A method and device for micron-scale zonal sampling suitable for capillary

A sampling device and capillary technology, applied in the field of separation and analysis in analytical chemistry, can solve the problems of increasing sample loss, increasing the difficulty of analyzing precious samples, prolonging the analysis process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, sampling device

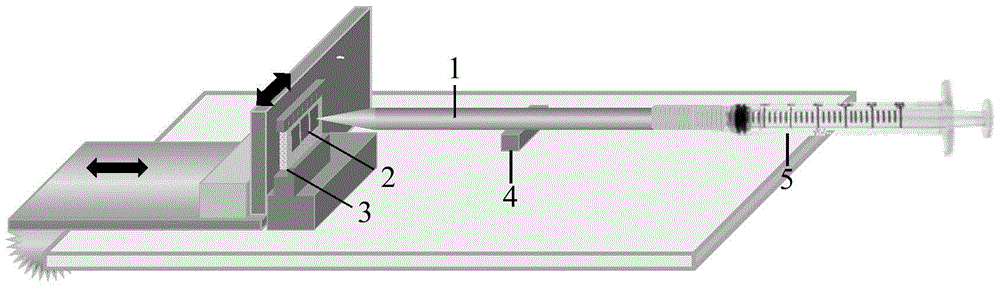

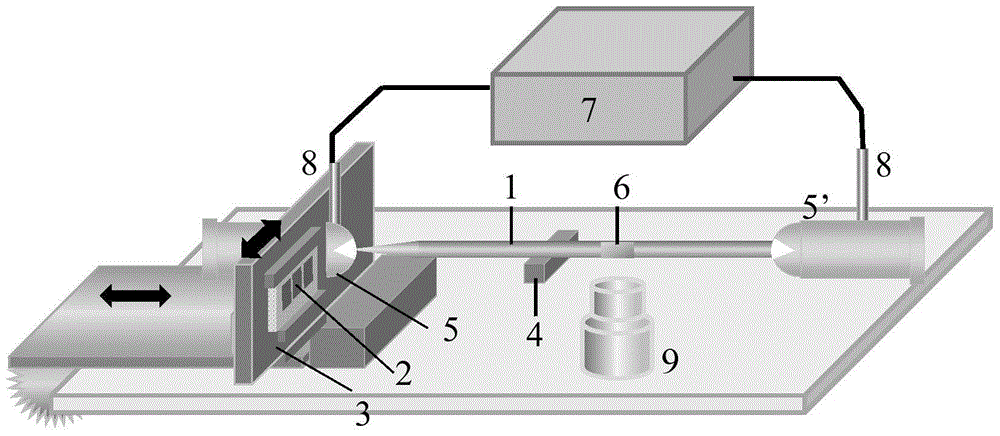

[0046] The structure of the sampling device provided by the invention is as figure 1 As shown, it consists of a quartz capillary 1, a detachable sample loading plate 2, a displacement control mechanism 3, a capillary cleaning mechanism that is a syringe 5 and a capillary holder 4;

[0047] Wherein, the inner diameter of the quartz capillary 1 is 50 μm, the outer diameter is 375 μm, and the length is 5 cm; one end of the capillary is a sharpened sampling end, and is hydrophobized with octadecyl silicon chloride; the quartz capillary points vertically to the sample plate, The other end is connected to the capillary cleaning mechanism, that is, the syringe;

[0048] The sample adding plate 2 is a glass sheet, which is placed on the displacement control mechanism, and a groove of 1 cm × 1 cm × 200 μm is etched with HF on it as a sample adding slot; the number of sample adding slots is three;

[0049] The displacement control mechanism 3 is ...

Embodiment 2

[0051] Embodiment 2, sampling and effect of FITC liquid sample

[0052] 1) Using the sample injection device of Example 1, the inner wall of the capillary is cleaned with the capillary cleaning mechanism, that is, the syringe 5, and then the buffer capable of dissolving the sample is sucked or pressed into the capillary until the entire tube is filled.

[0053] The sample plate 2 was cleaned with Piranha solution and treated with air plasma to make it hydrophilic.

