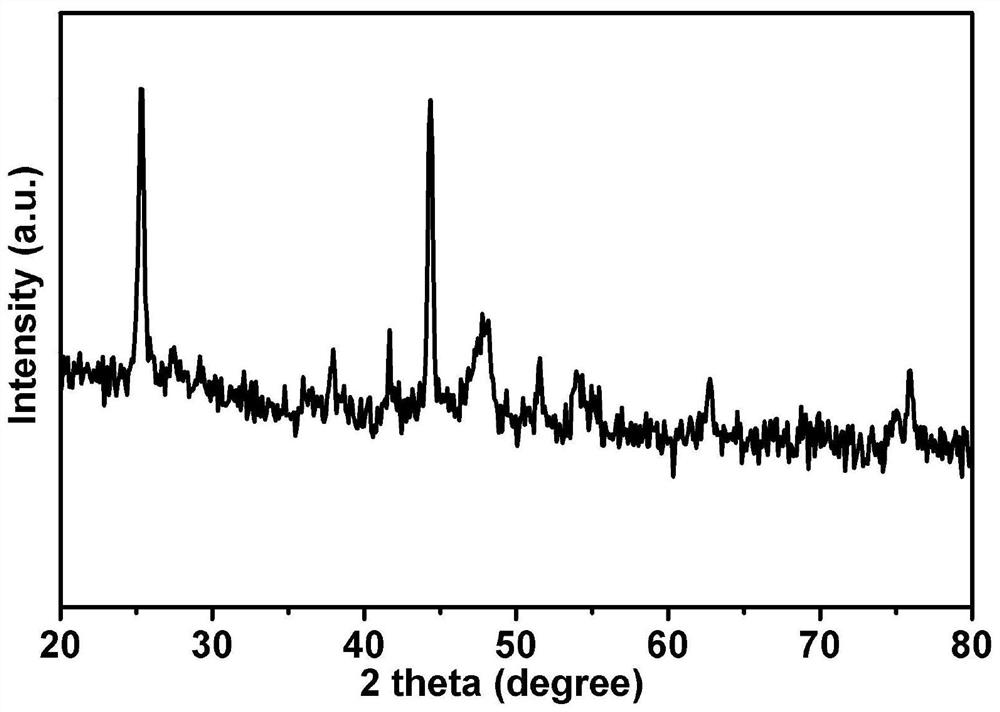

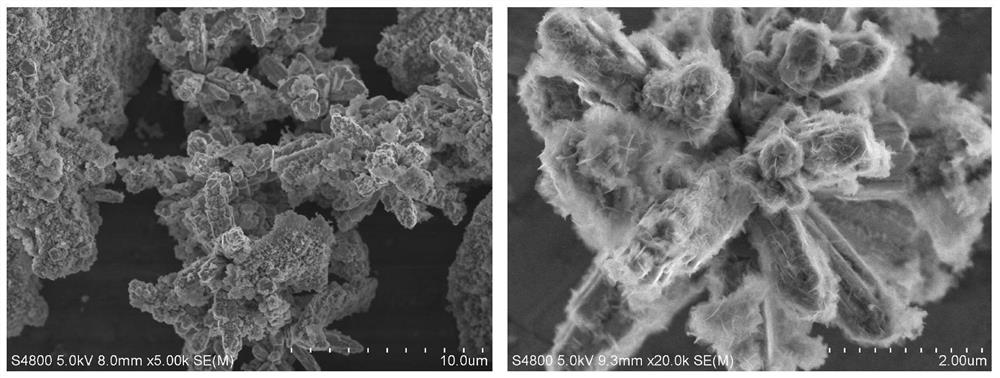

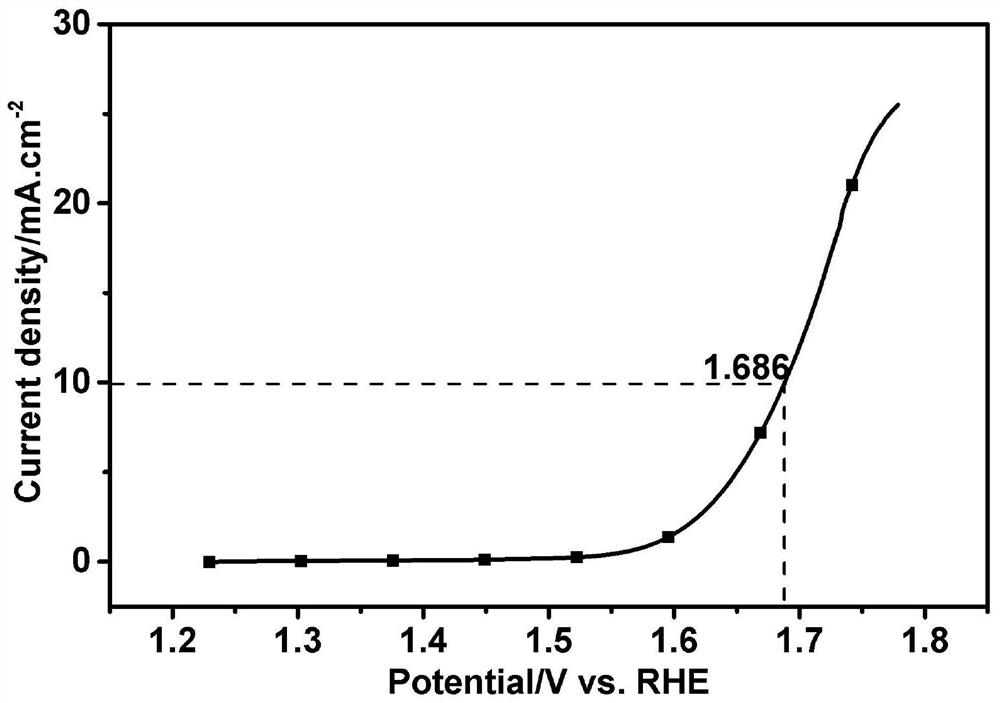

Co dendrite electrocatalyst and preparation method thereof

A technology of electrocatalysts and nanorods, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of less active sites for oxygen production, poor oxygen production performance, and small specific surface area. To achieve the effect of promoting the process of electrolysis of oxygen and increasing the exposure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 3.0 g of trimesic acid and 0.6 g of titanium dioxide P25, dissolve the two together in a solution prepared from 5 ml of ethanol and 10 ml of deionized water, and stir until the solution is uniform;

[0028] (2) Pour the prepared solution into a clean hydrothermal reaction kettle, conduct a hydrothermal reaction at 100°C for 24 hours, then wash and dry;

[0029] (3) configure 0.1mol / L cobalt chloride hexahydrate aqueous solution and 25mol / L sodium hydroxide aqueous solution respectively;

[0030] (4) Measure 10ml of the cobalt chloride hexahydrate aqueous solution obtained in step (3) in a beaker, add 150mg of titanium dioxide P25 obtained in step (2), stir to obtain a homogeneous solution, and then add 0.5ml of the obtained solution in step (3) Sodium hydroxide aqueous solution, stir to obtain a uniform solution, then add 1.5ml of hydrazine hydrate, stir until the solution is uniform;

[0031] (5) Pour the prepared solution into a clean hydrothermal reaction ...

Embodiment 2

[0036] (1) Weigh 3.0 g of trimesic acid and 0.6 g of titanium dioxide P25, dissolve the two together in a solution prepared from 5 ml of ethanol and 10 ml of deionized water, and stir until the solution is uniform;

