Strontium chondroitin sulfate and its preparation method

A technology of chondroitin sulfate and sodium chondroitin sulfate, applied in the biological field, can solve the problems of poor prevention effect of osteoporosis and osteoarthritis, petechiae and hematoma, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

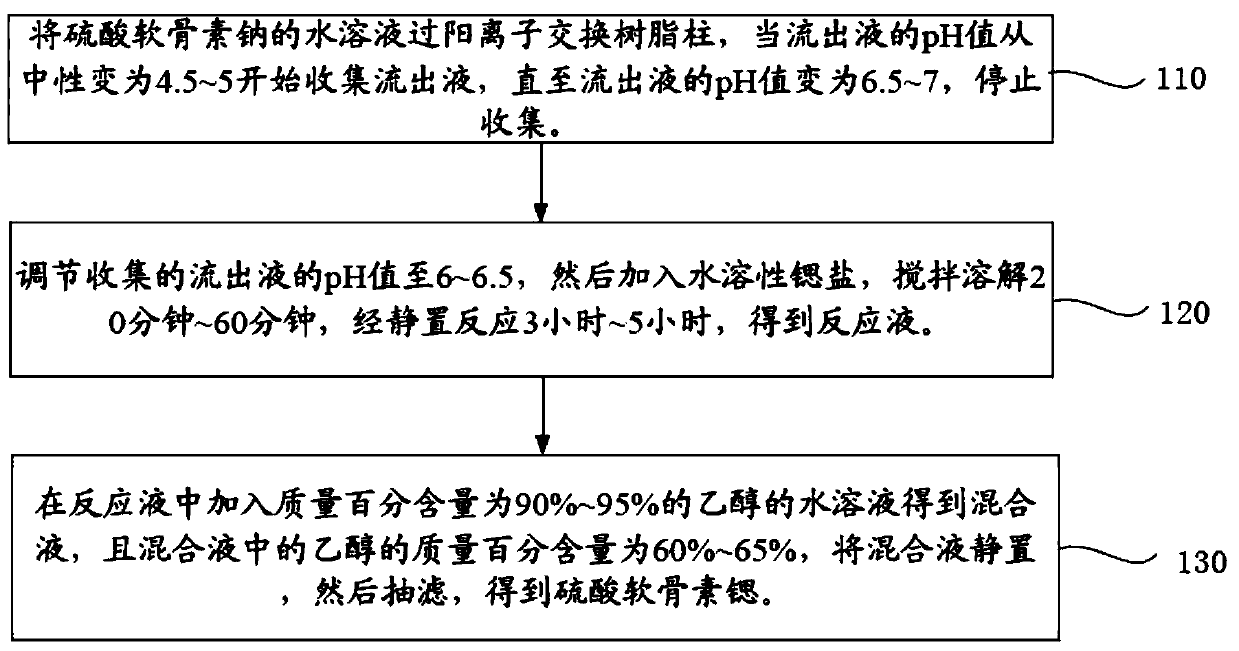

[0035] Such as figure 1 As shown, the preparation method of strontium chondroitin sulfate in one embodiment can be used to prepare the above-mentioned strontium chondroitin sulfate. The preparation method includes the following steps:

[0036] Step S110: Pass the aqueous solution of sodium chondroitin sulfate through a cation exchange resin column, start collecting the effluent when the pH of the effluent changes from neutral to 4.5-5, stop collecting until the pH of the effluent becomes 6.5-7.

[0037] Among them, sodium chondroitin sulfate can be purchased from the market; it can also be prepared by oneself.

[0038] Wherein, the preparation steps of sodium chondroitin sulfate are as follows: degrease the cartilage and pulverize it to obtain cartilage powder; mix the cartilage powder with deionized water, then add an alkalizing agent, and stir at 30°C to 40°C until the cartilage powder dissolves to obtain Cartilage solution; wherein, the mass ratio of alkalizing agent to ca...

Embodiment 1

[0056] The preparation steps of strontium chondroitin sulfate of the present embodiment are as follows:

[0057] (1) Preparation of sodium chondroitin sulfate: animal cartilage was boiled in deionized water at 80°C for 3 hours, after oil was removed, it was then boiled in deionized water at 80°C for 4 hours, cooled and then dried.

[0058] After the cartilage is degreased, it is pulverized to obtain cartilage powder. Put the cartilage powder in a reaction tank, add 5 times the deionized water of the cartilage and mix, then add sodium hydroxide according to the mass ratio of sodium hydroxide to cartilage is 0.01:1, and then Stir at 40°C until the cartilage powder dissolves to obtain a cartilage solution; use an aqueous solution of hydrochloric acid with a concentration of 3 mol / L to adjust the pH value of the cartilage solution to 8, and add trypsin according to the mass ratio of trypsin to cartilage of 0.0045:1, and add trypsin at 40 ℃ enzymatic hydrolysis for 4 hours, then wa...

Embodiment 2

[0064] The preparation steps of strontium chondroitin sulfate of the present embodiment are as follows:

[0065] (1) Preparation of sodium chondroitin sulfate: animal cartilage was boiled in deionized water at 100°C for 2 hours, after oil was removed, then boiled in deionized water at 100°C for 2 hours, cooled and then dried.

[0066] After the cartilage is degreased, it is pulverized to obtain cartilage powder. The cartilage powder is placed in a reaction tank, mixed with deionized water 30 times the amount of cartilage, and then sodium bicarbonate is added according to the mass ratio of sodium bicarbonate to cartilage of 0.5:1. Stir at 30°C until the cartilage powder dissolves to obtain a cartilage solution; use an aqueous solution of hydrochloric acid with a concentration of 4mol / L to adjust the pH value of the cartilage solution to 9, and add trypsin according to the mass ratio of trypsin to cartilage as 0.0055:1, and add trypsin at 50 ℃ enzymatic hydrolysis for 5 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com