[0054] 2) Configure the FITC liquid sample as follows:

[0055] Use 5 mM borax aqueous solution with a pH value of 9.2 as a solvent, dissolve FITC in the solvent to a concentration of 0.1 mM; take 1 μL of the above solution as a FITC liquid sample;

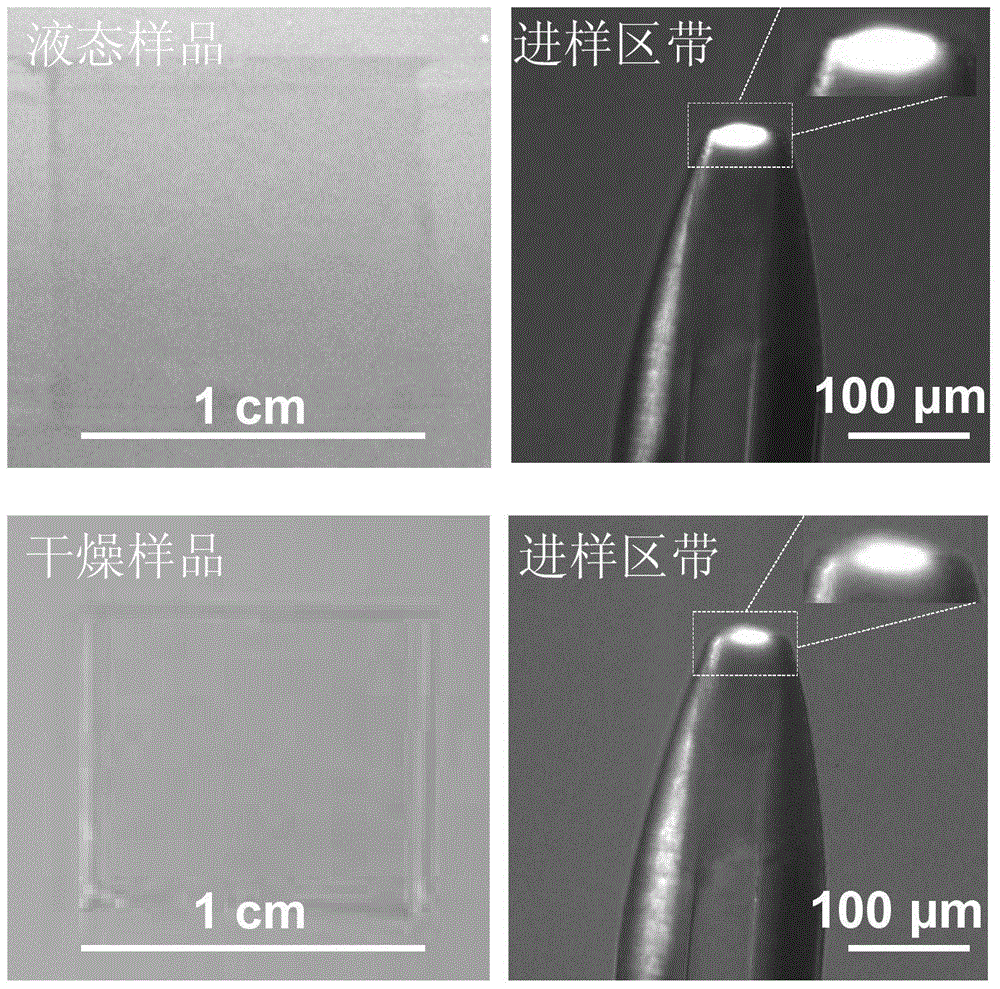

[0056] 3) Drop the FITC liquid sample obtained in step 2) into a 1 cm × 1 cm × 200 μm sampling tank on the sample loading plate 2, spread it out, and obtain a sample liquid film with a thickness of 10 μm, such as figure 2 (upper left);

[0057] Fix the sample addin...

Embodiment 3

[0059] Example 3, Sampling and effect of FITC solid sample

[0060] Utilize the sampling device of embodiment 1, the FITC liquid sample used in embodiment 2 is dripped in the sampling tank of sample loading plate 2, after spreading out, let it volatilize and dry naturally (such as figure 2 Shown in the lower left), obtain FITC solid sample;

[0061] Afterwards, the sample loading plate 2 was placed on the displacement control mechanism 3 for sample injection, and the contact time was 0.2s.

[0062] Using a fluorescence microscope to observe the sample injection zone, it can be known that the length of the sample injection zone is 8 μm, as figure 2 Shown below right. The length of the sampling zone can be adjusted by the length of contact time between the capillary and the solid sample surface. It can be seen from the figure that the sample injection of FITC solid samples can be realized by using the sample injection device of Example 1.

[0063] The same can be done by c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com