Filtering separation device for biomass pyrolytic heavy oil sludge and separation process thereof

A biomass pyrolysis, filtration and separation technology is applied in the field of filtration and separation devices and separation processes for biomass pyrolysis heavy oil sludge, which can solve the problems of increasing the viscosity and specific gravity of heavy oil, backward devices, and late start, and improve the oil yield. , save energy, avoid the effect of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

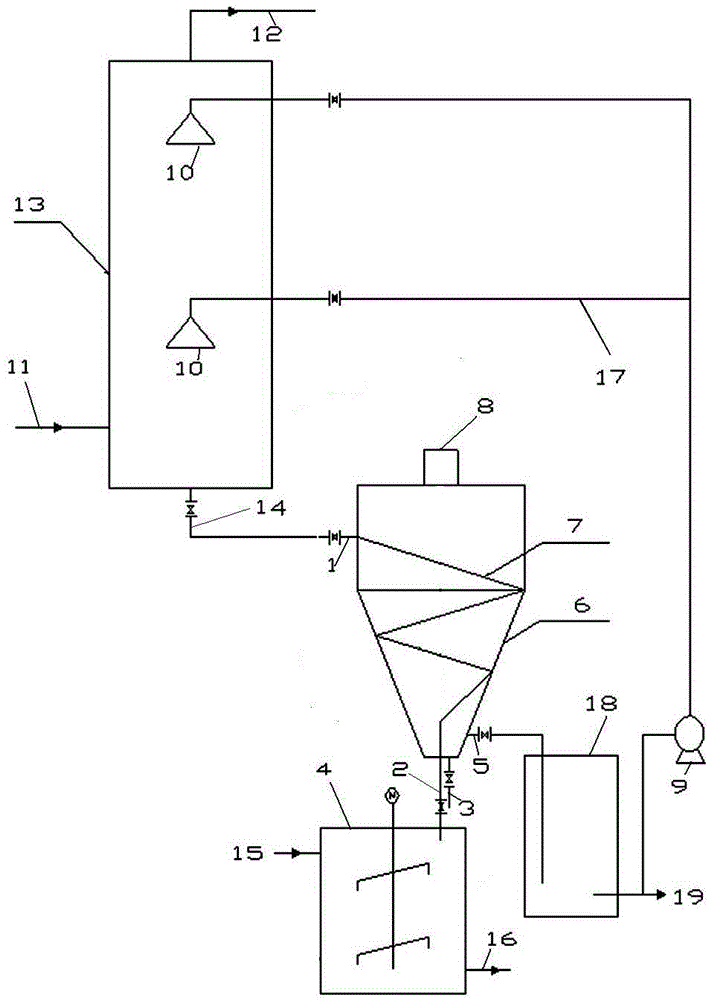

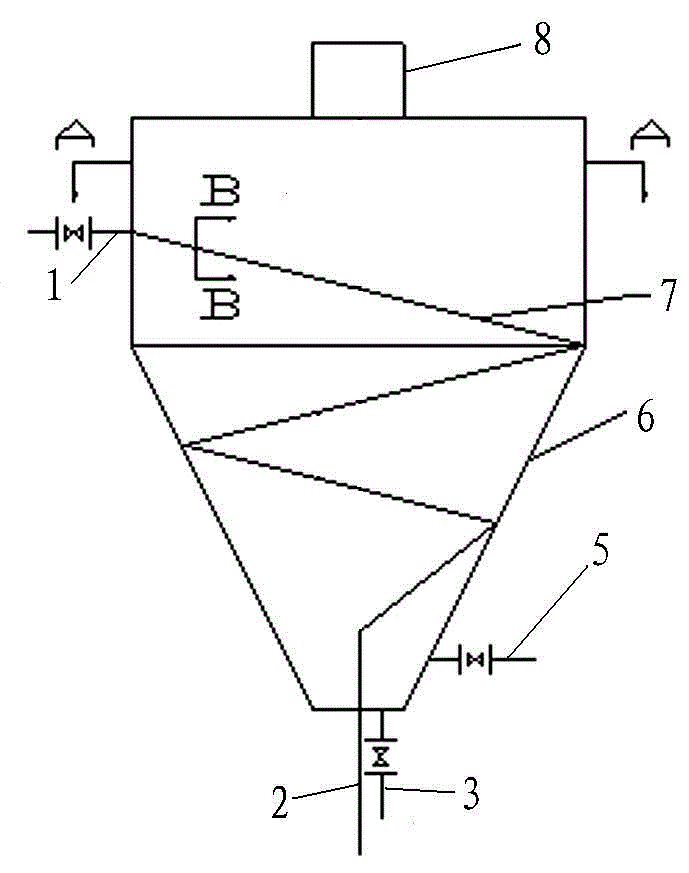

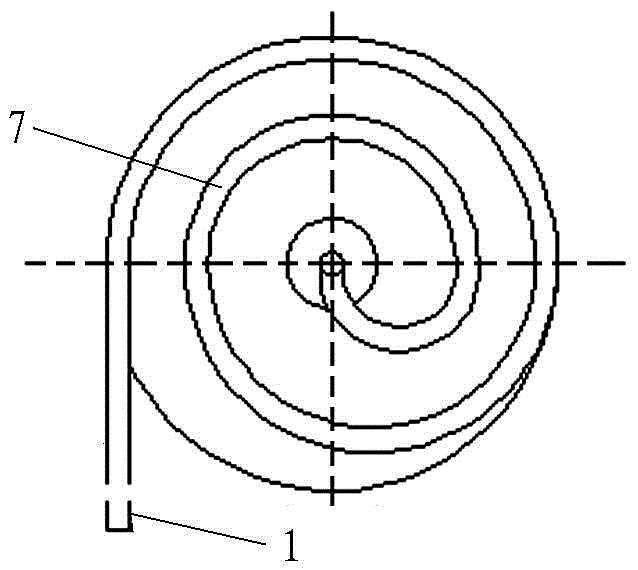

[0024] see Figure 1-4 , a filtration and separation device for biomass pyrolysis heavy oil sludge, mainly including a fractionation tower 13 connected by pipelines, a vertical centrifugal filter separator 6, an emulsification reaction kettle 4 and a heavy oil intermediate tank 18; the vertical centrifugal filter separator 6 is A hollow cylinder formed by connecting the upper cylinder and the lower cone; the hollow cylinder is provided with an insulation layer (preferably an insulation cotton layer with a thickness of more than 15 mm) on the outside of the hollow cylinder, and a heavy oil inlet 1 on the upper part. The continuous spiral filter channel 7 has a sludge outlet 2 at the bottom, and the heavy oil inlet 1 is connected to the upper inlet of the filter channel 7, and the sludge outlet 2 is connected to the lower end outlet of the filter channel 7; the inner wall of the vertical centrifugal filter separator 6 is from top to bottom A plurality of angle irons 20 are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com