Heat recycling type sludge fermentation tower

A heat recovery and fermentation tower technology, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of sludge emitting odor, long fermentation time, breeding of mosquitoes, etc., to facilitate transportation and subsequent recycling of resources, Shorten the fermentation start-up cycle and avoid the effect of inefficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

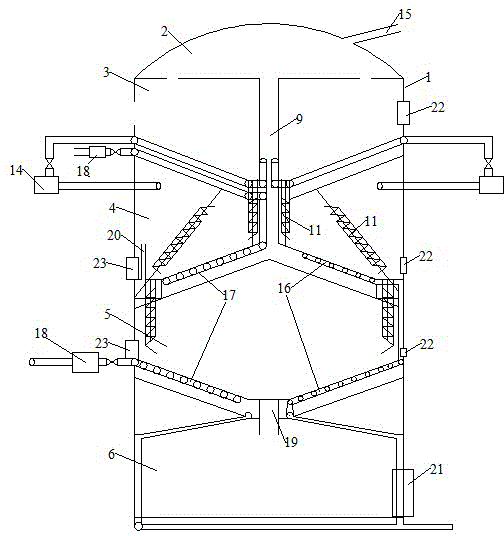

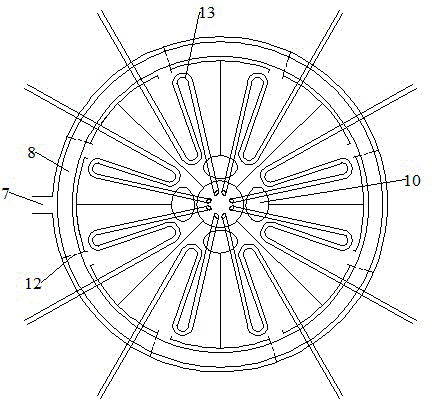

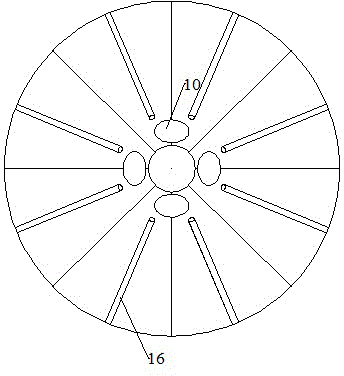

[0013] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. A heat recovery sludge fermentation tower. The interior of the tower body 1 is divided into tail gas collection and waste heat preservation area 2, feed and material preheating area 3, main fermentation area 4, cooling and secondary fermentation area 5 from top to bottom. and the storage area 6, the side wall of the tower body 1 of the feeding and material preheating area 3 is provided with a feed inlet 7, and the bottom of the feed inlet 7 is provided with an endless conveyor belt 8 that is close to the inner wall of the tower body 1, and the inside of the endless conveyor belt 8 The cavity is divided into a plurality of preheating chambers along the circumferential direction by the baffle plate fixed on the central air pipe 9, and the bottom plate of each preheating chamber is respectively provided with the main fermentation area 4 at the position ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com