Novel high-current-density fast recovery diode structure and manufacturing method thereof

A technology with high current density and recovery diodes, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve limited problems, increase economic benefits, increase device junction area, and reduce device active area area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

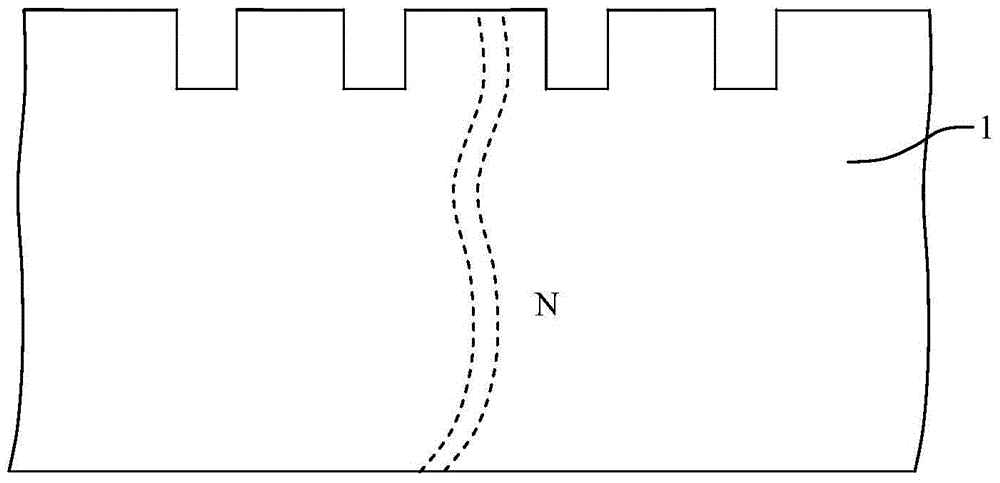

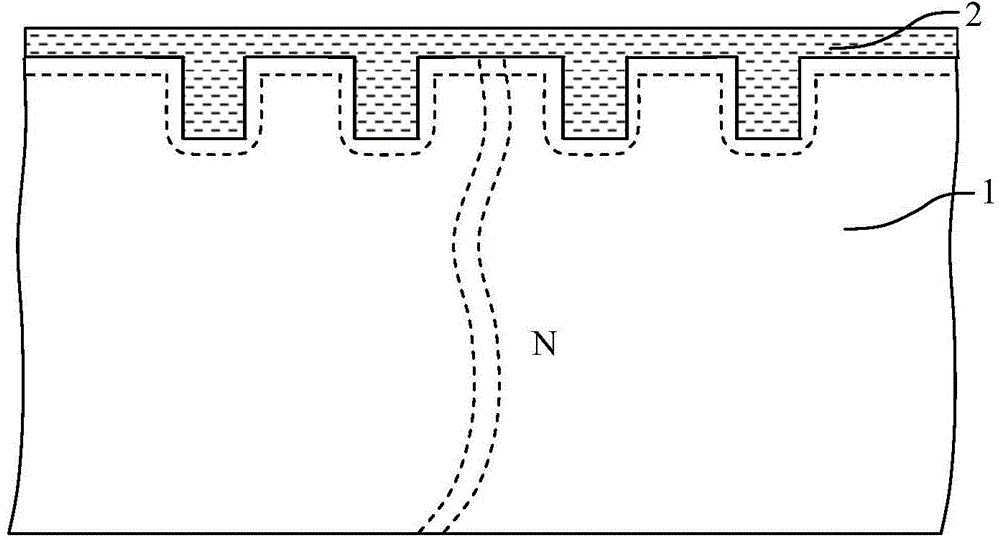

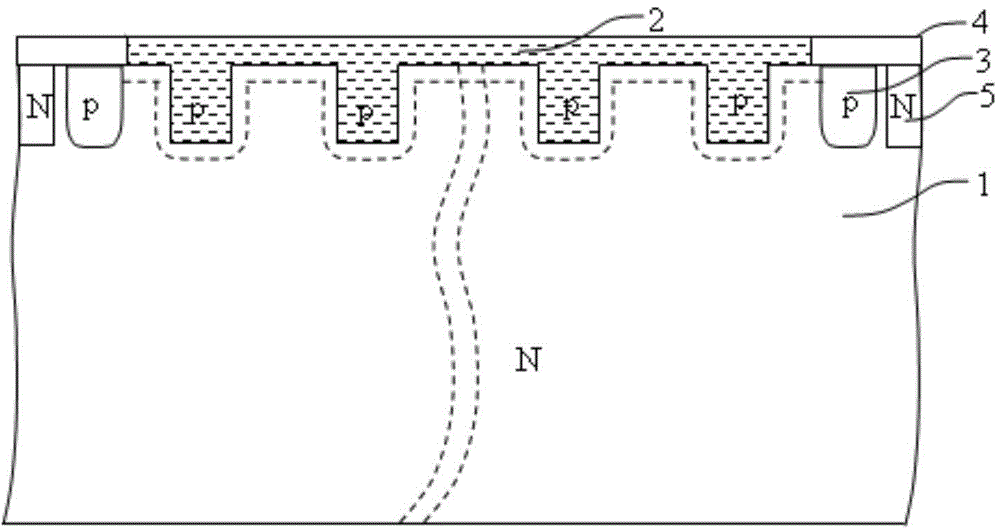

[0028] The basic idea of the present invention is to provide a new type of high current density fast recovery diode structure, aiming at the problems of relatively low current density and low current capacity of the existing conventional planar junction devices, through trenching technology combined with boron-doped polysilicon deposition The formation of the grooved anode region can significantly increase the junction area of the anode active region compared with the conventional planar structure, increase the current density of the device, save the chip area and improve economic benefits under the same current. Heavily doped polysilicon can form a good ohmic contact with the N-type substrate, improving device reliability.

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] like figure 1 and Figure 4 As shown, a new type of high current density fast recovery diode structure, including (1) N-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com