Multi-core photoelectric composite watertight cable used for deep sea system

A photoelectric composite and watertight cable technology, applied in the direction of power cables, submarine cables, power cables including optical transmission components, etc., can solve the problems of large outer diameter, heavy weight, and no zero buoyancy effect of cables, and achieve excellent bending resistance Effects of performance, reduced weight, reduced attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and working principle of the photoelectric composite watertight cable will be described with reference to the drawings and embodiments.

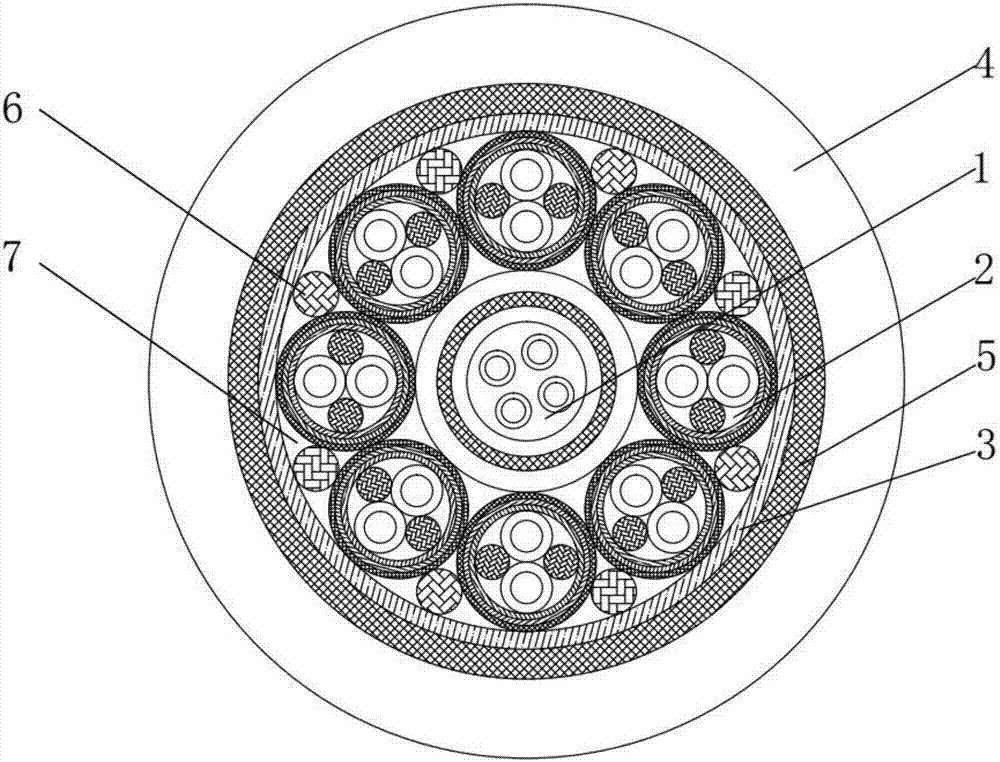

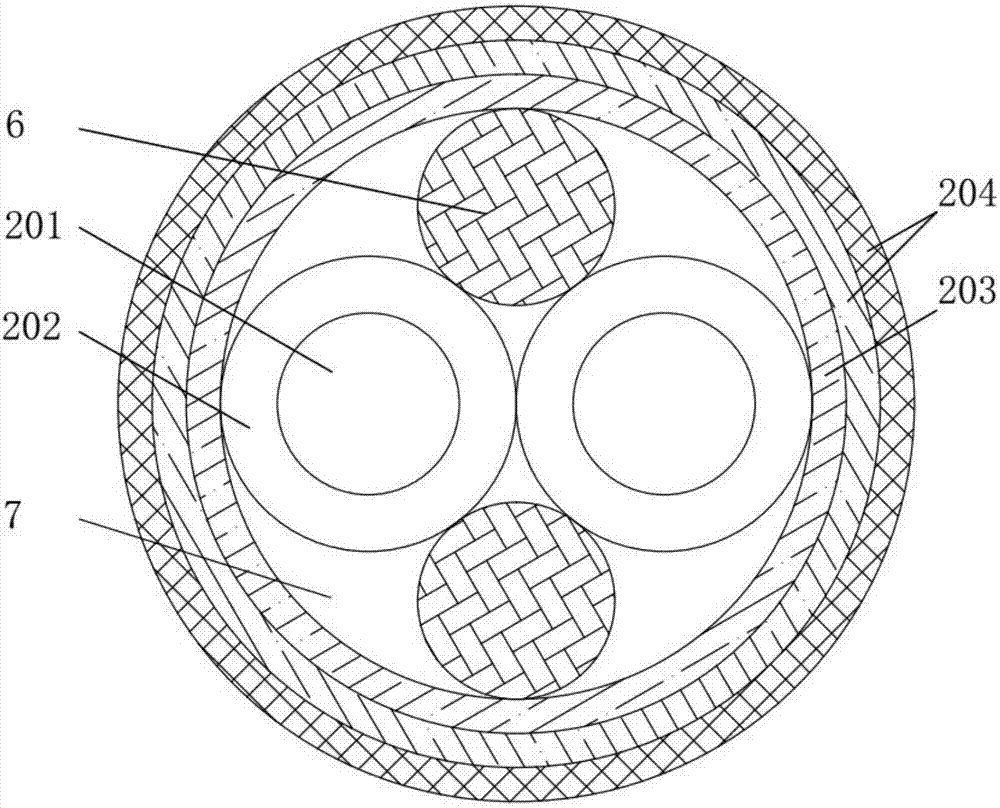

