Method for producing fibers having a low surface energy, and fibers, yarns and textiles having a low surface energy

A technology with low surface energy and manufacturing method, applied in the field of fiber manufacturing, can solve the problems of poor fiber water repellent effect, etc., and achieve the effects of shortening processing time, reducing equipment volume and cost, excellent liquid repellency and antifouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

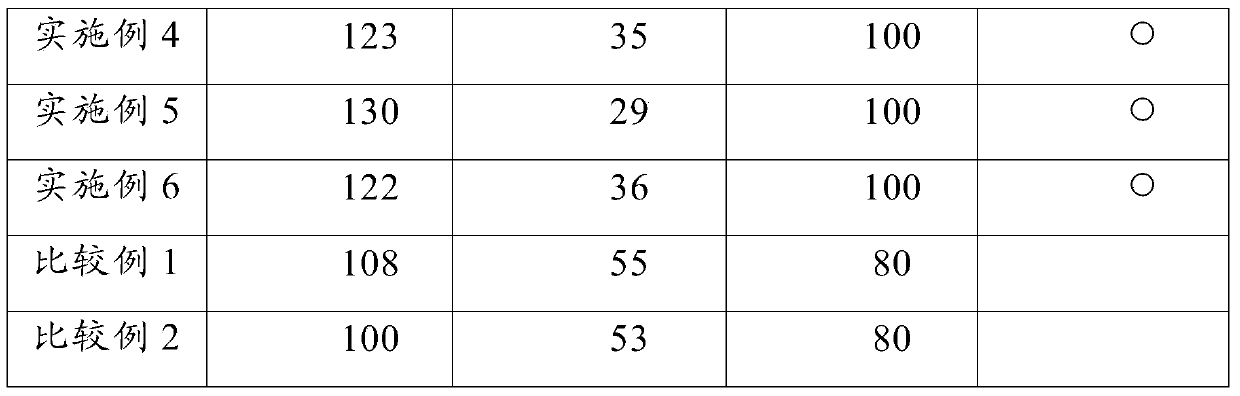

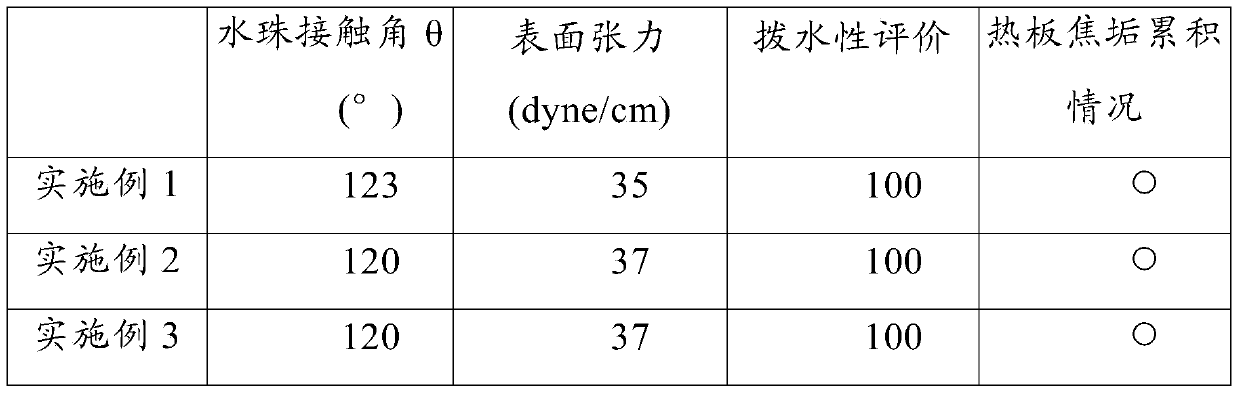

[0035]The polyethylene terephthalate (A) particle and the polyethylene terephthalate (B) particle of fluorine-containing low surface energy additive (manufactured by GOULSTON company, product name FC-L624) 30wt% according to A / B=90 / 10 ratio blending, melt spinning at 288°C with a spinning speed of 2800m / min, and then a false twisting process with a coiling speed of 600m / min, a hot plate temperature of 230°C, and an elongation ratio of 1.75 (DTY ) to obtain fibers containing 3wt% low surface energy additives. The obtained fibers were woven into a fabric, and the surface tension value, water bead contact angle and water repellency test characteristics of the fabric were measured, and the results are shown in Table 1.

Embodiment 2

[0037] The polyethylene terephthalate (A) particle and the polyethylene terephthalate (B) particle of fluorine-containing low surface energy additive (manufactured by GOULSTON company, product name FC-L624) 30wt% according to A / B=90 / 10 after blending, melt spinning at 288°C with a spinning speed of 2800m / min, and then fully drawn yarn with a spinning speed of 4000m / min, an extension temperature of 85°C, a setting temperature of 130°C and an elongation ratio of 2.1 Fibers containing 3wt% low surface energy additives were prepared by manufacturing process. The obtained fibers were woven into a fabric, and the surface tension value, water bead contact angle and water repellency test characteristics of the fabric were measured, and the results are shown in Table 1.

Embodiment 3

[0039] The polyethylene terephthalate (A) particle and the polyethylene terephthalate (B) particle of fluorine-containing low surface energy additive (manufactured by GOULSTON company, product name FC-L624) 30wt% according to A / B=90 / 10 after blending, at the melting temperature of 288 ℃, the fiber containing 3wt% low surface energy additive was prepared by the HOY process with a spinning speed of 4500m / min. The obtained fibers were woven into a fabric, and the surface tension value, water bead contact angle and water repellency test characteristics of the fabric were measured, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com