8%, styrylphenol polyoxygen Vinyl ether 0.5%, sodium lignosulfonate 3%, butyl glycol ether 2%, simethicone 2%, potassium sorbate 0.5%, capillary extract 0.02%, pomegranate peel extract 0.02%, indole 0.1% acetic acid, 0% pH adjuster, and the balance is water.

Embodiment 2

[0023] A corn seed treatment agent, which is prepared by mixing the following raw materials in weight percentage: paclobutrazol 6%, uniconazole 10%, amino oligosaccharin 1%, chitosan 1.2%, styrylphenol polyoxygen Vinyl ether 5%, sodium lignosulfonate 5%, butyl glycol ether 0.1%, simethicone 5%, potassium sorbate 0.8%, capillary extract 0.03%, pomegranate peel extract 0.03%, indole 0.3% acetic acid, 1% pH adjuster, and the balance is water.

Embodiment 3

[0025] A corn seed treatment agent, which is prepared by mixing the following raw materials in weight percentage: 5% paclobutrazol, 8% uniconazole, 1.5% amino oligosaccharin, 1% chitosan, styrylphenol polyoxygen Vinyl ether 2%, sodium lignosulfonate 0.5%, butyl glycol ether 0.8%, simethicone 0.1%, potassium sorbate 0.7%, capillary extract 0.01%, pomegranate peel extract 0.01%, indole 0.2% acetic acid, 1% pH adjuster, and the balance is water.

[0026] The production method of the capillary extract in the above-mentioned examples 1, 2, and 3 is as follows: take the capillary and add 10 times the mass of 90% ethanol for percolation; collect the percolation liquid, filter, and concentrate the filtrate under reduced pressure to a relative density of 60-65 °C For 1.10-1.15 clear ointment, add 6-7 times the amount of water to the clear ointment, refrigerate at 0-4°C, let stand for 24 hours, filter, heat the filtrate at 120°C for 1 hour, refrigerate at 0-4°C, let stand for 24 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com