Preparation and application of hierarchical porous copper phosphide/carbon hydrolysis electrocatalysts derived from copper-containing metal-organic frameworks

An organic framework, hierarchical porous technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of large size, cumbersome and complicated material preparation process, low product yield, etc., achieve uniform distribution of active centers, improve catalytic performance, The effect of high catalyst yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Hierarchically porous copper phosphide / carbon (Cu 3 P@C) A method for preparing an electrolytic water catalyst, comprising the following steps:

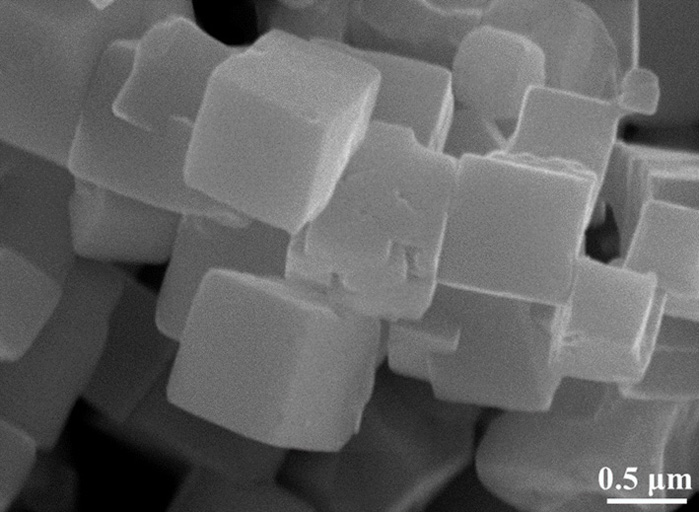

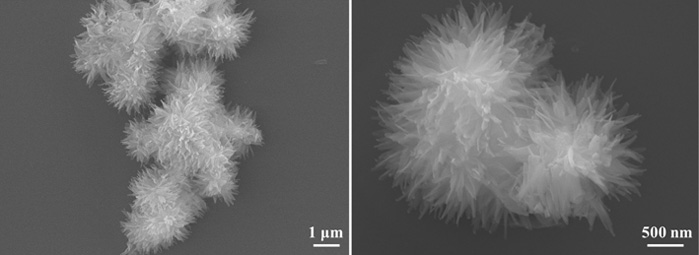

[0031] a) Preparation of sea urchin-like Cu-MOF: In a three-neck flask, 5 mg of Cu with a side length of 300-600 nm 2 O cubes were dispersed in 10 mL of N,N-dimethylformamide (DMF) solvent (0.5 mg / mL) and magnetically stirred to form solution A. 0.021 g of trimesic acid was fully dissolved in 10 mL of DMF solvent (0.01 mol / L) to form solution B. Add solution B to solution A under magnetic stirring, and react at 25°C for 5 min. Then the stirring was stopped, and the solution was aged for 30 min. Cool, centrifuge at 8000 rpm for 5 min, wash with deionized water and ethanol, and dry overnight at 60°C under vacuum to obtain the Cu-MOF precursor.

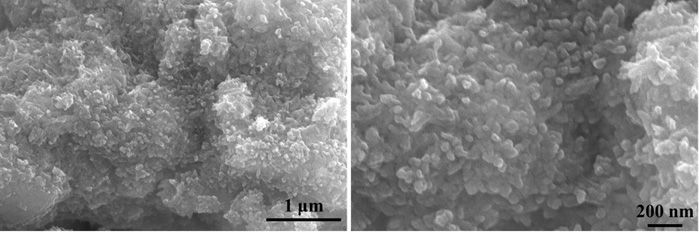

[0032] b) Cu 3 P@C catalyst material preparation: 50 mg of Cu-MOF precursor and 1000 mg of NaH 2 PO 2 Place them at a distance of 2-5 cm, and in an argon or nitrogen atmosphere, r...

Embodiment 2

[0035] Hierarchically porous copper phosphide / carbon (Cu 3 P@C) A method for preparing an electrolytic water catalyst, comprising the following steps:

[0036] a) Preparation of sea urchin-like Cu-MOF: In a three-necked flask, 8 mg of Cu with a side length of 300-600 nm 2 O cubes were dispersed in 10 mL of N,N-dimethylformamide (DMF) solvent (0.8 mg / mL) and magnetically stirred to form solution A. 0.105 g of trimesic acid was fully dissolved in 10 mL of DMF solvent (0.05 mol / L) to form solution B. Add solution B to solution A under magnetic stirring, and react at 60°C for 20 min. Then the stirring was stopped, and the solution was aged for 90 min. Cool, centrifuge at 8000 rpm for 5 min, wash with deionized water and ethanol, and dry overnight at 60°C under vacuum to obtain the Cu-MOF precursor.

[0037] b) Cu 3 Preparation of P@C catalyst material: 50 mg of Cu-MOF precursor and 500 mg of NaH 2 PO 2 Place them at a distance of 2-5 cm, and in an argon or nitrogen atmosphe...

Embodiment 3

[0040] Hierarchically porous copper phosphide / carbon (Cu 3 P@C) A method for preparing an electrolytic water catalyst, comprising the following steps:

[0041] a) Preparation of sea urchin-like Cu-MOF: In a three-necked flask, 12 mg of Cu with a side length of 300-600 nm 2 O cubes were dispersed in 10 mL of N,N-dimethylformamide (DMF) solvent (1.2 mg / mL) and magnetically stirred to form solution A. 0.83 g of terephthalic acid was fully dissolved in 10 mL of DMF solvent (0.5 mol / L) to form solution B. Add solution B to solution A under magnetic stirring, and react at 90°C for 40 min. Then the stirring was stopped, and the solution was aged for 120 min. Cool, centrifuge at 8000 rpm for 5 min, wash with deionized water and ethanol, and dry overnight at 60°C under vacuum to obtain the Cu-MOF precursor.

[0042] b) Cu 3 Preparation of P@C catalyst material: 50 mg of Cu-MOF precursor and 400 mg of NaH 2 PO 2 Place them at a distance of 2-5 cm, and in an argon or nitrogen atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com