Preparation method of hydrophobic nano-aerogel composite material

A technology of nano-airgel and composite materials, which is applied in the field of preparation of hydrophobic nano-airgel composite materials, which can solve the problems of high production cost, low utilization rate of hydrophobic modifier, loss of raw materials, etc., and achieve a smooth transition to the immersion environment , to avoid the loss of silica, the effect of controllable gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

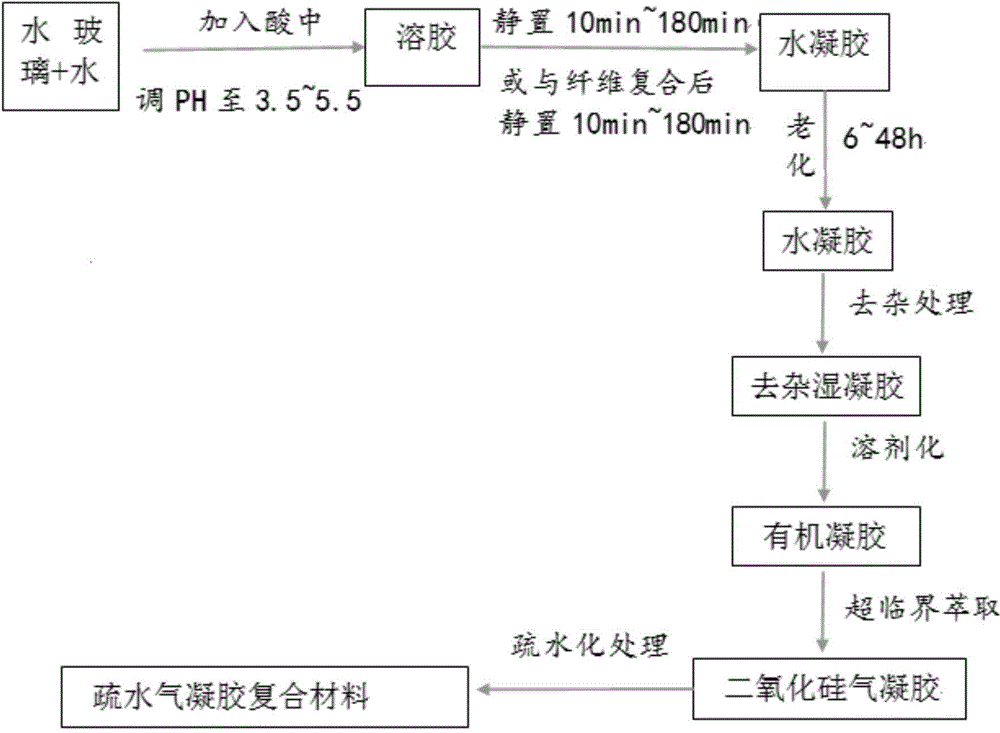

[0036] The preparation method of the hydrophobic nano airgel composite material of the present embodiment, such as figure 1 Shown is the process flow, which specifically includes the following steps:

[0037] 1) Take 100g of sodium water glass with a modulus of 2.0, mix it with water at a weight ratio of 1:3, and then slowly add it to the H + Concentration is in the 0.1L nitric acid solution of 8mol / L, and adding speed is 900ml / min, and stirring speed is 300 rev / min, and the pH value of adjusting mixed solution is 4.0;

[0038] 2) Add 100 g of glass fibers to the mixed solution obtained in step 1), disperse it evenly, and then let it stand for 10 minutes to obtain a hydrogel, and continue to stand and age the hydrogel for 48 hours to obtain an aged water gel. gel;

[0039] 3) soaking the aged hydrogel obtained in step 2) with deionized water for 4 times, each time for 5 hours; to obtain a wet gel with impurities removed;

[0040] 4) Soak the impurity-removing wet gel obtain...

Embodiment 2

[0045] The preparation method of the hydrophobic nano airgel composite material of the present embodiment specifically comprises the following steps:

[0046] 1) Take 100g of potassium water glass with a modulus of 3.3, mix it with water in a weight ratio of 1:6, and then add it to the H + Concentration is in the 0.12L nitric acid solution of 6mol / L, and adding speed is 600ml / min, and stirring speed is 400 rev / min, and the pH value of adjusting mixed solution is 4.5;

[0047] 2) Add 100 g of rock wool to the mixed solution obtained in step 1), disperse it evenly, and then let it stand for 180 minutes to obtain a hydrogel, and continue to stand and age the hydrogel for 6 hours to obtain an aged water gel. gel;

[0048] 3) Soak the aged hydrogel obtained in step 2) twice with deionized water for 5 hours each time; obtain a wet gel with impurities removed;

[0049] 4) soak the impurity-removing wet gel obtained in step 3) in isopropanol with a mass fraction of 50% for 2 hours, ...

Embodiment 3

[0053] The preparation method of the hydrophobic nano airgel composite material of the present embodiment specifically comprises the following steps:

[0054] 1) Take 100g of sodium water glass with a modulus of 2.6, mix it with water at a weight ratio of 1:5, and then add it to the H + In the 0.1L phosphoric acid solution with a concentration of 12mol / L, the addition speed is 1200ml / min, the stirring speed is 500 rpm, and the pH value of the mixed solution is adjusted to 5.5;

[0055] 2) Add 100 g of high-silica fiber to the mixed solution obtained in step 1), disperse it evenly, and then let it stand for 95 minutes to obtain a hydrogel, and continue to stand and age the hydrogel for 27 hours to obtain the aged the hydrogel;

[0056] 3) soaking the aged hydrogel obtained in step 2) with deionized water for 5 times, each time for 5 hours; to obtain a wet gel with impurities removed;

[0057] 4) Soak the impurity-removing wet gel obtained in step 3) in 40% ethanol for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com