[0037] (2) Pour the prepared solution into a clean hydrothermal reaction kettle, conduct a hydrothermal reaction at 100°C for 24 hours, then wash and dry;

[0038] (3) configure 0.1mol / L cobalt chloride hexahydrate aqueous solution and 25mol / L sodium hydroxide aqueous solution respectively;

[0039] (4) Measure 10ml of the cobalt chloride hexahydrate aqueous solution obtained in step (3) in a beaker, add 50mg of P25 obtained in step (2), stir to obtain a homogeneous solution, and then add 0.5ml of hydrogen obtained in step (3) Sodium oxide aqueous solution, stir to obtain a uniform solution, then add 1.5ml of hydrazine hydrate, stir until the solution is uniform;

[0040] (5) Pour the prepared solution into a clean hydrothermal reaction kettle, and conduct a hydr...

Embodiment 3

[0045] (1) Weigh 3.0 g of trimesic acid and 0.6 g of titanium dioxide P25, dissolve the two together in a solution prepared from 5 ml of ethanol and 10 ml of deionized water, and stir until the solution is uniform;

[0046] (2) Pour the prepared solution into a clean hydrothermal reaction kettle, conduct a hydrothermal reaction at 100°C for 24 hours, then wash and dry;

[0047] (3) configure 0.1mol / L cobalt chloride hexahydrate aqueous solution and 25mol / L sodium hydroxide aqueous solution respectively;

[0048] (4) Measure 10ml of the cobalt chloride hexahydrate aqueous solution obtained in step (3) in a beaker, add 10mg of P25 obtained in step (2), stir to obtain a homogeneous solution, and then add 0.5ml of hydrogen obtained in step (3) Sodium oxide aqueous solution, stir to obtain a uniform solution, then add 1.5ml of hydrazine hydrate, stir until the solution is uniform;

[0049] (5) Pour the prepared solution into a clean hydrothermal reaction kettle, and conduct a hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com