Graphene and preparation method thereof

A graphene and graphite technology, applied in the field of graphene and its preparation, can solve the problems of graphene damage, incomplete lamella structure, many defects, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of graphene, comprises the following steps:

[0029] a), carry out first reaction after graphite, acid and oxidizing agent are mixed, obtain graphite intercalation compound, described acid comprises concentrated sulfuric acid, and described oxidizing agent comprises chlorate;

[0030] b), performing a second reaction with the graphite intercalation compound and a peroxide to obtain an intermediate product, the peroxide comprising hydrogen peroxide;

[0031] c), performing ultrasonic stripping on the intermediate product to obtain graphene.

[0032] The present invention adopts concentrated sulfuric acid and chlorate to oxidize graphite, and the oxidation of graphite by concentrated sulfuric acid and chlorate oxidation system is relatively weak, so that the degree of destruction of the sheet structure of prepared graphene is small; In the process of preparing graphene, hydrogen peroxide will react with the concentrated...

Embodiment 1

[0056] 10g of natural graphite with a particle size of 150 μm and 200g of mass concentration are mixed evenly with 98% concentrated sulfuric acid, and then 40g of NaClO is added to the resulting mixture. 3 Carrying out the first reaction at 15° C. for 12 hours to obtain a graphite intercalation compound;

[0057] Add 60g of 30% aqueous hydrogen peroxide solution to the graphite intercalation compound and carry out the second reaction at 30°C to obtain a gray-black worm-like reaction product; filter the reaction product with filter paper and wash with water until neutral , to get the intermediate product;

[0058] Dispersing the intermediate product in water, performing ultrasonic exfoliation at 1000w for 10 min to obtain a graphene solution; freeze-drying the graphene solution to obtain a graphene powder.

