Layered O3-phase nickel oxide-contained positive electrode material and preparation method and application thereof

A technology of nickel oxide and positive electrode materials, applied in the field of materials, can solve problems such as instability, and achieve the effects of low cost, suitable voltage range, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

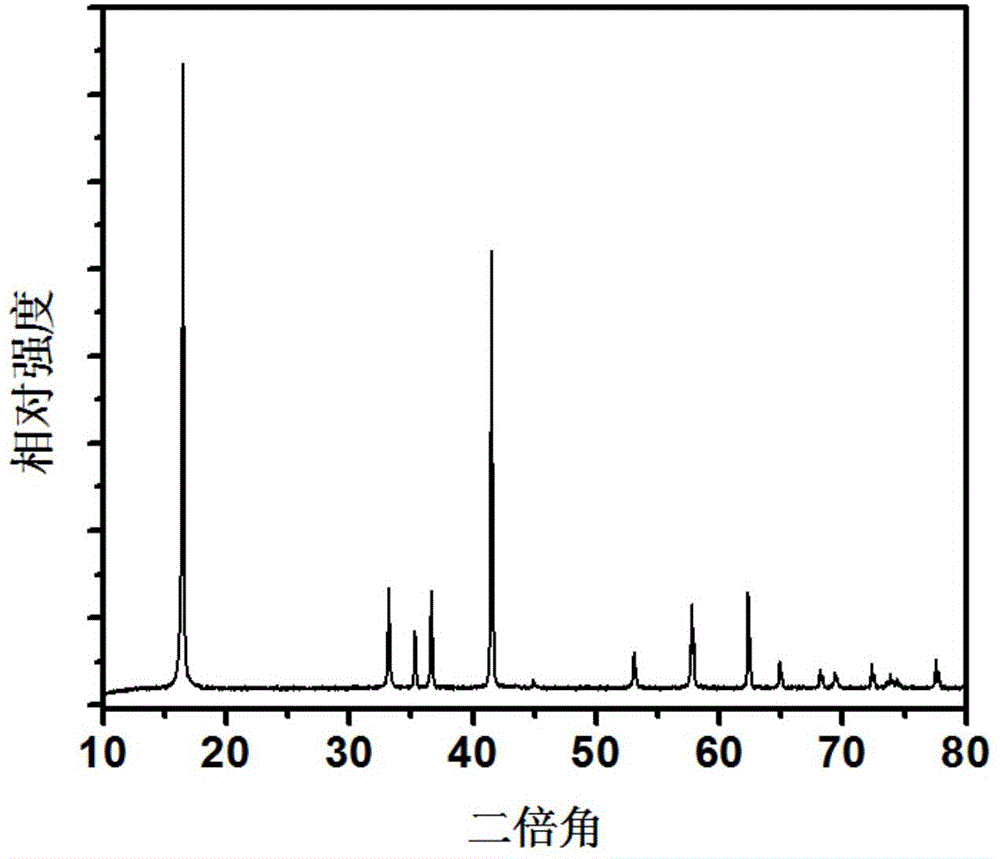

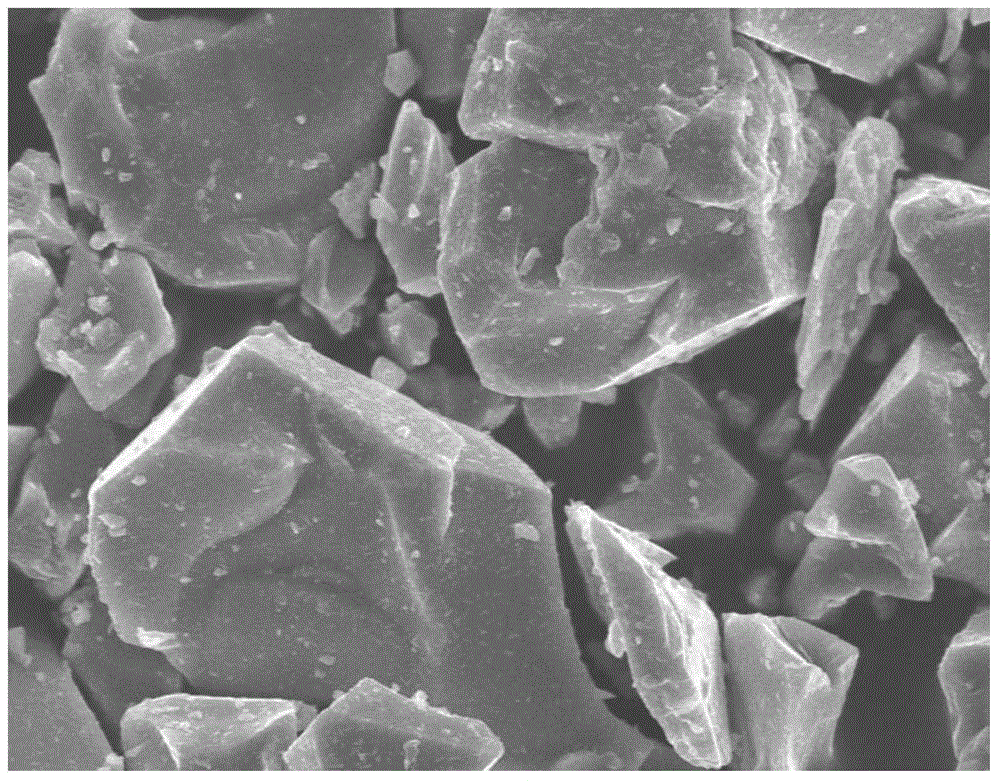

[0038] Example 1 of the present invention provides a layered O3 phase nickel-containing oxide cathode material, the chemical formula of which is: Na x A a Ni b Ti c O 2-δ ;

