Heat pump system for heating drying medium and recovering waste heat in stepped mode

A technology of drying medium and heat pump system, which is applied in the directions of heat pump, heating device, lighting and heating equipment, etc., can solve the problems of reducing the energy efficiency ratio of heat pump system, low energy efficiency ratio of heat pump application, difficult to digest heat pump system equipment cost, etc. Energy efficiency ratio, the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

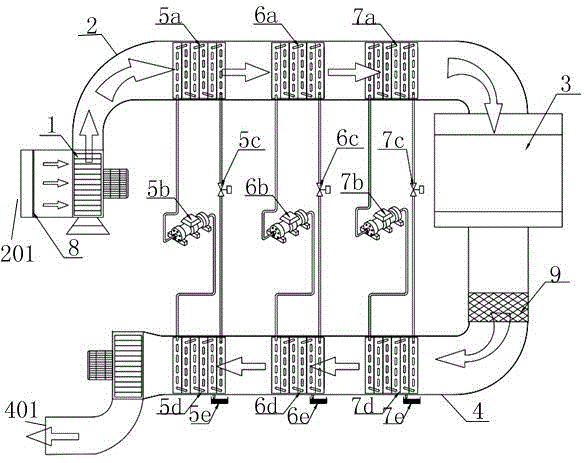

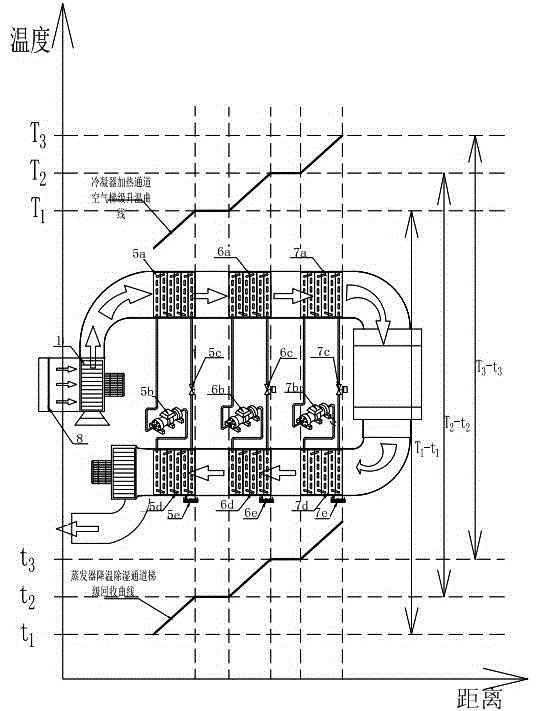

[0075] refer to Figure 1-4 , the present invention provides a heat pump system for waste heat cascade recovery and drying medium cascade heating, including a drying room 3, a drying medium inflow channel 2 and a drying medium outflow channel 4, the drying medium inflow channel 2 and the drying medium outflow channel 4 are connected to each other The drying room is connected in 3 phases.

[0076] Among them, the drying medium is a medium that can carry heat and transfer heat to heat the wet material and promote the evaporation of moisture in the wet material. The specific drying medium used is not limited here, and air, nitrogen, carbon dioxide, etc. can be used.

[0077] If the drying medium indirectly heats the wet material placed in the heat exchanger through the partition wall heat exchanger to promote the evaporation of moisture in the wet material, the drying medium can also use water vapor, heat transfer oil, water, etc. In this case , the channel where the evaporator ...

Embodiment 2

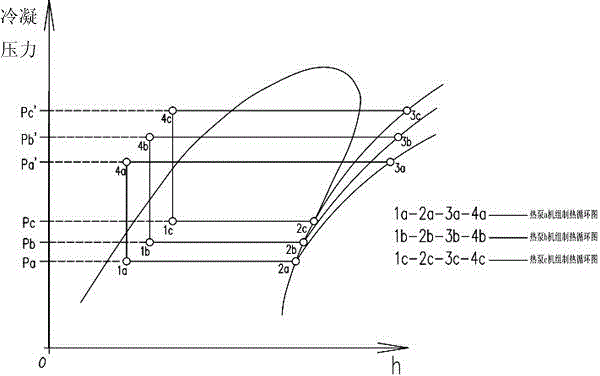

[0103] refer to Figure 6-7 , the heat pump system includes several heat pump units, and each heat pump unit includes a condenser, an evaporator, a compressor, and a throttle valve; 2, the evaporators in at least one group of heat pump units are located in the drying medium outflow channel 4, and the evaporators in at least one group of heat pump units are located outside the drying medium outflow channel 4 (that is, in the external environment), and the evaporators are located in the external environment Corresponding to the condenser in the heat pump unit, it is located between the inlet 201 of the drying medium inflow channel 2 and the evaporator is located in the drying medium inflow channel 2 and corresponds to the condenser in the heat pump unit. limit.

[0104] In the following, 5 sets of heat pump units are used for detailed description. The evaporators of the three sets of heat pump sets are located in the drying medium outflow channel 4, and the evaporators of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com