Modified bisphenol-A epoxy resin inserted bar glue in complete underwater environment and preparation method

A technology for epoxy resin and underwater environment. It is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc. It can solve the problems of affecting the strength of the polymer, the molecular weight is reduced, and the curing agent cannot be cured, so as to achieve acid and alkali corrosion resistance. Excellent performance, simple preparation method, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Component A: 10 parts of bisphenol A epoxy resin, 1.8 parts of liquid polysulfide rubber, 5 parts of filler, mix and stir evenly. Component B: 4 parts of phenolic modified amine, 13 parts of filler.

Embodiment 2

[0029] Component A: 15 parts of bisphenol A epoxy resin, 2.5 parts of liquid polysulfide rubber, 10 parts of filler, mix and stir evenly. B component: 5 parts of phenolic modified amine, 15 parts of filler.

Embodiment 3

[0031] Component A: 9 parts of bisphenol A epoxy resin, 1.5 parts of liquid polysulfide rubber, 4 parts of filler, mix and stir evenly. Component B: 3 parts of phenolic modified amine, 5 parts of filler.

[0032] The obtained A component and B component are mixed according to the ratio of A:B mass ratio of 1:1 to obtain the rebar glue.

[0033] The usage method of the present invention:

[0034] When using it, mix it well according to the ratio of A:B=1:1 to get the rebar glue, then squeeze the obtained rebar glue into the hole to be anchored to achieve a predictable amount, and then rotate the rebar to be anchored into the hole , After the completion, it is forbidden to move the steel bars again, and wait for the glue to cure.

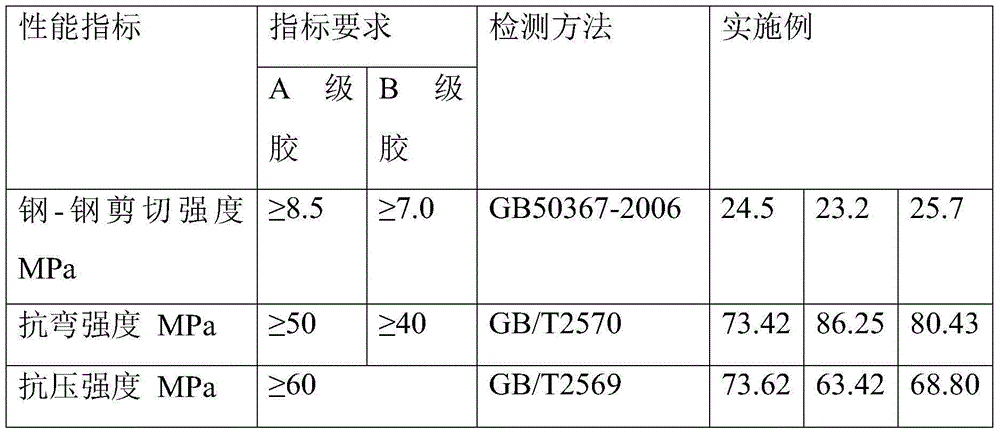

[0035] The performance test data of the prepared bar-planting glue of the present invention are shown in Table 1.

[0036] Table 1 Product performance test data table of the present invention

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com