[0039] Wherein, Ni and Ti are transition metal elements, A is an element for doping and replacing the transition metal sites; the A is Li + , Mg 2+ , B 3+ , Cu 2+ , Zn 2+ , Co 3+ , Al 3+ , V 3+ , Fe 3+ , Mn 3+ , Mn 4+ One or more of; the valence state of A is m, and the relationship between x, a, b, c, δ and m satisfies x+ma+2b+4c=2(2-δ), And satisfy a+b+c=1; among them, 0.75 <x <1, 0 <a <0.6, 0 <b <0.5, 0 <c <0.6, -0.05 <δ <0.05.

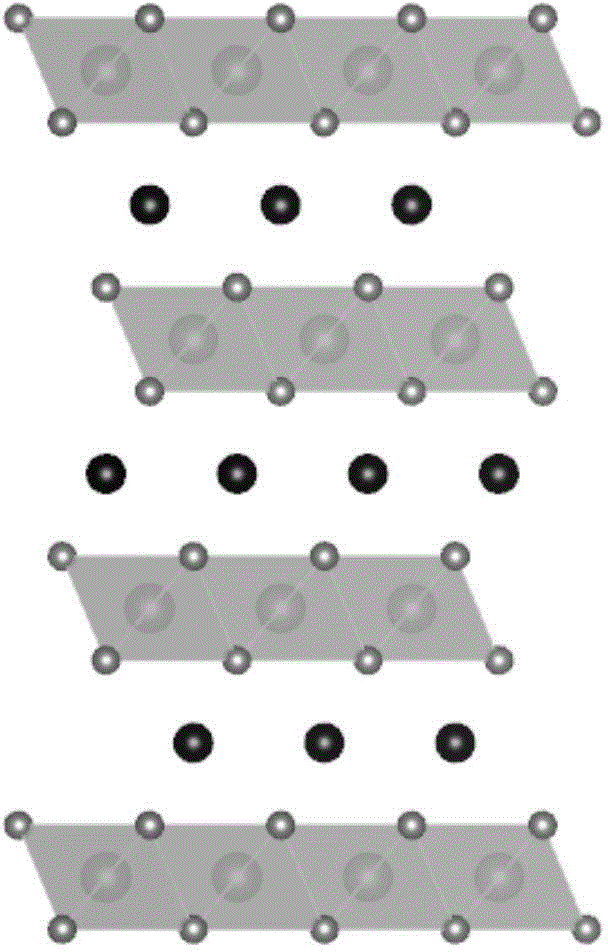

[0040] In Na x A a Ni b Ti c O 2-δ In the structure, Ni, Mn, and A form an octahedral structure with the six nearest neighboring oxygen atoms, and a plurality of the octahedral structures are arranged on the same side to form a transition metal layer; the six oxygen atoms in the two transition metal layers Forms octahedral structure, alkali metal ion Na + It is located between ever...

Embodiment 2

[0046] This embodiment provides a method for preparing a layered O3 phase nickel-containing oxide cathode material, specifically a solid phase method, such as Figure 4 Shown, including:

[0047] Step 401: Mix the required stoichiometric amount of sodium from 102wt% to 105wt% of sodium-containing carbonate and the required stoichiometric amount of doped metal oxide and A oxide according to the stoichiometric ratio of the positive electrode active material, and grind uniformly The precursor powder is obtained;

[0048] Specifically, the A is Li + , Mg 2+ , B 3+ , Cu 2+ , Zn 2+ , Co 3+ , Al 3+ , V 3+ , Fe 3+ , Mn 3+ , Mn 4+ One or more of.

[0049] Step 402: Place the obtained precursor powder in a crucible, heat-treat it in an air atmosphere at 900°C to 1000°C for 5 to 24 hours, and grind to obtain the layered oxide material.

[0050] The preparation method provided in this embodiment can be used to prepare the layered O3 phase nickel-containing oxide cathode material described in the ...

Embodiment 3

[0052] This embodiment provides a method for preparing a layered O3 phase nickel-containing oxide cathode material, specifically a sol-gel method, such as Figure 5 Shown, including:

[0053] Step 501: Dissolve the required stoichiometric amount of sodium acetate of 102% to 105% by weight of sodium ion and the required stoichiometric amount of nickel nitrate (such as nickel nitrate), tetrabutyl titanate and A nitrate. In absolute ethanol or deionized water, and add citric acid to form a precursor gel;

[0054] Specifically, the A is Li + , Mg 2+ , B 3+ , Cu 2+ , Zn 2+ , Co 3+ , Al 3+ , V 3+ , Fe 3+ , Mn 3+ , Mn 4+ One or more of.

[0055] Step 502, placing the precursor gel in a crucible, and pretreating for 2 to 6 hours in an air atmosphere at 250°C to 500°C to obtain a pretreated powder;

[0056] Step 503: Heat the pretreated powder at 800°C to 1000°C for 5 to 20 hours, and grind to obtain the layered oxide material.

[0057] The preparation method provided in this embodiment can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com