Preparation and application of plasma gold/zinc oxide composite nanosheet array device

A nanosheet array and plasma technology is applied in the field of preparation of photocatalytic device materials, which can solve the problems of poor stability of Au/ZnO composites, narrow photoresponse range, and high raw material cost, so as to overcome the difficulty of multi-electron reduction and improve the Photocatalytic efficiency and effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

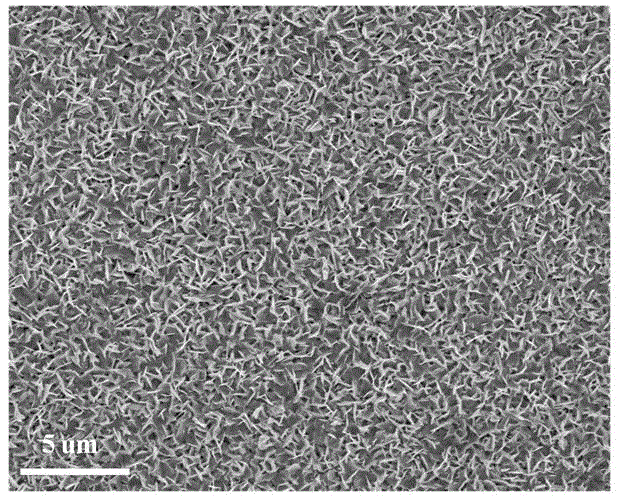

Image

Examples

Embodiment 1

[0032] Weigh 0.06 g of zinc acetate in 60 ml of ethanol solution and keep stirring for 30 minutes to fully dissolve it. The cleaned conductive glass (FTO) was dipped in the above solution for 10 seconds with the conductive side facing down, then taken out and blown dry with nitrogen. Repeat the dipping-nitrogen drying step 5 times. Then transfer the impregnated conductive glass to a muffle furnace, control the heating rate, and bake at a rate of 2°C / min at 350°C for 30 minutes in an air atmosphere to obtain a conductive glass evenly covered with zinc oxide seeds.

[0033] Weigh 0.71 g of zinc nitrate hexahydrate (in 30 ml of deionized water, stir until clear and transparent to obtain solution A, and weigh 0.33 g of hexamethylenetetramine in 30 ml of deionized water, stir until clear and transparent to obtain solution A B. Slowly pour the two solutions of A and B into a 100 ml polytetrafluoroethylene autoclave while stirring, and continue to stir for 10 minutes after the dropw...

Embodiment 2

[0037] Weigh 0.06 g of zinc acetate in 30 ml of ethanol solution and keep stirring for 30 minutes to fully dissolve it. The cleaned conductive glass (FTO) was dipped in the above solution for 20 seconds with the conductive side facing down, then taken out and blown dry with nitrogen. Repeat the dipping-nitrogen drying step 10 times. Then transfer the impregnated conductive glass to a muffle furnace, control the heating rate, and bake at a rate of 10°C / min in an air atmosphere at 500°C for 50 minutes to obtain a conductive glass evenly covered with zinc oxide seeds.

[0038] Weigh 0.71 g of zinc nitrate hexahydrate in 30 ml of deionized water, stir until clear and transparent to obtain solution A, and weigh 0.33 g of hexamethylenetetramine in 30 ml of deionized water, stir until clear and transparent to obtain solution B . Slowly pour the two solutions of A and B into a 100 ml polytetrafluoroethylene autoclave while stirring, and continue to stir for 10 minutes after the drop...

Embodiment 3

[0042] Weigh 0.06 g of zinc acetate in 30 ml of ethanol solution and keep stirring for 30 minutes to fully dissolve it. The cleaned conductive glass (FTO) was dipped in the above solution for 20 seconds with the conductive side facing down, then taken out and blown dry with nitrogen. Repeat the dipping-nitrogen drying step 10 times. Then transfer the impregnated conductive glass to a muffle furnace, control the heating rate, and bake at a rate of 10°C / min in an air atmosphere at 500°C for 50 minutes to obtain a conductive glass evenly covered with zinc oxide seeds.

[0043] Weigh 0.71 g of zinc nitrate hexahydrate (in 30 ml of deionized water, stir until clear and transparent to obtain solution A, and weigh 0.33 g of hexamethylenetetramine in 30 ml of deionized water, stir until clear and transparent to obtain solution A B. Slowly pour the two solutions of A and B into a 100 ml polytetrafluoroethylene autoclave while stirring, and continue to stir for 10 minutes after the dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com