Solvent-free ultra-thick paste organic-inorganic hybrid nano-modified heavy-duty coating and preparation method thereof

A nano-modified, solvent-free technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex construction process and harsh curing conditions, achieve good construction performance, excellent adhesion, and save construction time and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A method for preparing a solvent-free ultra-thick organic-inorganic hybrid nano-modified heavy-duty anti-corrosion coating, specifically comprising the following steps:

[0050] Prepare Part A:

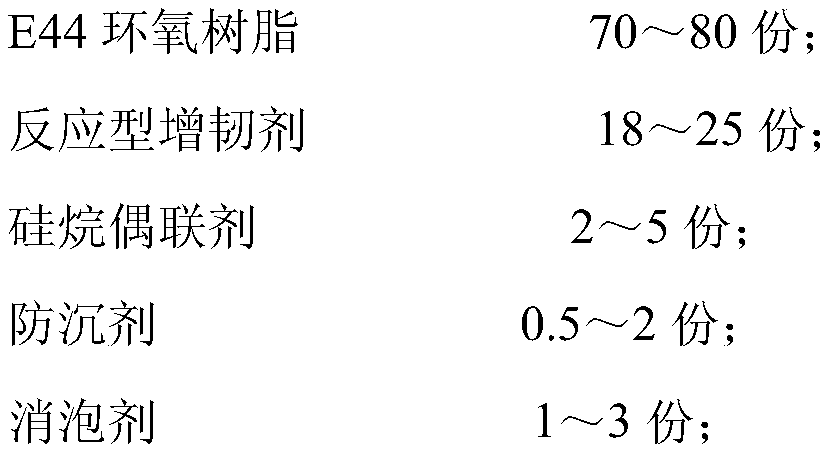

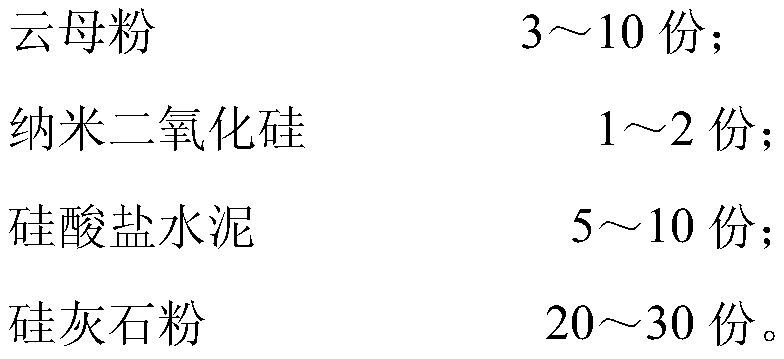

[0051] According to the parts by weight, weigh 70-80 parts of epoxy resin, 18-25 parts of reactive toughening agent, 2-5 parts of silane coupling agent, 0.5-2 parts of anti-settling agent, and 1-3 parts of defoaming agent , placed in a dispersing tank at a speed of 600-800r / min and dispersed for 15-20min, and filtered through a sieve to obtain component A;

[0052] Prepare Part B:

[0053] After the phenalkamine curing agent is filtered through a screen, component B is obtained;

[0054] Prepare component C:

[0055]The preparation method of the modified glass flakes is as follows: Add 200g of glass flakes into a dry flask containing 1.5L of anhydrous xylene, and at the same time add 0.15g of dimethyltin dilaurate, and disperse at room temperature for 40min at high speed to ...

Embodiment 1

[0061] Table 1 is the coating formula of embodiment 1

[0062]

[0063] A method for preparing a solvent-free ultra-thick organic-inorganic hybrid nano-modified heavy-duty anti-corrosion coating, comprising the following steps:

[0064] Step 1, preparation of component A:

[0065] Weigh 70 parts of epoxy resin, 25 parts of CYH-277 toughening agent, 3.5 parts of KH560 silane coupling agent, 0.5 parts of BEZ-75 anti-settling agent, 1 part of BYKA530 defoamer, and place them in a dispersion tank at 600-800r Disperse for 15 to 20 minutes at a rotating speed of 1 / min, and filter through a sieve to obtain component A, which will be used for later use;

[0066] Step 2, preparation of component B:

[0067] After the phenalkamine curing agent is filtered through a sieve, component B is prepared and set aside;

[0068] Step 3, preparation of component C:

[0069] The preparation method of the modified glass flakes is as follows: Add 200 g of glass flakes into a dry flask containi...

Embodiment 2

[0074] Table 2 is the coating formula of embodiment 2

[0075]

[0076] The preparation method of Example 2 is the same as that of Example 1, except that the specific materials and contents of each component are selected to be modified accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com