Method for producing silicon-containing particles for anode active material for non-aqueous electrolyte secondary battery, anode member for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and silicon-containing particles for anode active material for non-aqueous electrolyte secondary battery

A negative electrode active material, non-aqueous electrolyte technology, applied in non-aqueous electrolyte storage batteries, active material electrodes, secondary batteries, etc., can solve problems such as unfavorable cost, failure to propose a manufacturing method, etc., and achieve long life, high battery capacity, High volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

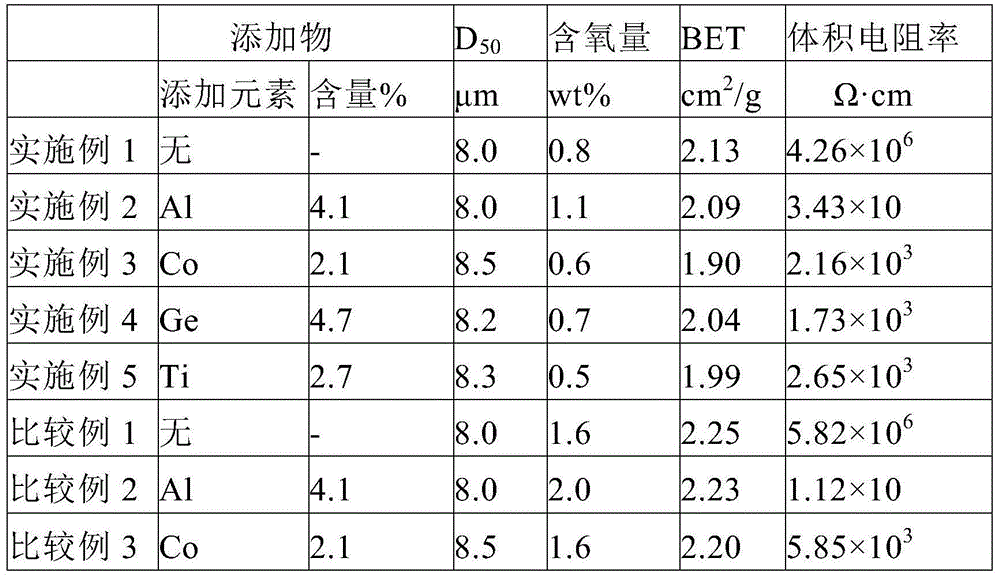

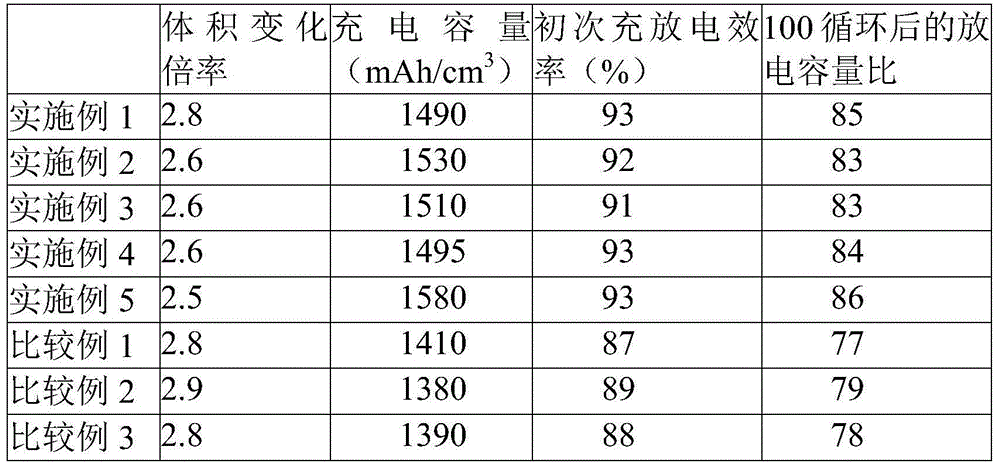

Embodiment 1

[0127] Inside the vacuum chamber with an exhaust device composed of an oil diffusion pump, a motorized booster pump and an oil rotary vacuum pump, a copper crucible with a carbon hearth lining with a thickness of 20 μm is set, and 8 kg of metal silicon blocks are dropped in. The chamber is depressurized. The arrival pressure after 2 hours is 2×10 -4 Pa.

[0128] Next, use the electron beam straight-forward electron gun installed in the chamber to start melting the metal silicon block. After the metal silicon block is melted, use the power of 120kW and the electron beam area 2 , continue to carry out evaporation for 2 hours. In vapor deposition, the temperature of the vapor deposition substrate made of stainless steel was controlled at 600°C. The chamber was opened to obtain 3.5 kg of evaporated silicon block.

[0129] Using a jet mill (KJ-25 (trade name) manufactured by KURIMOTO, LTD.), the manufactured vapor-deposited silicon was pulverized and classified to obtain D 50 ...

Embodiment 2

[0131]Silicon-containing particles were obtained in the same manner as in Example 1 except that 8 kg of metal silicon lumps containing 5.0% by mass of aluminum were introduced instead of 8 kg of metal silicon lumps. The silicon-containing particles obtained by the vapor deposition method were heat-treated for 3 hours in an electric furnace having an alumina furnace tube kept at 800°C under a 10%-acetylene / Ar flow. The obtained silicon-containing particle for the negative electrode active material for the non-aqueous electrolyte secondary battery is D 50 =8.0μm, oxygen content 1.1%, BET specific surface area 2.09m 2 / g.

Embodiment 3

[0133] Silicon particles obtained by vapor deposition were obtained in the same manner as in Example 1 except that 8 kg of metal silicon lumps containing 5% by mass of cobalt were put in instead of 8 kg of metal silicon lumps. The silicon-containing particles obtained by vapor deposition were heat-treated for 3 hours under a reduced pressure of 200 Pa in an electric furnace with an alumina furnace tube kept at 800° C. under a 10%-acetylene / Ar flow. The obtained silicon-containing particles for the negative electrode active material of the non-aqueous electrolyte secondary battery are D 50 =8.5μm, oxygen content 0.6%, BET specific surface area is 1.90m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com