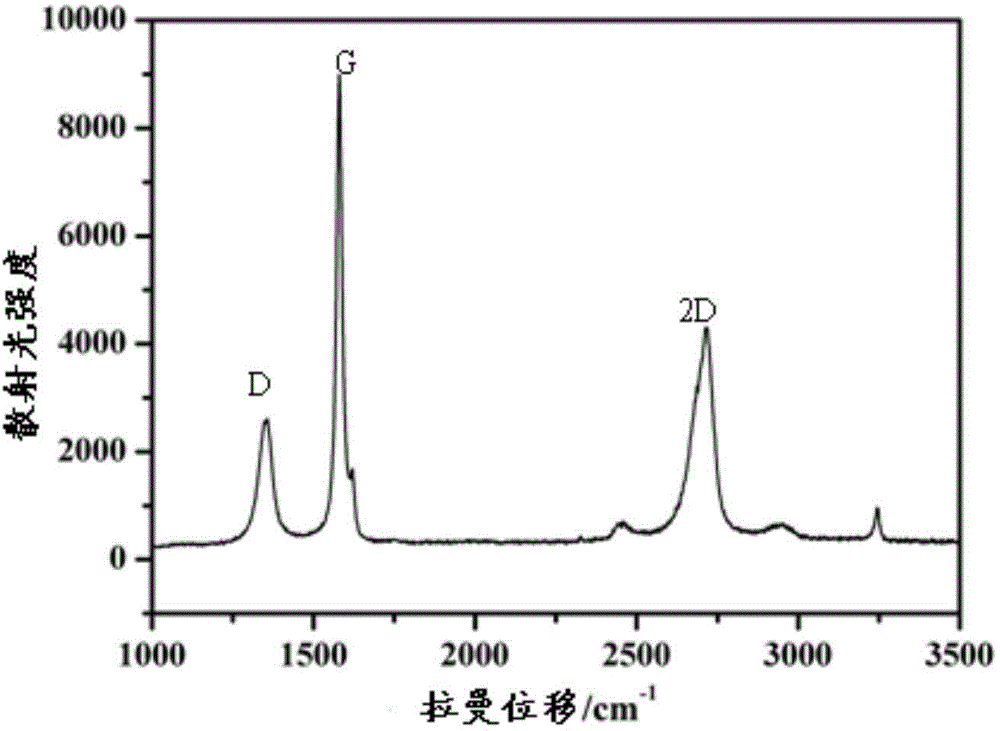

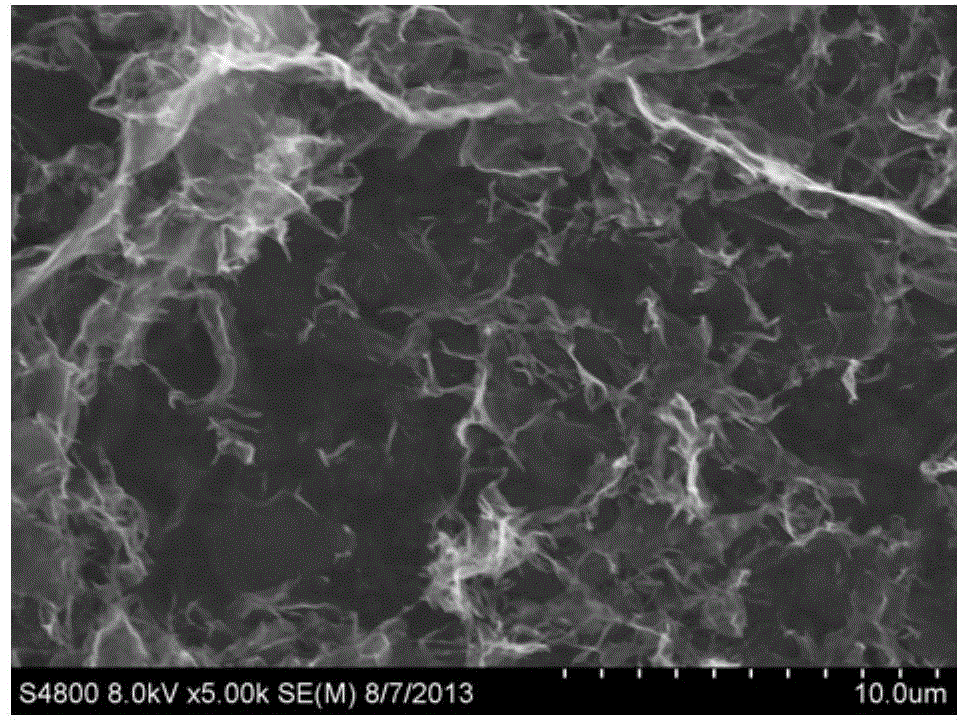

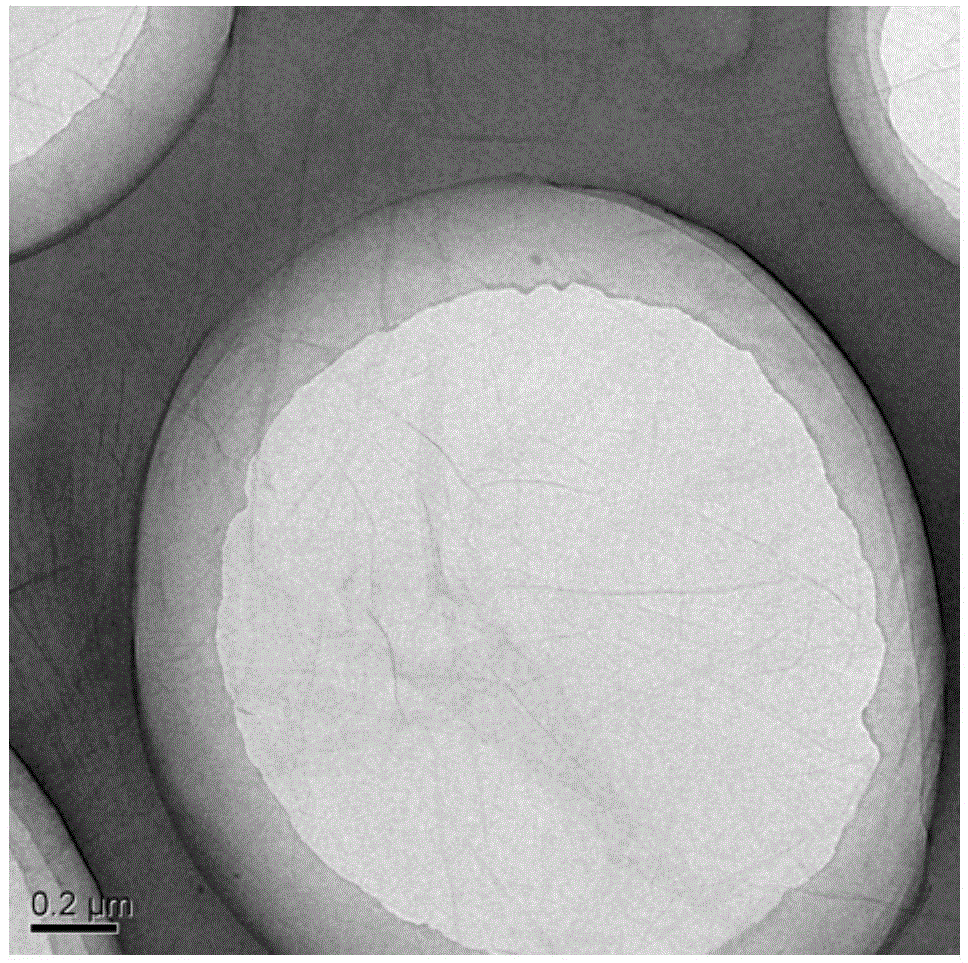

[0059] The present invention carries out Raman spectrum analysis with the graphene powder that embodiment 1 obtains, and the result is as follows figure 1 as shown, figu...

Embodiment 2

[0063] 10g particle size is 500 μm expanded graphite and 400g mass concentration is the concentrated sulfuric acid of 90% and mixes evenly, then adds the NaClO of 100g in the mixture that obtains 3 Carry out the first reaction at 60 DEG C for 24 hours to obtain graphite intercalation compound;

[0064] Add 50 g of aqueous hydrogen peroxide solution with a mass concentration of 60% to the graphite intercalation compound, and perform a second reaction at 180° C. to obtain a gray-black worm-like reaction product; filter the reaction product with a filter bag and wash with acetone To neutrality, an intermediate product is obtained;

[0065] Dispersing the intermediate product in water, performing ultrasonic peeling at 1000w for 20min to obtain a graphene solution; spray drying the graphene solution in a spray machine to obtain a graphene powder.

[0066] The graphene powder obtained in embodiment 2 is analyzed and tested according to the method described in embodiment 1, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com