Charged TiO2/polyelectrolyte composite nanofiltration membrane as well as preparation method and application thereof

A technology of composite nanofiltration membrane and polyelectrolyte, which is applied in the field of charged TiO2/polyelectrolyte composite nanofiltration membrane, can solve the problems of difficulty in obtaining nanofiltration membrane, high requirements for base membrane, and many side reactions, and achieve good photocatalytic performance , Composite membrane structure is uniform, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

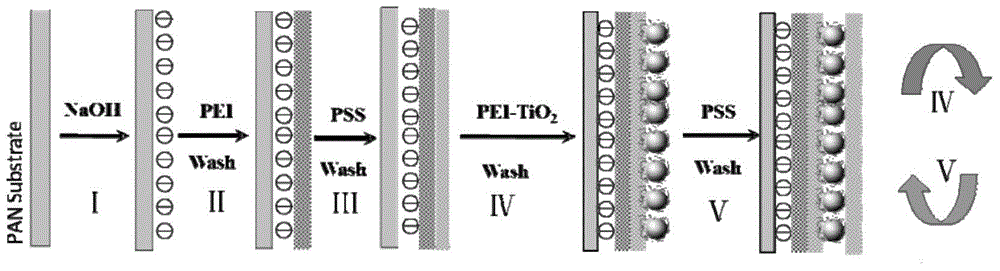

[0025] (1) Pretreat the base membrane to make its surface negatively charged: take the ultrafiltration membrane as the base membrane, use 1.0mol / L sodium hydroxide solution to treat the base membrane at 30°C for 30min, and then use deionized Rinse with water until the pH value is 7;

[0026] (2) Preparation of polyelectrolyte solution: Dissolve cationic polyelectrolyte polyetherimide (PEI) and anionic polyelectrolyte sodium polystyrene sulfonate (PSS) in deionized water respectively, and prepare a solution with a solubility of 5.0 g / L Polyetherimide (PEI) solution and polystyrene sulfonate sodium (PSS) solution, and the modified negatively charged PSS-TiO 2 Added to polystyrene sulfonate sodium (PSS) film-making liquid, prepared 0.2g / L nanoparticle PSS-TiO 2 Sodium polystyrene sulfonate (PSS) membrane solution, magnetically stirred for 4h;

[0027] (3) Self-assembled base layer: soak the negatively charged base film treated in step (1) in the polyetherimide (PEI) solution pr...

Embodiment 2

[0032] (1) Pretreat the base membrane to make its surface negatively charged: take the ultrafiltration membrane as the base membrane, use 1.0mol / L sodium hydroxide solution to treat the base membrane at 30°C for 30min, and then use deionized Rinse with water until the pH value is 7;

[0033] (2) Preparation of polyelectrolyte solution: Dissolve cationic polyelectrolyte polyetherimide (PEI) and anionic polyelectrolyte sodium polystyrene sulfonate (PSS) in deionized water respectively, and prepare a solution with a solubility of 5.0 g / L Polyetherimide (PEI) solution and polystyrene sulfonate sodium (PSS) solution, and the modified negatively charged PSS-TiO 2 Added to polystyrene sulfonate sodium (PSS) film-making liquid, prepared 0.2g / L nanoparticle PSS-TiO 2 Sodium polystyrene sulfonate (PSS) membrane solution, magnetically stirred for 2h;

[0034] (3) Self-assembled base layer: soak the negatively charged base film treated in step (1) in the polyetherimide (PEI) solution pr...

Embodiment 3

[0040] (1) Pretreat the base membrane to make its surface negatively charged: take the ultrafiltration membrane as the base membrane, use 2.0mol / L sodium hydroxide solution to treat the base membrane at 30°C for 30min, and then use deionized Rinse with water until the pH value is 7;

[0041] (2) Preparation of polyelectrolyte solution: Dissolve cationic polyelectrolyte polyetherimide (PEI) and anionic polyelectrolyte sodium polystyrene sulfonate (PSS) in deionized water respectively, and prepare a solution with a solubility of 5.0 g / L Polyetherimide (PEI) solution and polystyrene sulfonate sodium (PSS) solution, and the modified positively charged PEI-TiO 2 Added to the polyetherimide (PEI) film-making solution to prepare 0.12g / L nanoparticle PEI-TiO 2 Polyetherimide (PEI) film-making liquid, magnetically stirred for 4h;

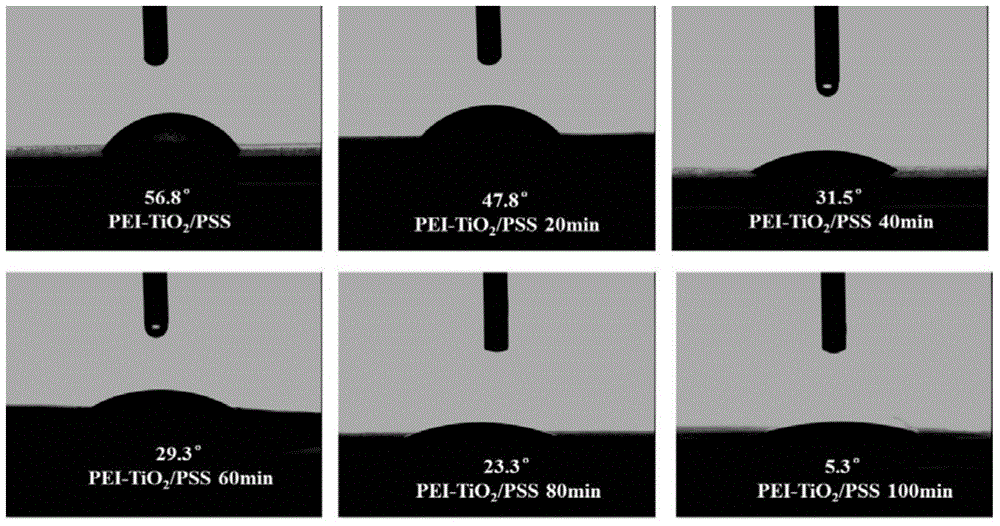

[0042] (3) Self-assembled base layer: soak the negatively charged base film treated in step (1) in the polyetherimide (PEI) solution prepared in step (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com