A new type of battery capacitor based on composite positive and negative electrode materials

A technology for battery capacitors and negative electrode materials, applied in the direction of electrolytic capacitors, hybrid capacitors, hybrid capacitor electrodes, etc., can solve the problems of restricting power performance and cycle life, difficulty in fast charging and discharging, long-term use, and low electronic conductivity. Improve the rate performance, enhance the conductivity, and meet the needs of high-current charging and discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

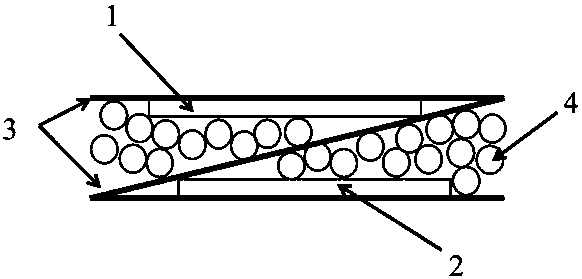

[0025] figure 1 For a simplified schematic diagram of the battery cell, only the composition of the present invention is schematically described. figure 1 The new battery capacitor shown includes a positive pole piece 1 and a negative pole piece 2 . Both sides of the positive and negative plates are evenly coated with the slurry mixed with lithium manganate (lithium titanate), activated carbon, binder and conductive agent. The diaphragm 3 completely wraps and isolates the positive and negative pole pieces in the form of a "Z", and the electrolyte 4 fills the structure of the battery capacitor and infiltrates the positive and negative pole pieces and the diaphragm.

[0026] The preparation process of the present invention is as follows:

[0027] Lithium manganate, activated carbon, conductive agent (SuperP+graphene), and binder (PVDF) were weighed according to the mass ratio of 88:5:3:4 and dissolved in nitrogen methyl pyrrolidone. Stir for 4 hours to form a uniform slurry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com