[0025] refer to figure 1 , the multi-core photoelectric composite watertight cable is composed of an optical unit 1 and 8 outer electrical units 2 twisted in the same direction, and the double-sided water-blocking tape with a thickness of 0.20mm is used as the wrapping layer 3, and 36 water-blocking wires are bundled. The tensile layer 5 is formed of nylon, and the outer sheath 4 is formed by double-layer co-extrusion of 2.0mm thick water-blocking sealant and polyurethane elastomer. In order to improve the water resistance and lateral pressure resistance of the cable, all the cable core gaps are filled with low-smoke and halogen-free filling strips 6 and water-blocking grease 7 .

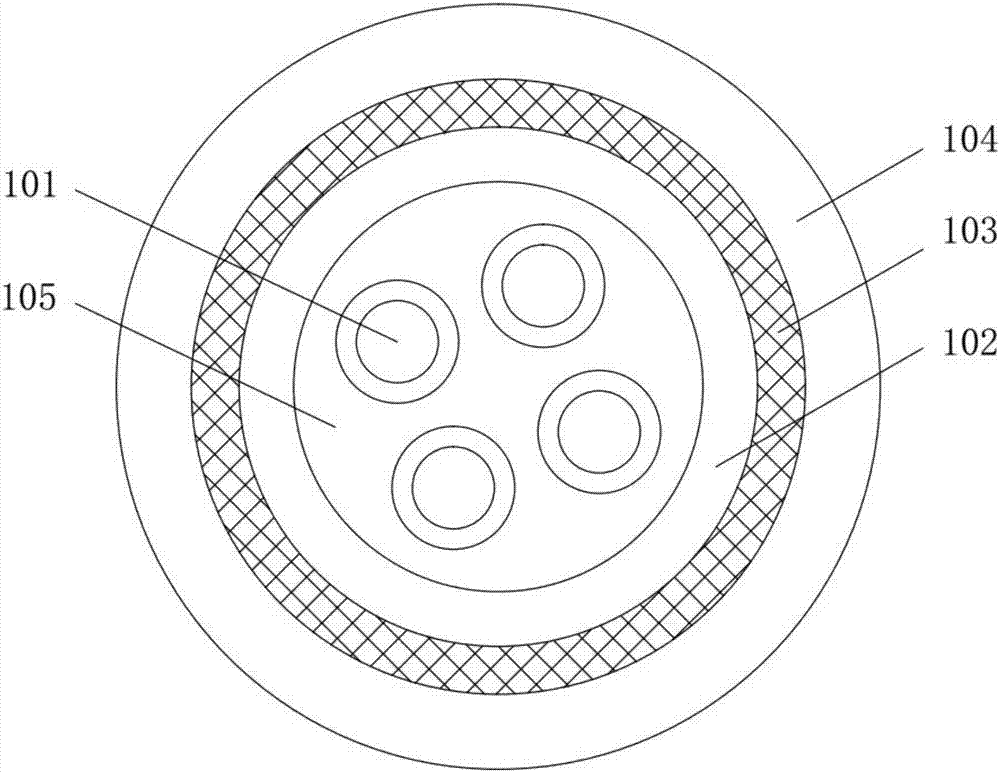

[0026] Among them, refer to figure 2 , the inner optical unit is composed of tight-packed optical fiber 101, inner sheath 102, shielding l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com